If the international community is to succeed in stopping climate change or at least slowing it down, the heating sector will need to massively reduce its CO2 emissions. Efficient boilers and eco-friendly fuels such as hydrogen can play an important role in this. The regulations vary from country to country, but in Europe it appears that in future, it will only be permitted to install appliances that can in principle also run entirely on hydrogen.

In Great Britain, the plan is to already implement this by 2025, and there is also a requirement prohibiting high additional costs during the changeover. Today, new condensing units can already be operated with 20 to 30 percent hydrogen, but a mass-market gas/air ratio control system for the combustion process has not been available so far for operation with 100 percent hydrogen.

Optimum air/fuel ratio

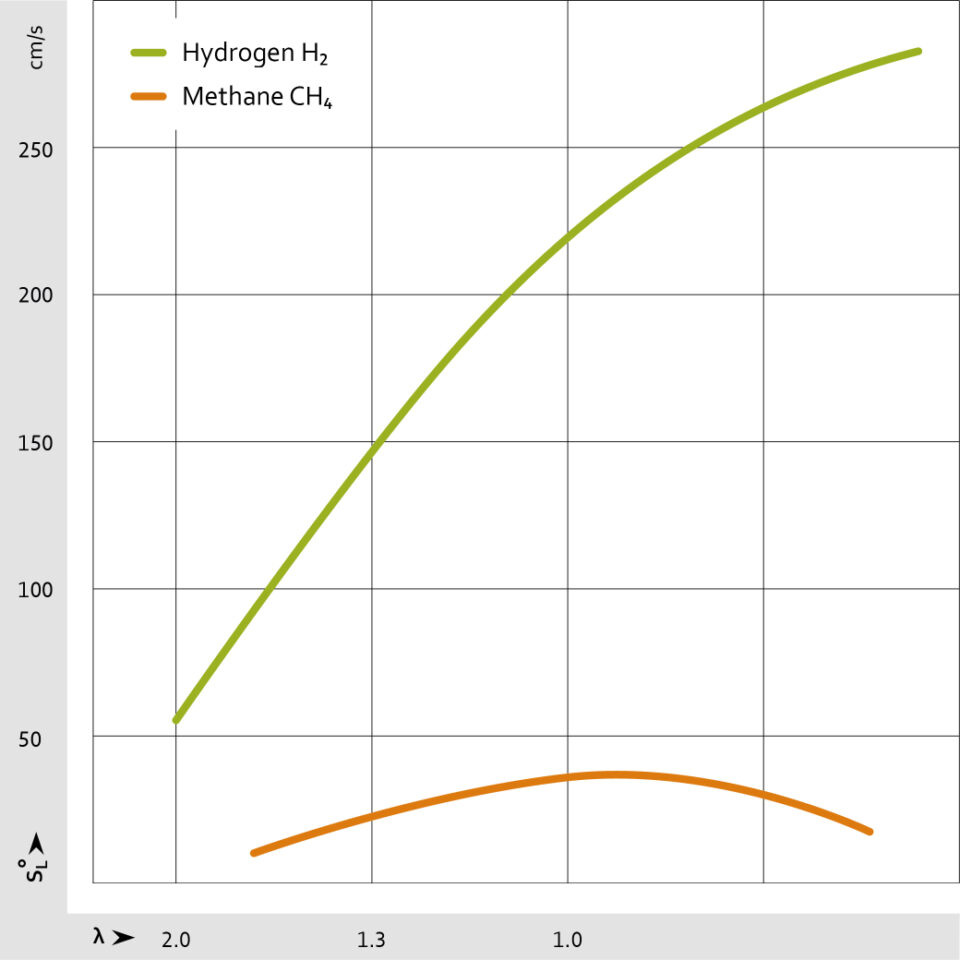

As a general rule, the combustion of hydrogen is no different to the combustion of other types of gas – the condensing boiler will only work efficiently if there is an optimum air/fuel ratio. This is always the case when the ratio is λ = 1.3. To achieve this reliably, it is crucial that the components of the gas/air ratio control system are perfectly matched. Two principles have proven effective in this respect: The mechanical-pneumatic ratio control system and the electronic ratio control system.

ebm-papst in heating technology

Efficient components & systems: blowers, venturi, valves and automatic burner controls from ebm-papst.

