At motor and fan manufacturer ebm-papst, advanced numerical simulation tools for calculating fluid mechanics are part of everyday development. For many years, the company’s engineers have been working on developing their fans using powerful CFD tools, not only for optimizing complex impeller geometries, but also for motor or electronics cooling concepts or in the context of acoustic testing for noise characteristics. Customers can also benefit from this extensive know-how if they seek support in the aerodynamic development of their own end devices in which ebm-papst fans are to be used.

RadiCal 2: High air flow and quiet operation

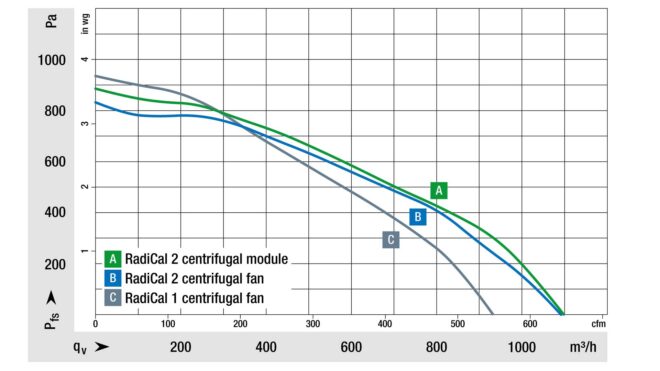

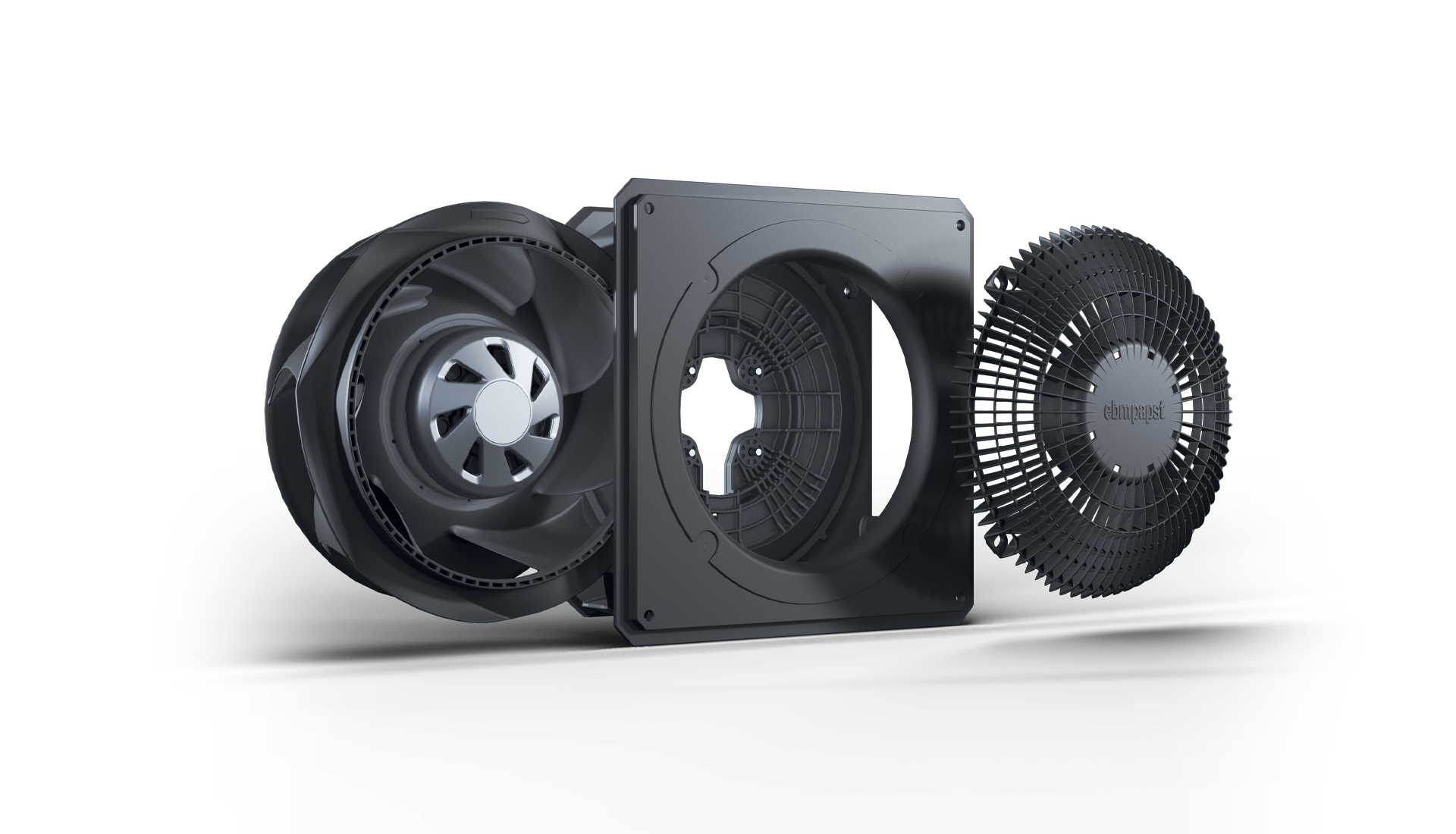

The RadiCal 2 series shows how aerodynamic optimizations of this kind have an impact in practice. The compact centrifugal fans have been designed to deliver high air flows at low back pressure while operating as efficiently and quietly as possible (Fig. 1). Several design details contribute to this, making it possible to achieve a ‘wound’ blade geometry that helps significantly increase efficiency and reduce noise. Not only the blade shape, but also the profile of the inlet and outlet edges has been revised. This improves the flow behavior while at the same time increasing the strength of the fan impeller, which is made of resistant plastic.

The wavy cover plate also improves the aerodynamic characteristics and therefore air performance. With the centrifugal module, i.e. the housing box, the inclined struts further increase the air performance. The axial height of the struts is selected to fill the backflow areas in the best possible way. There is also an enlarged intake diameter, which ensures a greater air flow rate through the impeller.

The optimized FlowGrid air inlet grille also helps to prevent noise. Compared to the earlier series version, both the intake side disturbance and the fan itself is quieter, by at least between 1 and 3 dB(A). As the rotor area had a major impact on noise, the air inlet grille was also given a cap over the area of the motor. This enables the disruptive blade passing noise in the lower frequency range in particular to be significantly reduced. With regard to the environmental factor of “noise”, the fans therefore meet the strictest requirements.

