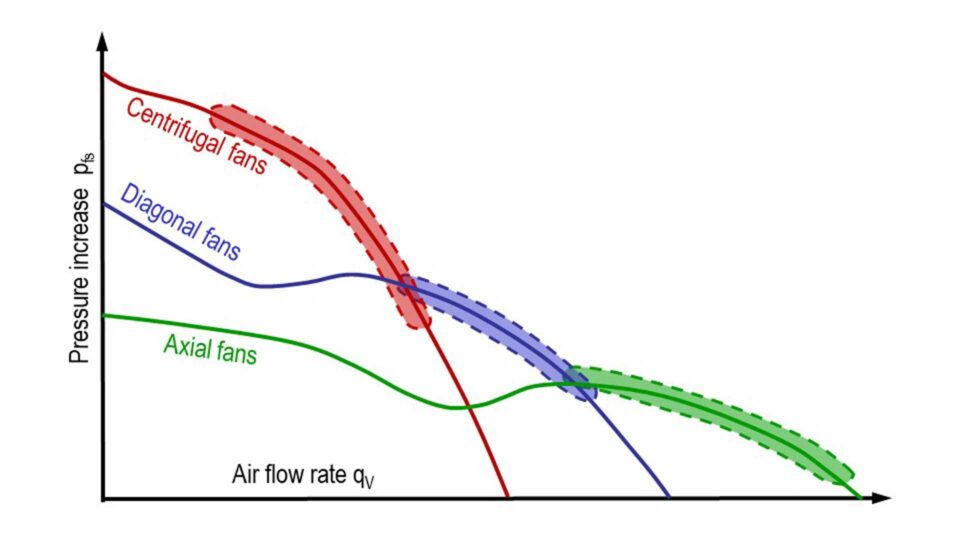

Moving air and creating pressure at best efficiency and with least noise emissions – this is one way to describe the objective of fans. For many applications, they are the best option also because they create a continuous flow, have small space requirements and have only few moving parts. To understand which fan design, centrifugal, axial or mixed, is the best for a specific application, one needs to look at the basic mechanism of fan operation.

Pressure determines which fan fits

In principle, the fan blades of an axial-flow fan deflect the airflow from an axial inflow direction into a helical flow pattern, thereby increasing the (total) pressure across the rotor. To get higher pressure, larger flow angles to the rotating blades are required. However, this principle has natural limits. When the relative flow angle becomes too large, the aerodynamics become less efficient and the detached flow creates increasing noise.

Axial fans

Diagonal fans

Centrifugal fans

In cases where more pressure rise is required, centrifugal forces are used in addition to the blade aerodynamics. Since every fan is a rotating system, the air is always exposed to centrifugal forces. Beyond their best operation point, the flow in axial fans develops a strong centrifugal component, while large portions of the flow path are aerodynamically blocked due to recirculating air. Effectively, the fan operates like a smaller but poorly designed centrifugal fan in this regime.

For those applications, a dedicated centrifugal design is the best choice. In centrifugal fans, centrifugal forces contribute significantly to the overall pressure build-up, in some cases they are the dominant mechanism. Axial fans are best applied to cases where a fairly small pressure rise and large flow rates are required, while centrifugal fans are able to deliver higher pressure together with smaller flow rates for similar external dimensions and speeds.

Optimizing fans with CFD

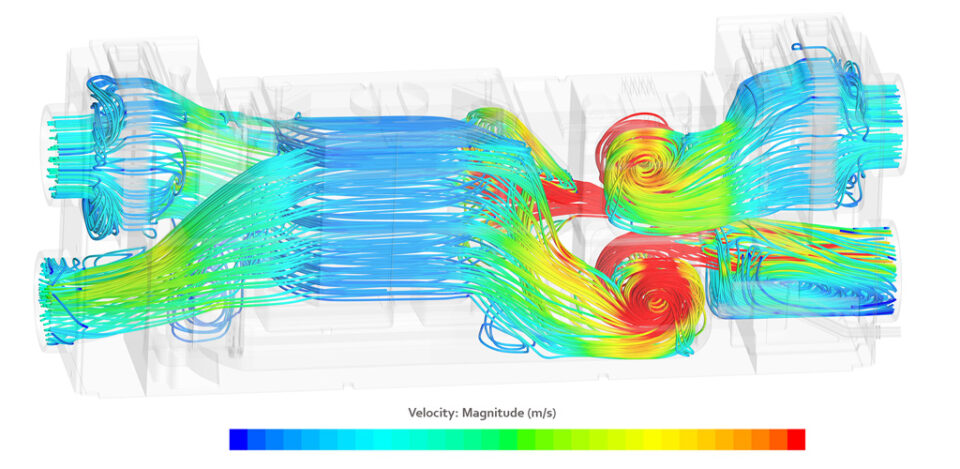

With these basic considerations the actual design can be started. In the past, fans were designed mainly experimentally and a powerful experience base has been established over the years. Today, computational fluid dynamics (CFD) methods are applied to the aerodynamic design process. CFD is used in all kinds of systems where heat and mass transfer is important, for entirely new fans as well as for optimising components like blades or blade-tips. In principle, the aerodynamicist can design a new fan without prior knowledge of the fan type because the CFD method represents a comprehensive mathematical flow model. It is often easier to perform so-called numerical experiments than conducting an experimental campaign, especially since the CFD results allow for very detailed analyses of the flow field.

With CFD, blade performance, loss and noise mechanisms or the interaction of the flow with walls can be understood and improved for every operating point of interest. In times where high efficiency and cost-effective solutions are key drivers, the aerodynamicist tries to squeeze out every possible percent of the available design space. The curved and twisted blades of modern fans or the specific blade tips are examples of such efforts. With state-of-the art design tools it is possible to design the fan for a specific application rather than trying to tailor an existing fan to a new application.

Together with the success of CFD, the focus of the experiments has changed. From being a basic design method to a necessary verification and validation method: on one hand, of the overall performance and on the other hand to verify or dismiss the impact of features like guide vanes or downstream diffusers.

Leave a comment