The demands placed on the components installed in heat pumps are high, with durability, low noise, robustness and efficiency at the forefront. Although the compressor requires the largest amount of energy of the individual components, the fans should also be scrutinized carefully when considering efficiency. Various aerodynamic adjustments, such as an integrated diffuser and winglets, can further increase efficiency while simultaneously reducing noise.

Given the high efficiencies, the use of state-of-the-art EC technology in the fan’s motor has become a no-brainer, and also allows great flexibility thanks to individual speed adjustment. Development is continuing at a steady pace. Motor and fan specialist ebm-papst, which offers both centrifugal and axial fans in various designs for air/water heat pumps operating indoors or outdoors, has now developed two new fan series for particularly noise-sensitive outdoor areas.

Both are suitable for use with natural and flammable refrigerants and are particularly quiet thanks to their special design, which helps prevent the heat pumps from becoming a disruptive factor and allows them to blend in well with their surroundings. While the AxiEco plug-in is suitable for heat pumps requiring a large pressure reserve for the evaporator, the AxiTone is geared more towards delivering higher air flow at low back pressure when the heat pump design requires this.

Axial fan with high pressure reserve

Ice formation particularly affects evaporators when humidity precipitates as ice on the heat exchanger at cold ambient temperatures. This reduces the air routes and the drag, and so too the back pressure. The fans then have to offer significantly greater pressure reserves. This is where the new AxiEco Plug-in comes in (Fig. 2). Studies have shown that its flow technology reduces ice formation and its air flow only reduces very slightly as the pressure increases. This is also an advantage for heat pumps, which heat in winter and cool in summer, as the operating points then vary depending on operation.

The fan, which is available from summer 2023 in sizes 450, 500 and 630, typical of heat pumps for single- or two-family homes, has also been fitted with an air inlet grille. This FlowGrid, which acts as a rectifier for air flow, drastically reduces noise-generating disturbances in the air flow. This reduces the sound pressure over the entire frequency range, in particular the disruptive blade passing noise, i.e. unpleasant “humming” in the low frequency range (Fig. 3).

At the same time, the air inlet grille serves as a motor suspension and, if necessary, the equipment manufacturer can insert heating tape. The new axial fan weighs 30% less than the comparable HyBlade version with steel wall ring. This means that less weight has to be handled during the installation and the compact dimensions often make it possible to optimize the design of the end device. The AxiEco Plug-in fans are supplied as a ready-to-install plug & play solution, including nozzle plate and FlowGrid.

Quiet fan with three blades

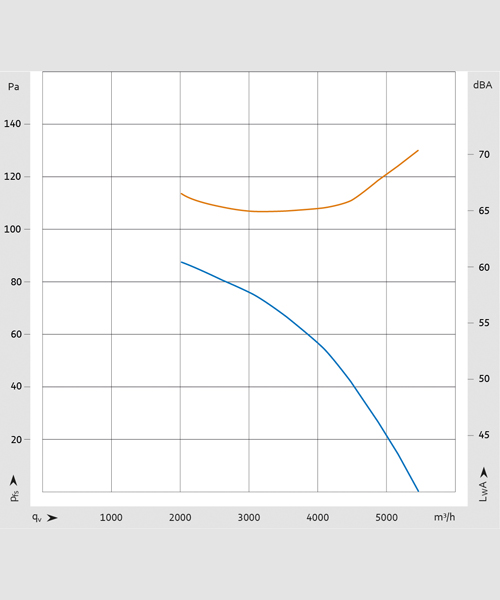

For air/water heat pumps, where high back pressure tends to be the exception due to their design, the three-blade AxiTone – initially available in size 450 mm and later in sizes 500 and 630 mm (Fig. 4) – is the obvious choice. Its characteristic curve is flatter, it supplies large volumes of air, and, as the name suggests, it makes very little noise during operation (Fig. 5).

The blade geometry plays a key role in both respects, as it has been optimized to aerodynamic criteria. The large area and steep inclination ensure high air flow, and the sickle-like shape reduces turbulence and hence noise generation.

