The Menred Group’s Green Building Industrial Park in Wenzhou City covers an area of over 60,000 square meters. The photovoltaic panels installed in the development generate more than one million kilowatt hours of electrical power per year. As a result, the system saves almost 1,000 metric tons of CO2 per year compared to coal power generation. Low-energy technology for carbon neutrality. In addition to factories and office buildings, the Holiday Campus is located in the climate-neutral industrial park. The building has many uses, including as a hotel for corporate guests and, in line with Menred’s mission – innovation for carbon neutrality in buildings – it is a ultra-low energy building.

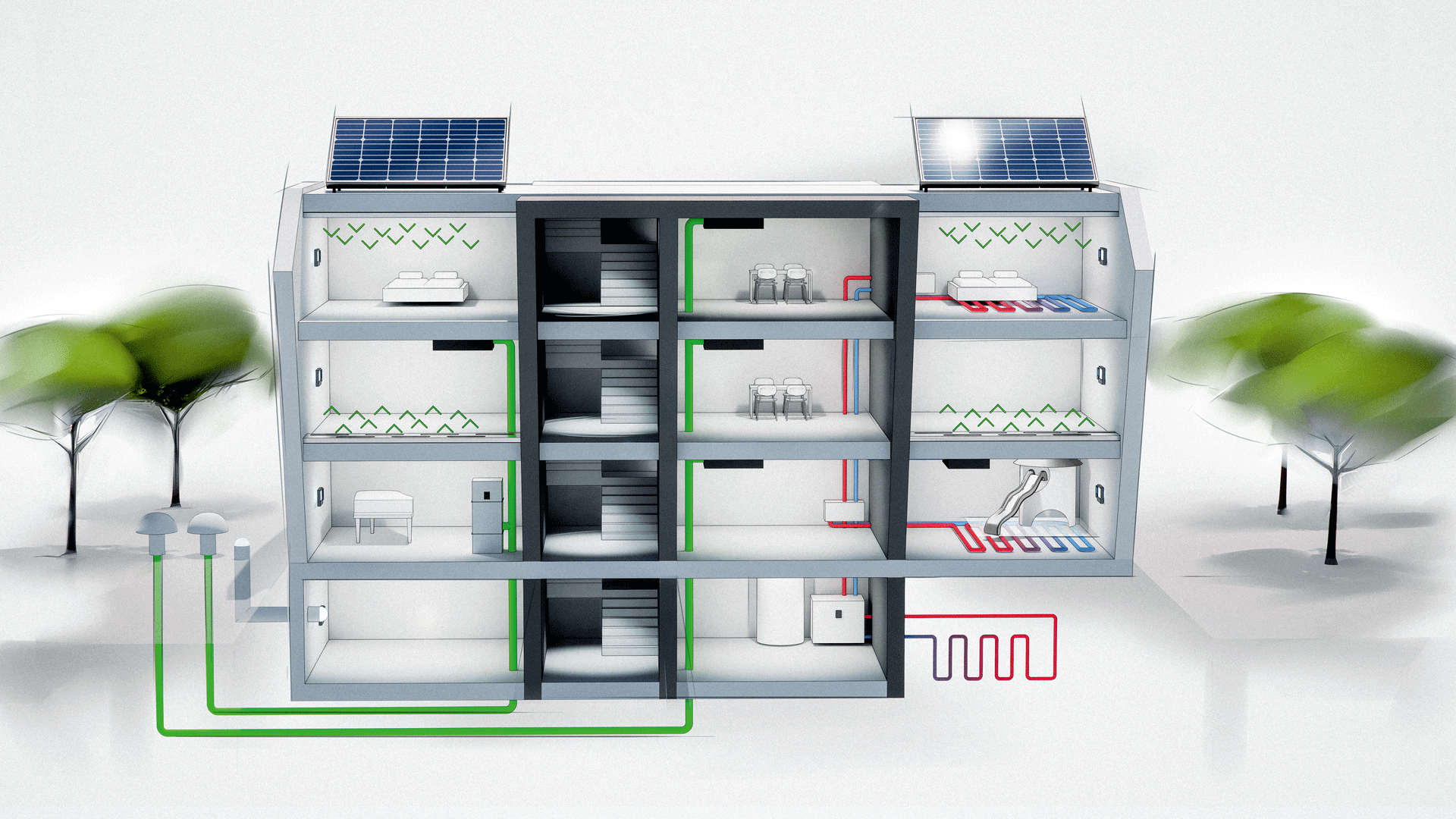

Buildings like this are an important step towards carbon neutrality: They consume almost no energy and emit very small amounts of CO2 during their lifetime. Particularly economical technologies such as heat pumps and air handling units with heat recovery are therefore used for heating, cooling and ventilation. The little energy required is ideally generated by the building itself, for example using solar heating for hot water and photovoltaics on the roof. As a result, the building’s total energy requirements and CO2 emissions are virtually zero.

