In the testing center in Hollenbach, fans are pushed to their limits and beyond with real-life environmental influences. New products, sizes and components pass through the test stations in a total of six test bays over an area of approximately 2,500 square meters. In this series, we take a closer look at each of these test bays. The fifth one deals specifically with the effects of salt spray.

Fans are also used on the coast or out at sea. The air there is salty and can thus affect the service life of the products. “Salty air affects fans,” explains Erich Kemmer, Group Leader Validation.

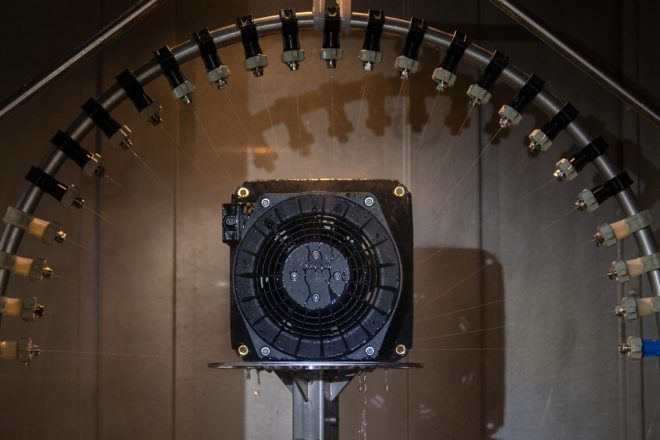

“However, this test bay is not about mapping their use out at sea and the resulting loads. That wouldn’t be easy to do either; after all, the salt content of the air varies and the effect on the fan also depends on factors such as the wind. Our aim is to find out as quickly as possible whether corrosion occurs on the test specimens under the influence of salt spray.”

With the salt chambers, we can quickly find out whether corrosion occurs on the test specimens under the influence of the salt spray.

Erich Kemmer, Group Leader Validation

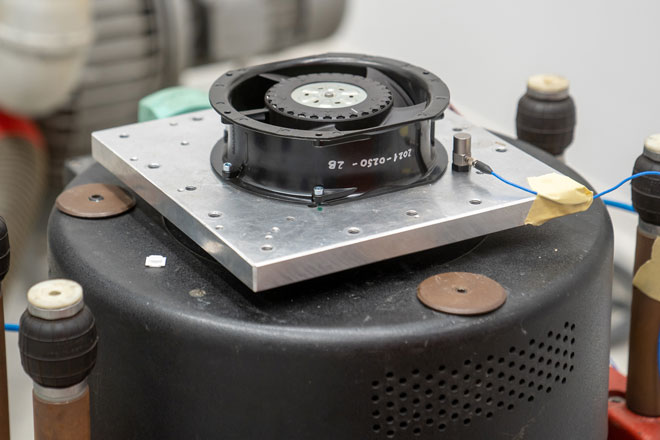

To this end, the test specimens – which can be entire fans or individual components – are exposed to a mist of salty air in closed chambers at the testing center. This atmosphere does not mimic real salty air as closely as possible; instead, it in fact has a significantly higher salt content, which can affect the fan in the real world due to the weather as well as chemical or climatic influences. The test is primarily intended to check the quality of the coatings and welding points. Are they susceptible to corrosion? Are seals infiltrated? Could this allow moisture to penetrate the fan, the motor windings, or the electronics?

Exclusive insights into all test fields

Learn more about how ebm-papst puts fans to the test in the individual test fields. Each article with exciting insights, videos and pictures!

Leave a comment