How many test fields are there in the testing center?

The testing center is approx. 2,500 square meters. How many test fields are there?

- Six

- Twelve

- Four

The solution:

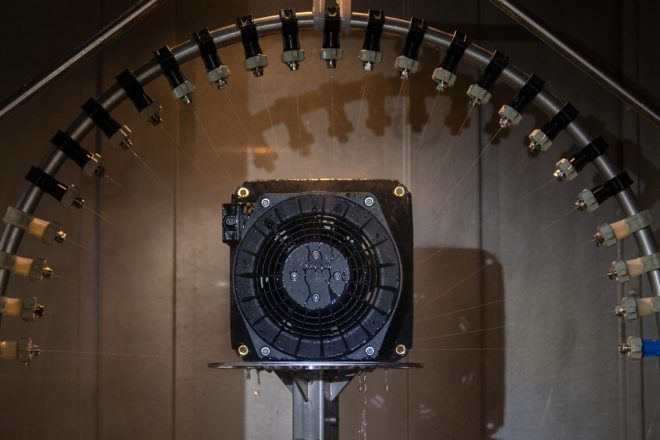

There are a total of six test fields: shock and vibration, climate, impeller strength, spin and cycle test, water IP degree of protection, salt spray, and accelerated service life tests.

Which environmental influences are the fans tested for in the testing center?

All these environmental influences can affect the service life of fans, but which ones have a test field?

- Temperature

- Humidity

- Water

- Ice

- Storm

- Salt spray

- Vibration

- Shock

- Noise

The solution:

Each environmental influence acts on the test specimens individually and also in combination. Heat and cold are tested under the temperature environmental influence in the testing center and do not have their own test.

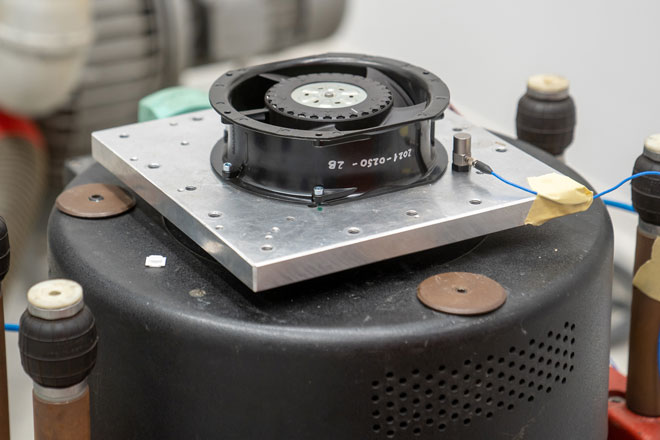

(Photo | Lukas Zwiessele)

What happens if a product is damaged during a test?

Things can and should crack and break in the testing center sometimes – but what happens then?

- It goes back to the developer.

- It goes onto the next test field.

- It is destroyed and a new product undergoes the test again.

The solution:

If a fan or component is damaged during a test, this is noted accordingly and the test specimen is returned to the developer. They then have to find out what is the problem with the product and improve it.

Which components have their own specific test fields?

Different components and materials also have different damage symptoms. The following components therefore also have different test fields:

- Metal impellers

- Nuts

- Plastic impellers

- Wing screws

- Cable harnesses

The solution:

Metal and plastic impellers have different failure patterns. Metal tends to break and plastic flows, meaning it expands. For this reason, the impellers each have their own test field.

We demand everything from our products in the testing center in Hollenbach, in order to discover critical points faster.

Erich Kemmer, Group Leader Validation

When it comes to the climate test field, which temperature range is used in the climatic chamber to test the fans?

Are the temperatures used similar to those that occur in a fan’s real service life or are the loads perhaps even higher?

- 0 to +100 degrees Celsius

- -30 to +120 degrees Celsius

- -70 to +180 degrees Celsius

The solution:

The climatic chambers provide a temperature range of -70 to +180 degrees Celsius. These high loads mean that critical points can be discovered more quickly.

What additional humidity content can the climatic chamber simulate?

There is also a changing humidity in addition to the change in temperature – but how high can this be?

- 0 to 50 percent

- 20 to 90 percent

- 10 to 98 percent

The solution:

In addition to the various temperatures that can be set, the humidity content of the air in the climatic chamber can also be set from 10 to 98.

(Photo | Lukas Zwiessele)

Which tests are specifically used to test the impellers?

Fan impellers rotate around the clock. Which three tests in specific do these components undergo?

- Spin test

- Cycle test

- Climate test

- Impeller strength test

- Salt spray test

The solution:

Impellers are put to the test in the three-part test field of impeller strength, spin, and cycle test.

How long do the accelerated service life tests (H0, H1, and H2) each take?

Temperature changes, rain, ice – this test field really gets down to business. How long could that take?

- Two weeks

- Three months

- Six months

The solution:

Just one of the accelerated service life tests takes six months – during which time the test specimen is really put through its paces.

Exclusive insights into all test fields

Learn more about how ebm-papst puts fans to the test in the individual test fields. Each article with exciting insights, videos and pictures!

Leave a comment