(Photo | Una Zhu)

Sustainable strategy since 1995

Since it was founded in 1995, the Menred Group has been manufacturing environmentally friendly products for buildings like these in the areas of air conditioning, heating, fresh air, water treatment and smart homes. In fact they have already been working with ebm-papst on residential ventilation for ten years: “Systems like ventilation systems run 24 hours, 365 days a year. Efficiency and reliability are our customers’ most important concerns, so the fans have to meet the highest standards – hence our long-standing collaboration with ebm-papst,” explains Chen Wei, General Manager of Zhejiang MENRED Environmental Technology Co., Ltd. The company’s sustainable technologies are turning new buildings around the world into ultra-low energy buildings, while existing buildings can also be retrofitted for energy efficiency.

“Ventilation systems run 24 hours, 365 days a year. Efficiency and reliability are our customers’ most important concerns, so the fans have to meet the highest standards.”

Chen Wei, General Manager at Menred

Planning for the Holiday Campus began in 2012, and it was completed in 2017. The building houses many different areas under one roof: rooms for guests, lounges and meeting rooms, a playroom and adventure room for children. Each room has different climate and ventilation requirements, but must offer comfort and a pleasant environment for users at all times. How can this be reconciled with the ultra-low-energy standard? Where can the most energy and CO2 be saved?

From previous building experience, the planning team knew that ventilation and air-conditioning systems in their region account for the largest share of energy requirements, at around 70 percent – so the potential for savings was particularly high. On the other hand, the site was very dynamic: a changing number of hotel guests, at sometimes a fully occupied playroom with children romping around or an important business meeting with customers. The result was a wide variety of rapidly changing requirements for heating, ventilation, dehumidification and air purification.

Mix of fans for efficiency

The planning team made a decision: A total of 13 fans, including several different models, were to be used in the Holiday Campus – hand-picked to best suit each floor or room. Three aspects were crucial to Menred in the selection process: energy savings, comfort for residents (meaning a minimum noise level), and the possibility of adjusting the fan speed as needed. The fans had to be controllable because the Holiday Campus has a smart building management system, a MiBEE smart home system that coordinates systems such as air conditioning, ventilation and underfloor heating in real time. Sensors measure the CO2 and moisture content in the air, among other things. Based on these measurements, the systems ensure optimum air quality to guarantee the health and well-being of the people in the rooms.

The music room on the second floor, for example, is usually very busy, which is why Menred installed a ceiling ventilation system there with connected temperature control. Depending on the number of people in the room, the system cools or heats it accordingly. The system contains four centrifugal blowers that draw in and distribute air efficiently and with minimal noise. An integrated heat pump for heating and ventilation.

How the Holiday Campus heats and ventilates

With innovation to the CO2-neutral building

On the third floor of the Holiday Campus, Menred installed an innovative solution: an integrated heat pump environment control unit, or “IEU,” that combines air conditioning, purification and dehumidification in a single device. Inside, there are two centrifugal blowers and one forward-curved motor-impeller per unit. “The combination of these fans results in energy recovery at 70 percent in cooling mode and 78 percent in heating mode. This exceeds the technical standards for ultra-low energy buildings and is a new, environmentally friendly solution for residential buildings,” explains Chen Wei. The annual energy consumption of the fresh air unit in the Holiday Campus is only 15 kWh/m2, which is below the standard value for ultra-low energy building.

Of course, the energy consumption of the entire Campus is also measured and monitored at all times. The Menred team can not only see the current energy consumption and operating status on the control panel, but also draw conclusions for the future. Where can even more energy or CO2 be saved? Not only in the Holiday Campus, but in all buildings that are equipped with their efficient technology.

Leave a comment