Air guide moduls for greater efficiency

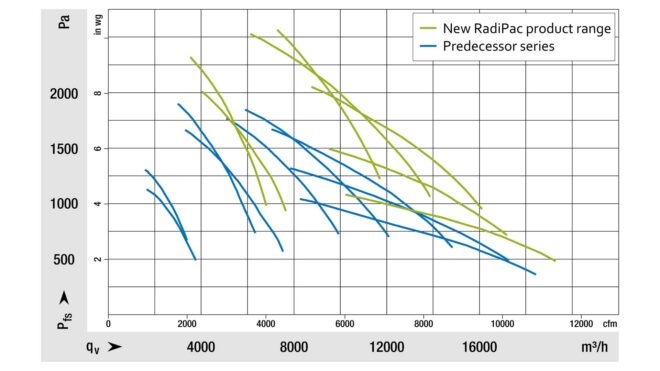

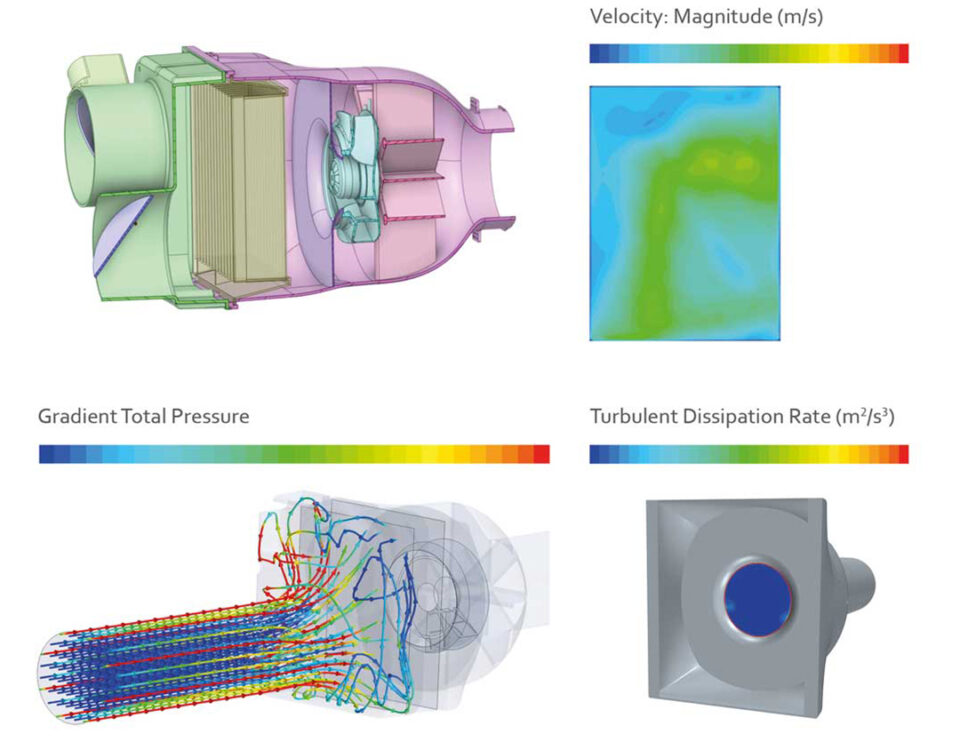

The centrifugal fans in the RadiPac product range were designed and engineered especially for use in air conditioning and ambient air devices and have been constantly improved over the past few years. Higher speeds ensure greater air flow and higher pressures, meaning that even applications with more than 2000 Pa static pressure increase can be covered. (Fig. 2) In addition, noise generation has decreased further; depending on the operating point, the noise level is reduced by between 3 and 7 dB(A) compared to the predecessor series.

