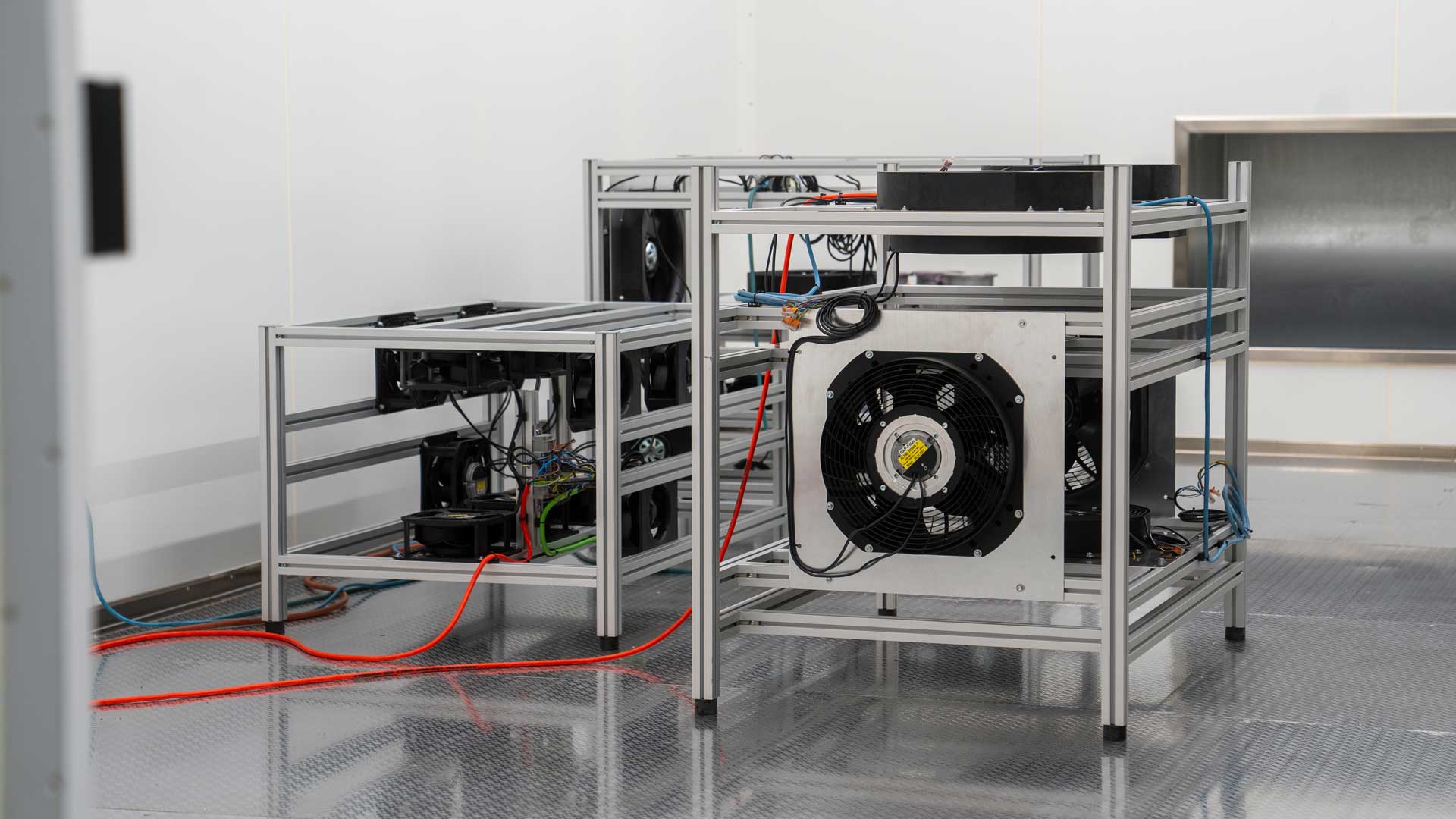

In the testing center in Hollenbach, fans are pushed to their limits and beyond with real-life environmental influences. New products, sizes, and components pass through the test stations in a total of six test bays over an area of approximately 2,500 square meters. In this series, we take a closer look at each of these test bays. The sixth and last one is for accelerated service life tests developed by ebm-papst itself.

