In principle, a heat pump works like a refrigerator, which withdraws heat from the food stored in it and transfers it outside. Air/water heat pumps extract heat from the surrounding air and transfer the heat to the heating system, which warms the living areas or is used to heat water. Fans provide the needed air flow through the unit’s evaporator, with the best results always being achieved when the fans are driven by modern EC motors. They are energy-efficient and very quiet, their speed is smoothly adjustable, and they have long service lives.

Axial or centrifugal fan?

The RadiCal series

Learn more about the new generation of the RadiCal series.

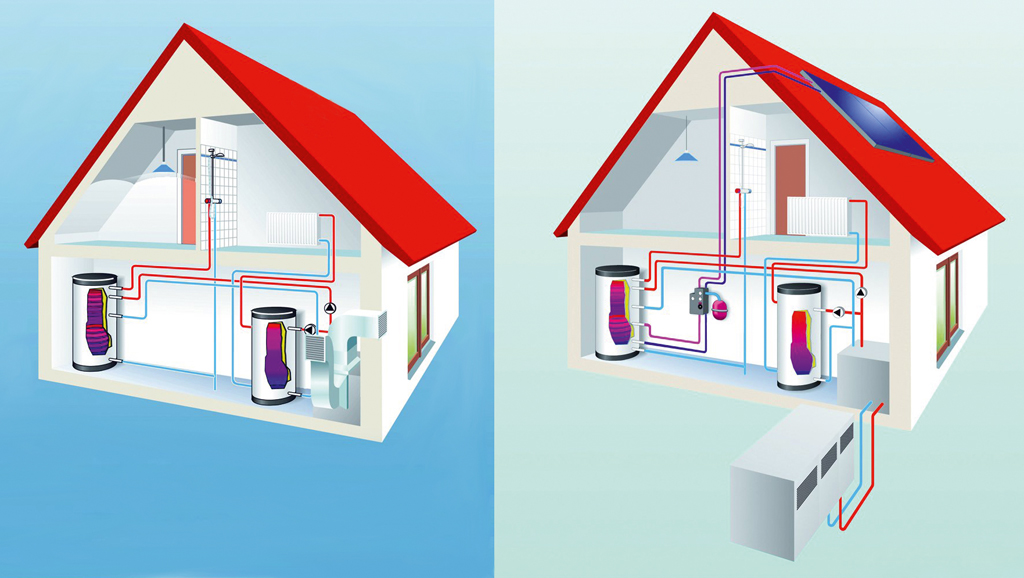

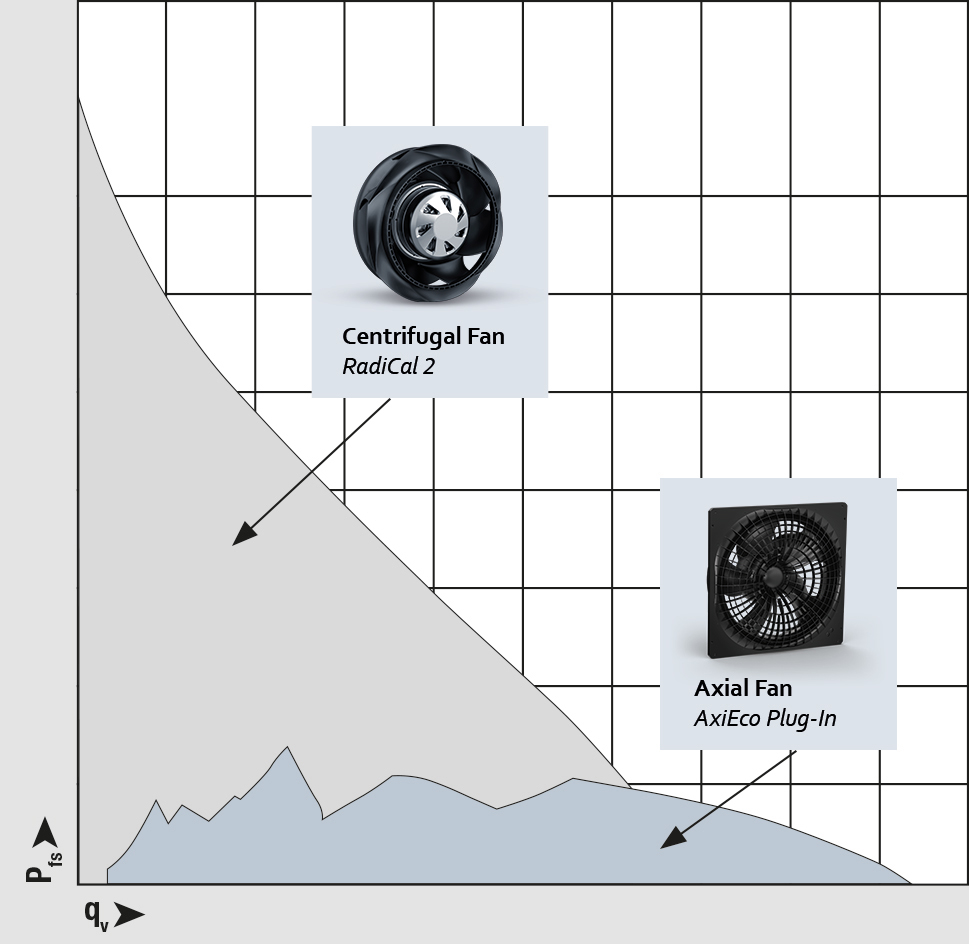

There are two types of air/water heat pump; they are designed for indoor or outdoor installation (Fig. 1a, 1b). The two types place different