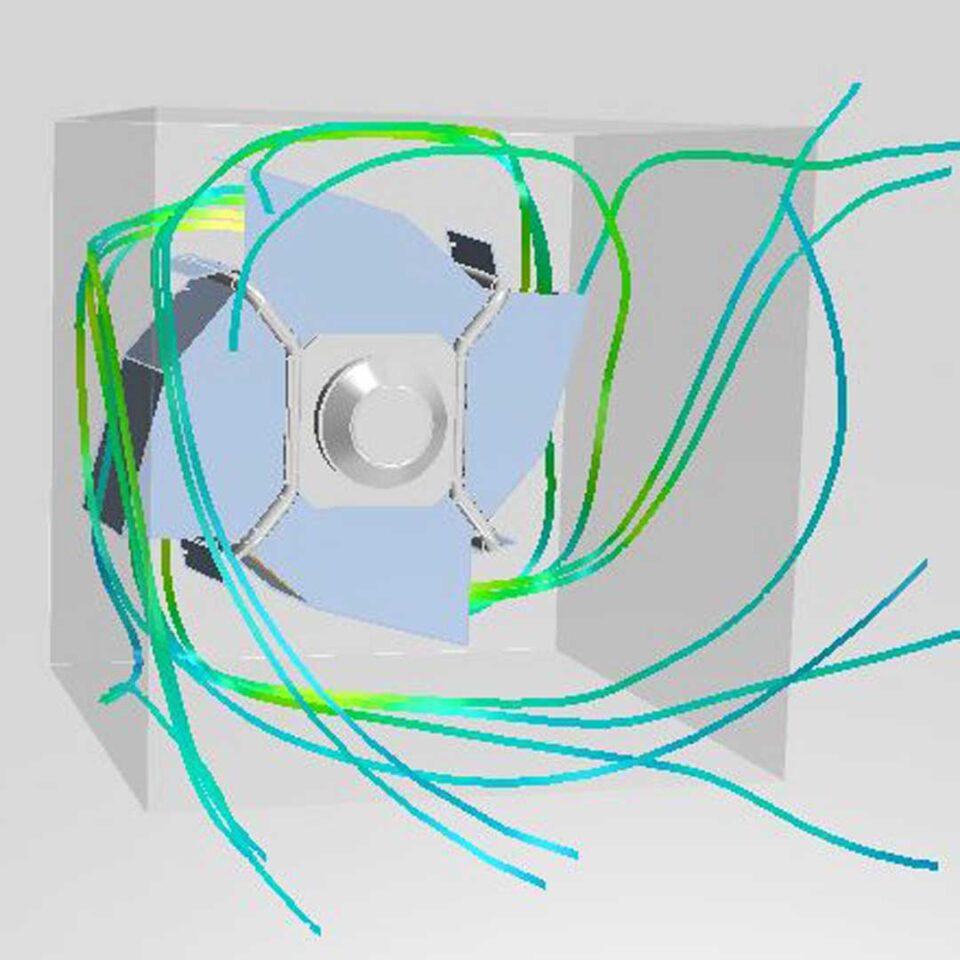

Special air guide modules increase the efficiency again by up to five percent (Fig. 3). This is achieved by reducing the outlet losses. For this purpose, ebm-papst has developed a housing for the RadiPac, consisting of four segments. The module segments are made of galvanized sheet steel and have an aerodynamic shape. This special shape slows down the flow, which reduces the dynamic pressure component and increases the usable static pressure component (Fig. 4). At the same operating point, the fans can run at a lower speed, which in turn has a lower energy consumption and lower noise emissions. The RadiPac C Perform has exactly the same mounting hole pattern as the industry standard, making it easy to change over.

