Fans in cooling towers are responsible for efficiently dissipating heat to the environment; in particular, heat generated when a process, system or building is cooled using water. At the same time, the fans that are used must be extremely rugged because they have to withstand high humidity levels, various environmental influences and rapid changes in temperature. And last but not least, they must be as quiet as possible – particularly if the cooling towers are located near residential areas or mixed-use zones. Several smaller fans provide benefits: flexibly arranged for a compact design and consistant air distribution.

See what an efficient retrofit of a cooling tower can look like at KINFIT:

The retrofit was completed in just seven hours. One belt-driven AC fan was replaced by two efficient AxiBlade fans. The result: energy savings of more than 50 percent. (Video | ebm-papst)

More fans, more benefits: the FanGrid

With conventionally structured cooling towers, it is becoming more and more difficult to satisfy these requirements completely. In order to generate high air flow, very large fans are typically used. They are driven by transmissions or belts from an AC motor. Due to the weight of the large single fans, they have a solid design and cannot be installed until they reach the construction site. This makes it virtually impossible to precisely balance the rotating impeller, which frequently leads to premature failures in operation. Such fans often run in two-phase, star/delta or on/off operation.

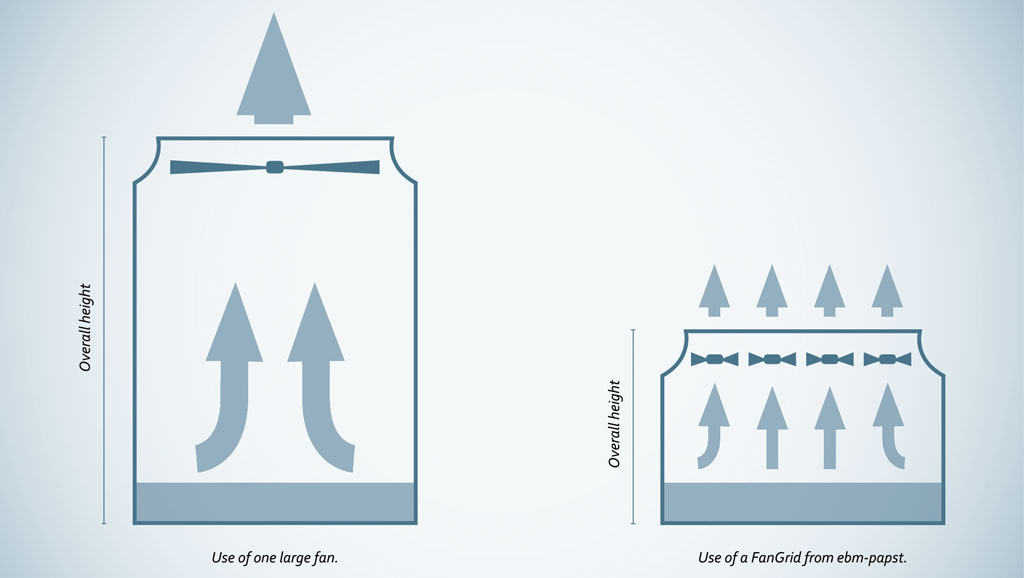

In addition, the corners of the cooling tower do not have uniform through-flow and the towers also end up being very high because to achieve even through-flow, there must be a large space between the fan and the heat exchanger nozzles. The ebm-papst approach includes replacing the large fan with several smaller fans running in parallel operation (a FanGrid), which translates into several benefits in practice.

(Graphic | ebm-papst)

The individual fans can be stacked or arranged in rows to use the available space to maximum advantage (see graphic above). Due to the fans’ small diameters, cooling towers can be built more compactly and depending on the floor space, have a rectangular or square cross-section. Smaller fans are easier to handle than one large fan. The latter benefit makes transport and installation easier, but is also a major advantage when replacing the fans.

EC fans for efficient cooling towers

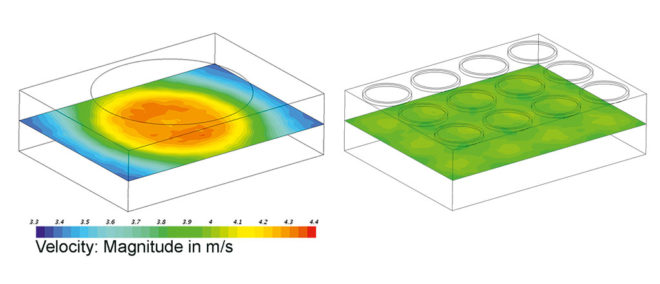

And until a fan is replaced, the cooling tower can operate normally. The speed of the other fans is simply adjusted to maintain constant air performance. During the design process, the relevant redundancy requirements can be taken into account. In addition, the air distribution is much more even when several fans are used (see graphic below). Flow-through is more uniform for all components and disadvantageous dead zone are reduced.

Today, the benefits of a FanGrid can be leveraged in a wide range of applications. Motor and fan specialist ebm-papst provides FanGrid fans for cooling towers in axial or centrifugal design, for example. This means that different requirements for pressure increase and air flow can be satisfied.