demands on the fans that are used (Fig. 2). In indoor installations, outdoor air is drawn in through one duct and expelled later through another. Centrifugal fans are effective for this application as their design is suited to higher pressure requirements.

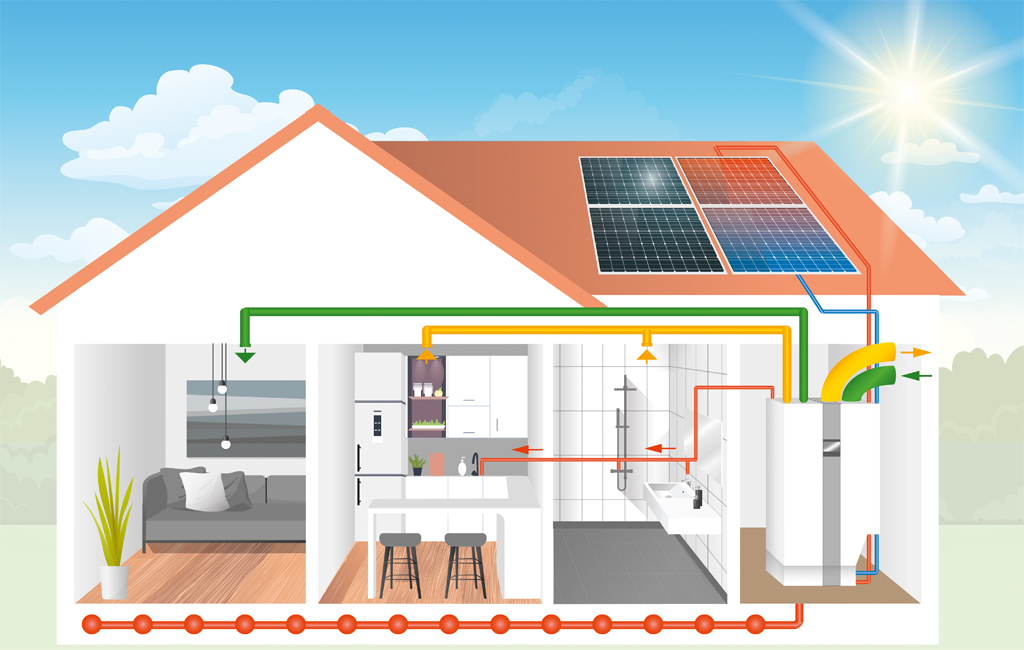

They are very compact, benefiting the air/water heat pumps that are also installed indoors where space is usually limited. This also applies for systems that combine the heat pump and the residential ventilation unit (Fig. 3).

In contrast, space is usually not a problem for outdoor installations, where the evaporator is a separate unit and a refrigerant line leads indoors. These configurations mainly use quiet-running axial fans.

With both axial and centrifugal fans in various sizes, motor and fan specialist ebm-papst offers the right fan solution for every air/water heat pump.