With CFD simulation for optimum fan use

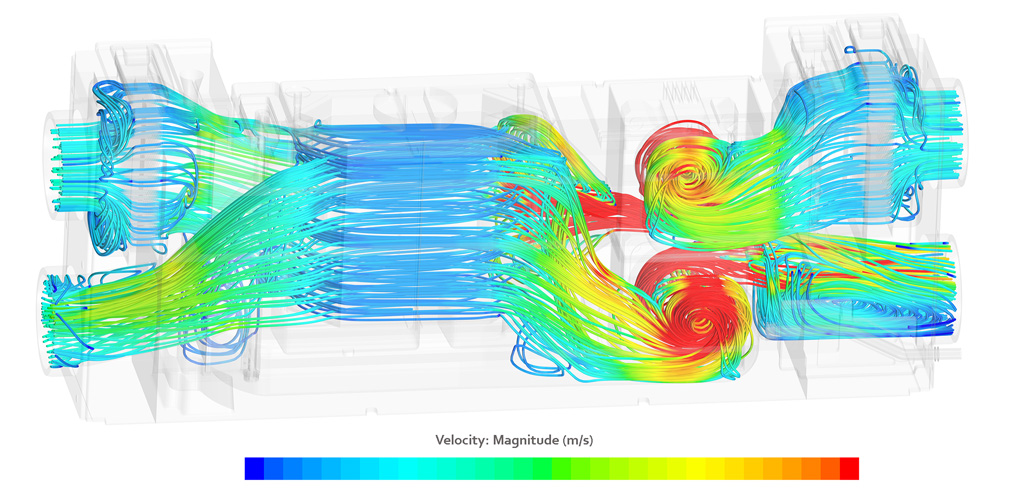

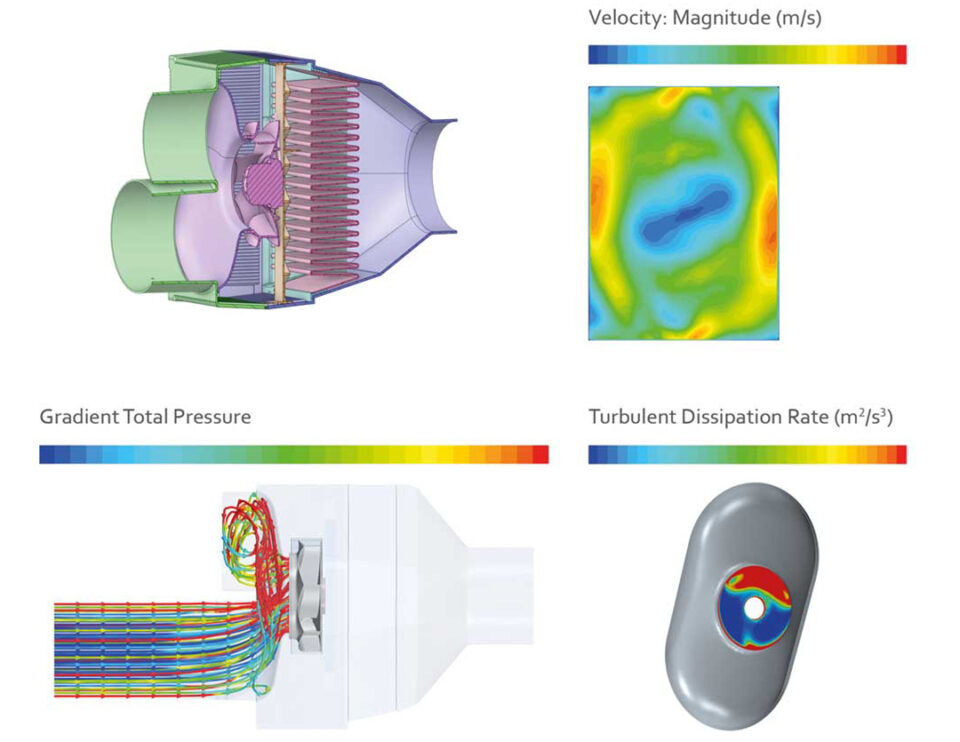

To ensure that the fans really play out their strengths, unfavorable interactions cannot occur after installation in ventilation and air conditioning units. That is why it is advisable to simulate the installation situation for aerodynamics in the early development phases of a customer device. The fan’s energy consumption and sound depends on how the housing encourages air flow, whether it is drawn in axially from the front, centrifugally from all sides or on one side. In poor cases, this can double the power consumption or halve the efficiency, and can significantly increase the noise level. CFD helps in understanding the aerodynamic conditions in the device (Fig. 5).

Before the simulation begins, the objective should first be defined and a few questions answered. Does air have to flow through a heat exchanger as evenly as possible? Is the simulation supposed to detect pressure losses? Does the customer want to perform a general check on the choice of fan? Is the device in which the fan operates supposed to be as quiet as possible? Once the goal has been clarified, the 3D CAD data and the expected operating point (pressure, air flow, speed) of the fan provide the basis for simulation.

In addition, there are also characteristic curves from the filters, heat exchangers or guard grills installed in the device, for example. The data are cleared up and unnecessary details are removed (cleaning). Then the simulation is prepared in a preprocessing phase, meaning that certain boundary conditions are specified and the geometries are networked. The grid structure divides the space that the air passes through into many individual cells, which form the basis of the mathematical calculation. The simulations then run on high-performance computers.

Practical examples: Exploiting potential for optimization

Using the simulation results, the engineers then estimate the potential for optimization and develop concrete suggestions for improvement. For example, a customer developed an air purification device in which the fan was to be used for pushing air out. However, the simulation showed significant turbulence (Fig. 6), which increased the power consumption at the operating point. Using the fan to draw air in, i.e. changing its installation position, proved to be helpful here. The air flow is now very uniform, the power consumption is decreased and there is also a positive effect on operating noise. With an air conditioner for ceiling mounting, the simulation proved that it is advantageous to use a centrifugal fan instead of the usual axial fan.