Fans need to work reliably for many decades, so their service life must be validated beforehand with all associated loads such as heat or rain. To find out where the critical points in the products lie as quickly as possible, ebm-papst has set up the accelerated service life tests H0, H1, and H2.

Mr. Kemmer, how do you push the fans in the test center to the limit?

They simulate a product’s life cycle in fast motion by combining several types of load. These tests are performed in 40-square-meter chambers at the testing center. H1 and H2 are actually environmental classes introduced by ebm-papst itself.

The accelerated service life tests explained

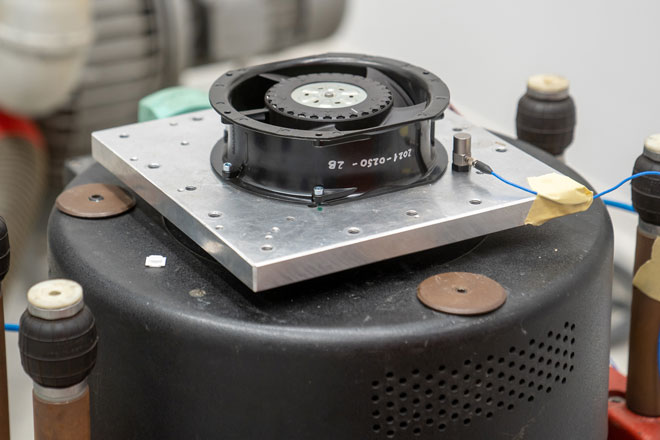

Test H0

A fan in the field is run at an ambient temperature of 20 to 40 degrees Celsius and at 20 to 70 percent of its power, for example. To map this standard load profile quickly, the product is run at maximum power and the maximum permissible ambient temperature for about 6 months in the H0 test.

Test H1

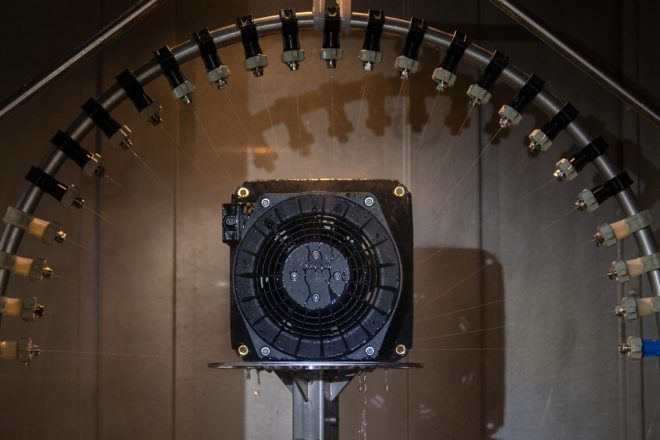

The H1 test is a “temperature change rain test” developed by ebm-papst itself. It is a long-term test that tests the resistance of fans to climatic conditions. In this case, the fan is run for six months and subjected to five alternating temperature cycles per day (900 in total, from -10 to +60 degrees Celsius), as well as condensation.

Test H2

The H2 test is also a “temperature change rain test” which tests the fan’s resistance to climatic conditions over a long period of time. The fan is run for six months and subjected to five alternating temperature cycles per day (900 in total, from -10 to +60 degrees Celsius). However, direct rainfall is added in this case.

The employees carry out visual and functional tests both before and after the long-lasting inspections. For the visual tests, they rely on their intuition and accumulated experience to detect even the smallest damage such as cracks. For the functional tests, the parameters that count are speed, power or temperatures, which are logged in real time during the tests – by IntelliGate gateways from ebm-papst neo.

Evaluate with IntelliGate from ebm-papst neo

Thanks to the gateways, employees can access the logged data at any time from anywhere, as it is automatically backed up in a cloud. It is even possible to automatically check the values of a test for deviations from the specifications and receive corresponding alarm messages. After the end of the test, the data is then stored collectively.

Exclusive insights into all test fields

Learn more about how ebm-papst puts fans to the test in the individual test fields. Each article with exciting insights, videos and pictures!

Leave a comment