Axial fans show their strengths when high air flow and moderate pressure increase are required: for inlet operation, for example. Centrifugal fans are designed for high back pressure and are recommended for pressure operation. A wide range of sizes with a variety of diameters is also available. ebm-papst has a flexible selection tool to help customers find the optimal combination of fans for a wide range of applications: the ebm-papst FanScout.

The flexible selection tool: FanScout

Check out the new FanScout: now in the browser!

Are you looking for the right fan for your application? Then use the new FanScout.

Based on up to five application-specific operating points and the anticipated operating times, this software determines the most efficient FanGrid solution. The amount of installation space available, maximum number of fans required and redundancy requirements can also be taken into account. And there is also an option to determine the life cycle costs of the best combination.

In this way, users receive a reliable, robust cost breakdown upon which they can base their investment and modernization decisions. Sustainability factors can also be taken into account in FanScout. With the sustainability report, CO2 emissions are determined and compared using the automatically calculated energy consumption of the fans.

Save energy and monitor consumption

The driving force behind cooling tower fans are modern EC drives that function highly energy efficiently in full and partial-load operation, are designed for long service lives and feature infinitely variable speed control. This ensures a constant air performance under all conditions. With over 90% efficiency, the motors deliver much more than the values required in efficiency class IE4. The flow machine design also contributes to increased efficiency and quiet operation. Problems due to noise protection regulations are a thing of the past.

An example application shows that the energy savings pay in practice. Instead of one large fan with a diameter of 2,100 mm, four axial fans with a diameter of 910 mm each were installed in a cooling tower to generate the same air flow of 87,040 m³/h at a static pressure of 100 Pa. This enabled power consumption to drop from 7.8 kW to just under 5.3 kW (four times 1.32 kW). In total, the retrofit meant annual energy savings of almost 22,000 kWh for the operator.

For rotation monitoring, the fans can be continuously monitored via an ebm-papst cloud connection. In the process, internal measured values such as speed, motor temperature and vibration values are read out and transmitted to the ebm-papst cloud. Users always have an eye on the FanGrid fans and if necessary, can plan preventive maintenance on their cooling towers.

Successfully tested under extreme conditions

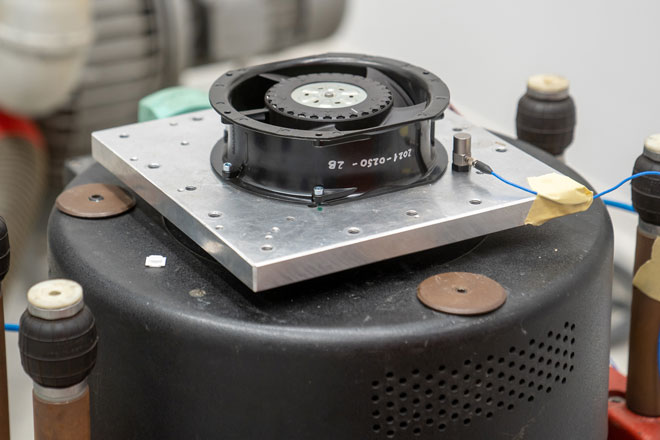

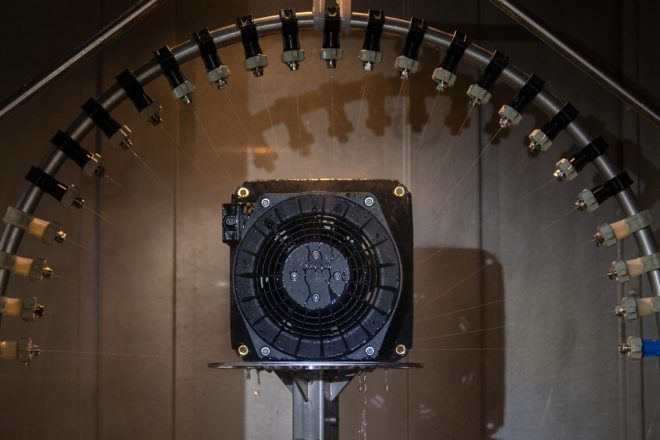

To withstand the high humidity and rapid changes in temperature common for use in cooling towers, the fans have extremely rugged designs. All components are protected by special coatings. The fan series have proven their resistance under extreme test conditions. In the ebm-papst testing center they pass through salt spray tests, vibration and shock tests, proprietary corrosion and moisture tests for qualification. This also includes specially developed tests that take over six months to complete.

Find out how this environmental simulation works in our series about the ebm-papst testing center:

Exclusive insights into all test fields

Learn more about how ebm-papst puts fans to the test in the individual test fields. Each article with exciting insights, videos and pictures!

Thank you for helping me to understand that cooling towers dissipate heat by using fans. I would think that cooling towers are used to cool large buildings since it would be more efficient than a traditional air conditioning unit. A large building would probably have to utilize multiple towers in order to keep the people inside comfortable during the summer.