This was initially counterintuitive, as the operating point of the device indicated that an axial panel fan would be the best choice. However, switching to a large centrifugal fan made an air duct design according to the centrifugal impeller design possible, which meant that no additional deflection was required. This was reflected in a power saving of over 70% with a reduction in sound power level by 20 dB(A). The extent of the pressure losses caused by the deflection of the air towards the side outlet was previously always severely underestimated.

Find and utilise potential with CFD

Before

After

Fig 6: In an air purification unit, the air flow could be significantly improved by changing the fan installation position. The power consumption dropped and the device operates more quietly. (Graphic | ebm-papst)

Another example: Using simulation result once again, the efficiency of a heat pump could be significantly improved. Thanks to geometric changes, the pressure losses in the device fell by a total of 17 percent. The individual sub-areas in the device were assessed separately and the product design was adapted accordingly. The user has also benefited from the options offered by CFD simulation.

These examples show that it is worthwhile for end device manufacturers to rely on numerical flow simulation and to apply these at an early stage of development to avoid subsequent revision costs. ebm-papst supports this with its long-standing CFD experience and offers such evaluations and calculations to ensure that the fans operate as efficiently as possible in the application. Even small optimizations to the installation situation can reduce pressure losses, increase efficiency, or minimize running noise.

Centrifugal fans with forward and backward-curved blades

Centrifugal fans from ebm-papst are available with forward and backward-curved blades. The quiet-running centrifugal fans with forward-curved blades are also supplied with a scroll housing. The centrifugal fans with backward-curved blades are designed as freewheel fans and do not require a scroll housing. In the case of centrifugal fans with external rotor motors, the motor is positioned in the impeller, ensuring not just optimum cooling of the motor, but also a particularly compact design. The entire range is available with both AC and EC technology. In addition to being particularly energy-saving, the integrated electronics also make it possible to implement any control, monitoring and maintenance functions – for both the smart home and Industry 4.0.

Leave a comment