In the testing center in Hollenbach, fans are pushed to their limits and beyond with real-life environmental influences. New products, sizes or components pass through the test stations in a total of six test fields over an area of approximately 2,500 square meters. In this series, we take a closer look at each of these test bays. The fourth focuses on humidity and moisture.

In the IP protection class test bay, water tests are carried out according to the IP degrees of protection, i.e. standardized tests. The IP degree of protection describes to what degree devices are protected against the ingress of humidity and moisture, for example. In Hollenbach, the employees in the testing center carry out five standard tests: IP X3 to IP X6 and IP X9K.

Water march

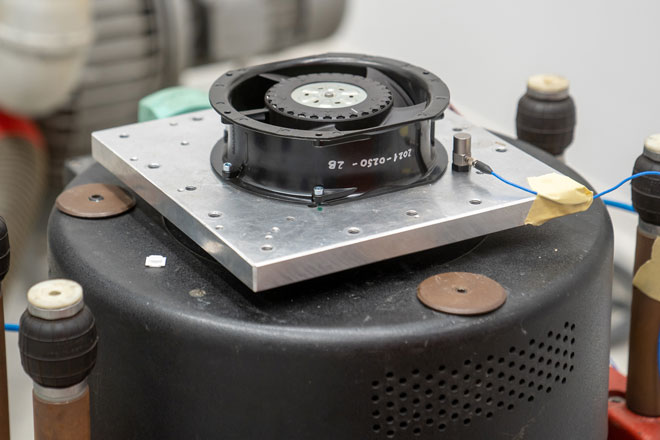

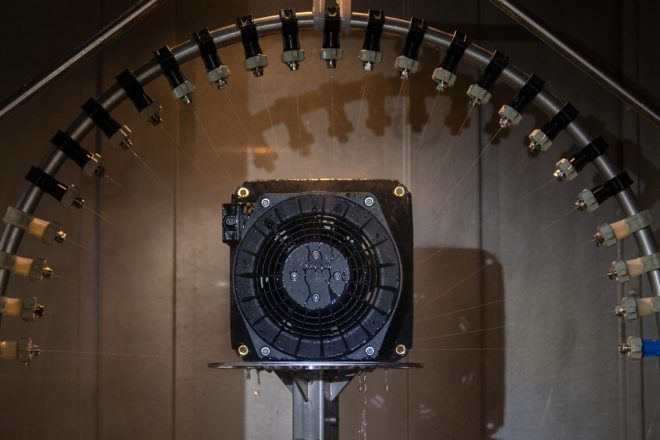

Erich Kemmer and Eugen Schneider at the splash water chamber: This is where the test specimens are water tested as part of the IP protection type tests.

To do this, the test specimens are mounted on a rotating table in a splash water chamber. Depending on the IP degree of protection, water – with a specified quantity, pressure and at certain angles – is directed at the test specimen using spray arches with nozzles or a water jet nozzle. In real life scenarios, fans experience these conditions when there is rain, for example, if they are installed on a roof and exposed to the weather, or by using them in a washing system. This range of different moisture exposures is what is found in the IP protection class water test bay.

IP degree of protection tests in the testing center

IP protection class water

Protection class IP X3:

Sprayed water

IP protection class water

Protection class IP X3

The spray arch floats around the test specimen at a +/- 60 degrees angle for 10 minutes, with 0.07 l/min water per nozzle.

IP protection class water

Protection class IP X4:

Splash water

IP protection class water

Protection class IP X4

The spray arch floats around the test specimen at a +/- 180 degrees angle for 10 minutes, with 0.07 l/min water per nozzle.

IP protection class water

Protection class IP X5:

Water jet

IP protection class water

Protection class IP X5

The water jet sprays the test specimen with 12.5 l/min, for at least 3 minutes.

IP protection class water

Protection class IP X6:

Pressurized water jet

IP protection class water

Protection class IP X6

The water jet sprays the test specimen with 100 l/min of water, for at least 3 minutes.

IP protection class water

Protection class IP X9K:

Flat jet nozzle

IP protection class water

Protection class IP X9K

This test simulates cleaning with a steam jet nozzle: The test specimen rotates on the rotating table, a flat jet nozzle sprays 14-16 l/min water, 30 seconds per position onto the product. The water temperature is also increased to up to 80 degrees.

After each individual protection class test, high voltage and function tests are performed on the fan. If no harmful water has penetrated, the test has been passed.

Exclusive insights into all test fields

Learn more about how ebm-papst puts fans to the test in the individual test fields. Each article with exciting insights, videos and pictures!

Leave a comment