Motor and fan specialist ebm-papst has now developed two new fan series for particularly noise-sensitive outdoor areas: Both are suitable for use with natural and flammable refrigerants and are particularly quiet thanks to their special design, which helps prevent the heat pumps from becoming a disruptive factor and allows them to blend in well with their surroundings. While the AxiEco plug-in is suitable for heat pumps requiring a large pressure reserve for the evaporator, the AxiTone is geared more towards delivering higher air flow at low back pressure when the heat pump design requires this

Axial fan with high pressure reserve

Ice formation particularly affects evaporators when humidity precipitates as ice on the heat exchanger at cold ambient temperatures. This reduces the air routes and the drag, and so too the back pressure. The fans then have to offer significantly greater pressure reserves. This is where the new AxiEco Plug-in comes in (Fig. 4). Studies have shown that its flow technology reduces ice formation and its air flow only reduces very slightly as the pressure increases. This is also an advantage for heat pumps, which heat in winter and cool in summer, as the operating points then vary depending on operation.

The fan, which will be available in the 450 and 500 sizes typical for heat pumps in single- or two-family homes, has also been fitted with an air inlet grille. This FlowGrid, which acts as a rectifier for air flow, drastically reduces noise-generating disturbances in the air flow. This reduces the sound pressure over the entire frequency range, in particular the disruptive blade passing noise, i.e. unpleasant “humming” in the low frequency range.

At the same time, the air inlet grille serves as a motor suspension and, if necessary, the equipment manufacturer can insert heating tape. The new axial fan weighs 30% less than the comparable HyBlade version with steel wall ring. This means that less weight has to be handled during the installation and the compact dimensions often make it possible to optimize the design of the end device. The AxiEco Plug-in fans are supplied as a ready-to-install plug & play solution, including nozzle plate and FlowGrid.

