In the testing center in Hollenbach, fans are pushed to their limits and beyond with real-life environmental influences. New products, sizes or components pass through the test stations in a total of six test fields over an area of approximately 2,500 square meters. In this series, we take a closer look at each of these test bays. The second focuses on climatic conditions.

Climatic conditions

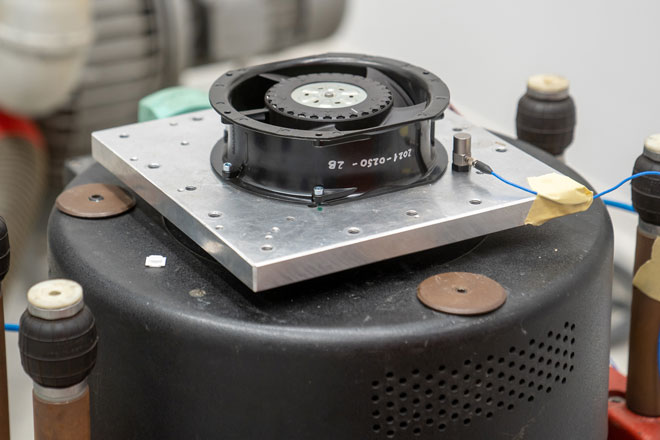

Eugen Schneider checks fans and ventilators in the two climatic chambers in the testing center.

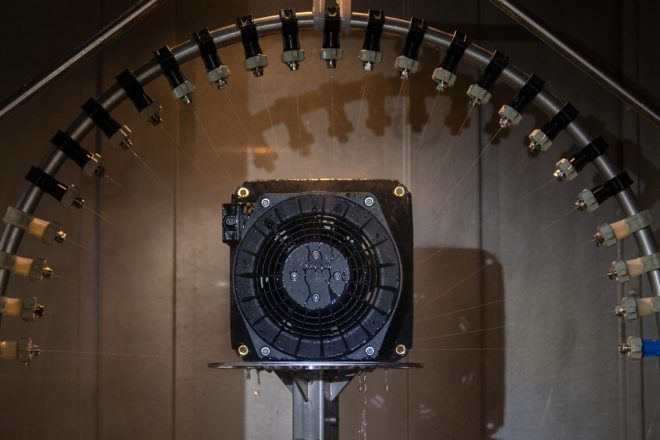

Sudden and rapid temperature changes can affect the service life of the fan, even before it is used at the customer’s premises. This can happen, for example, when transporting it by ship or truck. In a container, for example, sunlight quickly causes the temperature to rise, the package heats up and the temperature drops overnight. In addition, there may be high humidity in the air.

Such temperature loads primarily affect the fan’s material combinations made of metal and plastic. Because they expand differently in heat or pull together in cold conditions, the connections can develop weak points or even come loose. This is why the entire fan is tested in climatic chambers in the climate test bay.

Mr. Kemmer, what is the task of the climatic chambers?

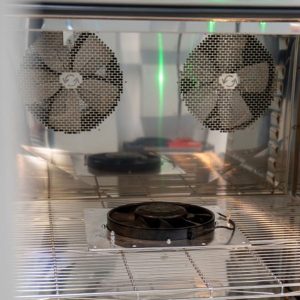

There are two different climatic chambers in the climate test bay. In the first climatic chamber, employees can vary the temperature between -70 and +180 degrees Celsius and, if necessary, also change the humidity of the air to between 10 and 98 percent. The rapid change in temperature is simulated on the test specimen in the climatic shock cabinet.

The cabinet consists of two chambers, which are coupled by an elevator system. In the upper chamber, the test specimen is exposed to a high temperature; in the lower chamber, it is exposed to the cold. The test material – which is what employees in the testing center call the fan – moves from the top to the lower chamber, which involves a temperature increase of up to a hundred degrees Celsius within a few seconds.

In reality, of course, a fan rarely experiences such significant fluctuations. The climatic chambers operate at such high exposures to quickly reveal critical points on the materials. This enables them to be corrected with pinpoint accuracy where required.

Exclusive insights into all test fields

Learn more about how ebm-papst puts fans to the test in the individual test fields. Each article with exciting insights, videos and pictures!

Leave a comment