Other new features include the serrations at the front edge of the blade. They also have a positive effect on the noise characteristics, as they minimize the tonal components of noise. Condensers in residential areas, where particular attention must be paid to minimum noise emissions, therefore also benefit from this quiet axial fan. The AxiTone is available as a ready-to-install motor-impeller combination in both airflow directions, i.e., intake or blowing, and optionally with a guard grill and support ring. It is also suitable for applications with flammable refrigerants.

Inverter electronics for efficient and low-noise compressor drives

Meanwhile, ebm-papst is not only focusing on offering efficient and quiet fans. Based on many years of experience with EC motors, their commutation electronics, and heat pump applications, the company has now developed inverter electronics that are suitable, among other things, for speed-controlled permanent magnet synchronous machines (PSM), as typically used in compressors (Fig. 6). The new electronics, the samples of which will be available from Q3/2023 and which will be available with output powers of up to 3.5 kW, 7.5 kW and 12 kW, offer several advantages here.

The ebm-papst commutation method, which has been optimized over decades, considerably reduces noise development; at the same time, efficiency is increased. For example, in a heat pump with a 7.5 kW compressor drive, the COP value (Coefficient of Performance) could be increased by 3.5 %. For users, this means an annual saving of 70 euros at an assumed electricity price of 35 cents per kilowatt hour. Depending on the variant, the controls also “detect” whether they are operated in one or three phases, and switch over automatically depending on the type of voltage available in the heat pump. The electronics are also flexible in terms of their cooling. Thanks to their modular design, it is possible to use water or air cooling, or use a cold plate for cooling.

The active three-phase PFC level integrated into the inverter electronics (power factor correction filter) ensures good EMC properties. No additional measures are required to comply with the standards with regard to current harmonics. Given that, depending on the size of the heat pump, conventional expansion valve assemblies can easily weigh up to 20 kg, the weight saving and the reduced wiring effort required by active PFC are considerable.

The low weight of the heat pump simplifies its entire handling, from production to transport and installation by the end user. As a competent partner for heat pump manufacturers, ebm-papst is already planning the next steps to become a system provider. In the future, further components will be integrated into the inverter electronics, for example commutation for the fan drive and the control of a heating rod.

Learn more:

Sustainable energy supply with heat pumps

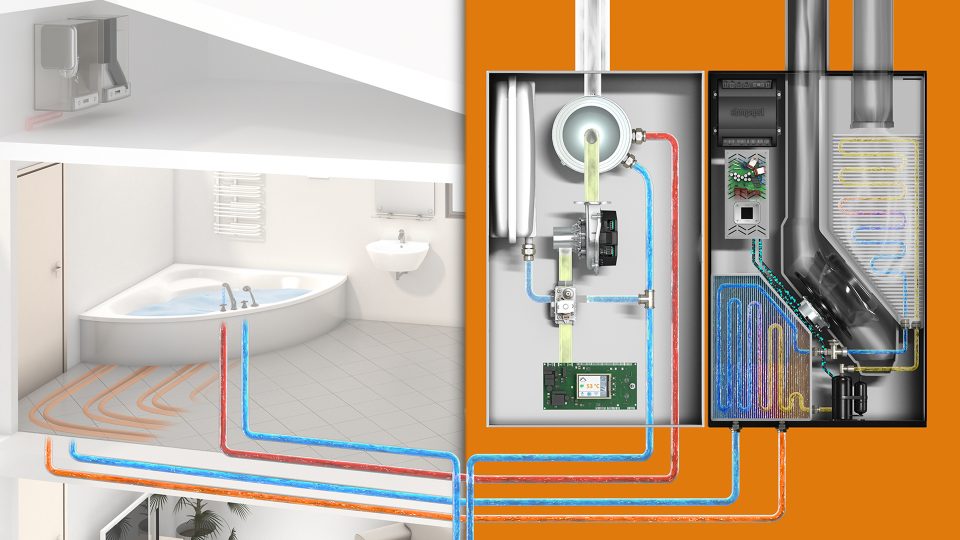

ebm-papst offers efficient and quiet products suitable for indoor, outdoor or hybrid heat pump applications.

Leave a comment