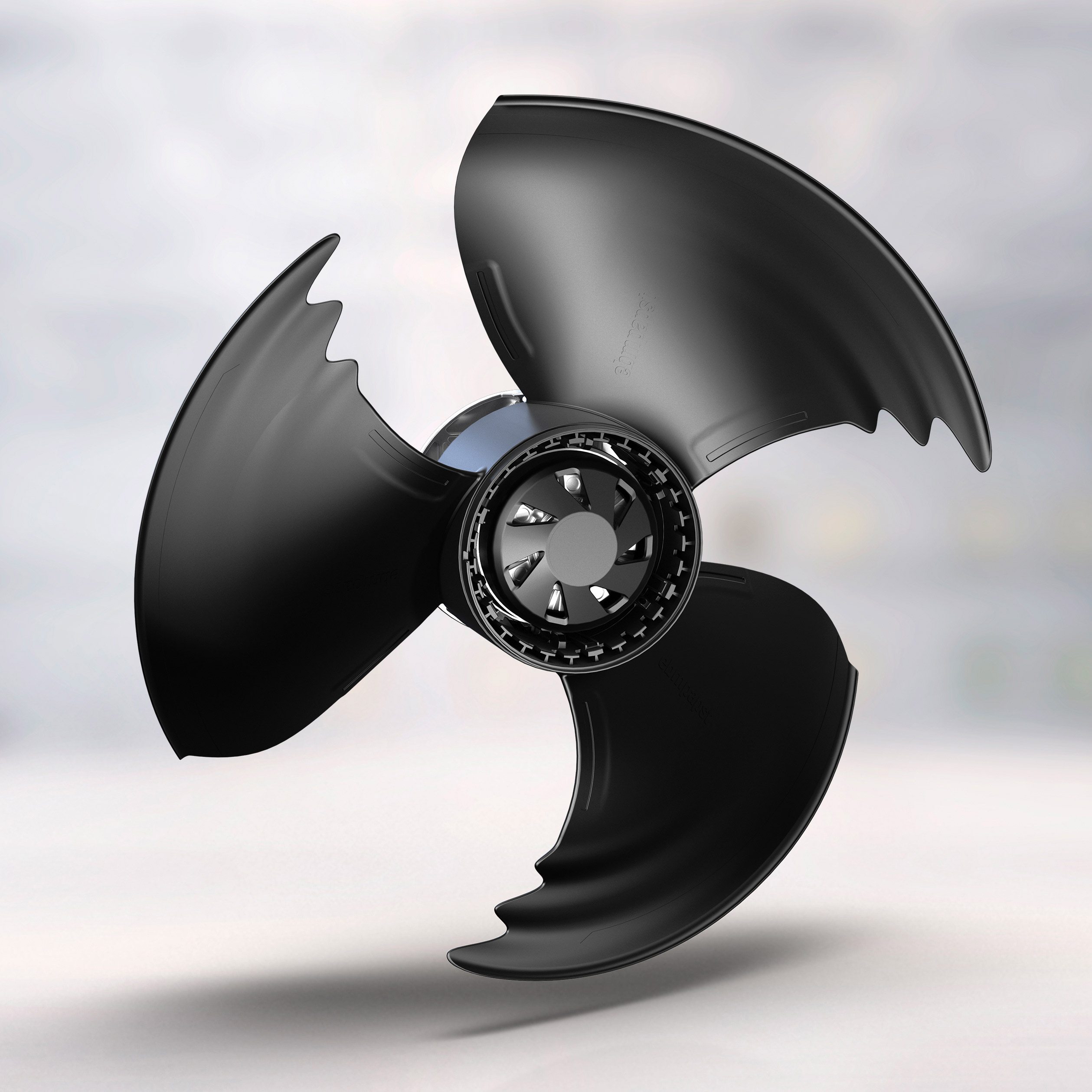

Quiet fan with three blades

For air/water heat pumps, where high back pressure tends to be the exception due to their design, the three-blade AxiTone – initially available in size 450 mm and later in sizes 500 and 630 mm (Fig. 5) – is the obvious choice. Its characteristic curve is flatter, it supplies large volumes of air, and, as the name suggests, it makes very little noise during operation.

The blade geometry plays a key role in both respects, as it has been optimized to aerodynamic criteria. The large area and steep inclination ensure high air flow, and the sickle-like shape reduces turbulence and hence noise generation.

Other new features include the serrations at the front edge of the blade. They also have a positive effect on the noise characteristics, as they minimize the tonal components of noise. Condensers in residential areas, where particular attention must be paid to minimum noise emissions, therefore also benefit from this quiet axial fan. The AxiTone is available as a ready-to-install motor-impeller combination in both airflow directions, i.e., intake or blowing, and optionally with a guard grill and support ring. It is also suitable for applications with flammable refrigerants.

Psychoacoustics – how is a fan supposed to sound?

Psychoacoustics is concerned with describing personal sound perception in relation to measurable noise levels, i.e. it aims to explain why we perceive noises as pleasant or unpleasant. This is something that physical measurements of sound levels in test rigs are unable to address. For example, trumpet music and a construction-site excavator have approximately the same sound power but are perceived psychoacoustically in completely different ways. ebm-papst addressed this matter by setting up a special psychoacoustic laboratory in which noise from fans in various configurations is played back for eight test subjects. Employees question the subjects afterwards to build up a scientifically founded database based on the following psychoacoustic parameters: loudness (unit: sone), sharpness (unit: acum), pitch (unit: mel), roughness (unit: asper) and fluctuation strength (unit: vacil). Other important quantities are tonality and impulsiveness. They can be measured with microphones and compared with comments made by the test subjects. Assessments by the test subjects are analyzed with statistical and psychological methods. The results are used for product development. The ultimate aim is to develop a fan whose operating noise is perceived as pleasant by as many test subjects as possible.

CFD-simulation as a service

Does air have to flow through a heat exchanger as evenly as possible? Is the simulation supposed to detect pressure losses? Does the customer want to perform a general check on the choice of fan? Is the device in which the fan operates supposed to be as quiet as possible? CFD can be used to calculate, visualize and improve the flow conditions in the customer device, or to compare different concepts with one another. The fan’s energy consumption and sound depends on how the housing encourages air flow, whether it is drawn in axially from the front, centrifugally from all sides or on one side. In poor cases, this can double the power consumption or halve the efficiency, and can significantly increase the noise level. CFD helps in understanding the aerodynamic conditions in the device. ebm-papst supports this with its long-standing CFD experience and offers such evaluations and calculations to ensure that the fans operate as efficiently as possible in the application. Even small optimizations to the installation situation can reduce pressure losses, increase efficiency, or minimize running noise.

Additionally, the discussion on fan selection criteria and energy efficiency considerations underscores the importance of informed decision-making in HVAC system design and maintenance. Overall, this article serves as a valuable resource for both professionals and homeowners looking to enhance the efficiency and effectiveness of their heat pump systems.