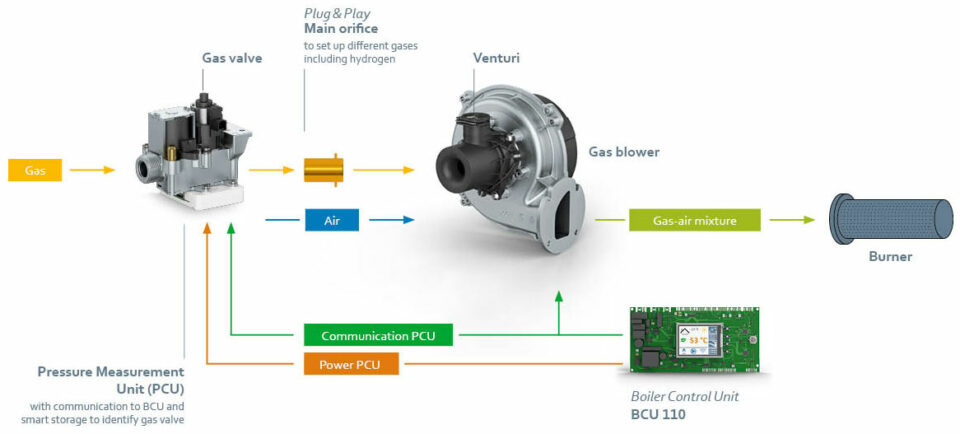

Both ratio control systems comprise a blower, venturi, gas valve, and burner controls. The most important difference is that, unlike pneumatic ratio control systems, the gas valve in electronic ratio control systems can be actively controlled. The advantage of this is that it is gas-adaptive and can automatically adapt to the combustion mixture. However, these two principles available on the market are not suitable for ensuring safe and efficient combustion if the unit runs entirely on hydrogen.

Electronic ratio control systems would not work because the hydrogen flame is not conductive and cannot, therefore, be used as a control variable for the ionization process. In contrast, the established mechanical-pneumatic ratio control system would work in principle, but the only way that the unit could run on hydrogen is with an inefficient gas/air ratio. A new system solution is therefore required.

A new gas/air ratio control system: CleanEco Sense

With CleanEco Sense, ebm-papst has developed a new operating concept that is suitable for both conventional and all-hydrogen operation (Fig. 1). Due to the laws of physics, the burner always needs to be replaced when switching over to hydrogen. However, the components supplied by ebm-papst (including the blower, venturi, gas valve, and burner controls) remain unchanged, meaning the changeover is affordable for end users.

To create the new concept, the combustion specialists at ebm-papst have combined the advantages of the mechanical-pneumatic and electronic ratio control systems and developed a so-called electronic-pneumatic ratio control system in which the gas valve can be actively controlled. The tried-and-tested F01 range of electronic gas valves (Fig. 2) is used for this purpose, expanded to include intelligent sensors. The combustion behavior of hydrogen was investigated in detail to enable safe operation.

Hydrogen burns differently to natural gas

The element is very reactive and has a high flame velocity. If it is only mixed in, this is not a problem provided the content is no higher than 30 percent. However, the situation changes if the unit runs on 100 percent hydrogen. The greatest risk in this case is “flashback”, which is when the flame migrates back from the burner toward the gas/air ratio control system in the opposite direction to the flow, thereby damaging the boiler (Fig. 3).

This is particularly critical during the ignition process as the flame spreads out very quickly after ignition. High pressure is produced as a result, meaning new fuel mixture cannot flow into the burner quickly enough.

In turn, when the unit is running, a critical state can occur in particular when lower outputs are requested. The reason for this is the high flame velocity of the hydrogen – the flame comes to a standstill where the flame velocity is as high as the efflux velocity. At the rated output, this happens at a sufficient distance from the burner surface. If the output is reduced, the efflux velocity decreases but the flame velocity remains roughly the same. The distance between the flame and burner reduces and there is a risk of flashback (Fig. 4).

Safe ignition, safe operation

As a result, the key is to master precisely these two aspects. The CleanEco Sense and the built-in intelligent sensors in the electronic gas valve make it possible to prevent flashback during ignition and operation.

To make the ignition safe, the amount of air is adjusted for the brief period of the start-up process in such a way that the reaction is less intense. In a conventional mechanical-pneumatic ratio control system, a fixed setting for the ratio is set once during installation using the main flow throttle and it can then no longer be changed during operation. However, with the CleanEco Sense it is possible to vary the λ value for the critical ignition phase. This solves the problem of flashback during start-up.

That then leaves the flashback during operation. To prevent this, it is important to know the volumetric flow for the mixture as it enters the burner. In a mechanical-pneumatic ratio control system, this can only be roughly estimated based on the blower speed. However, in order to reliably prevent flashback during operation, it is important to precisely control the efflux velocity.

The gas valve of the CleanEco Sense was equipped with intelligent sensors that permanently monitor the pressure in the system and the position of the stepper motor.

Both measured variables provide information about the quantity of gas conveyed. An algorithm developed by ebm-papst evaluates this data in the control unit and regulates the blower speed accordingly, ensuring that the efflux velocity does not fall below a critical level.

As a blockage in the exhaust and intake air system can also cause poor air performance, the system checks whether the vacuum generated by the blower corresponds to the setpoint before ignition takes place. If it does not, the safety valve does not open in the first place. As an additional benefit, the smart gas valve also makes it easier to control the combustion of natural gas or biogas.

High modulation level, simple to install

Regardless of the combustion mixture, the CleanEco Sense has managed to almost double the modulation depth of the blower to 1:15. As a result, the boiler output can be adjusted much more precisely to suit the actual demand. This reduces the amount of fuel required, which means lower CO2 emissions when the unit runs on natural gas. The advantage is that this high modulation depth can be achieved without the manufacturer or installer needing to configure complex settings on site.

The advantages of the CleanEco Sense at a glance

- Unit can run on natural gas, biogas, and 100 percent hydrogen

- To switch over to all-hydrogen operation, only the burner needs to be replaced

- Simple to install as the system adjusts itself

- Short development time as standard components are used

- Turn-sown ratio of 1:15 over the entire output range from 2 to 385kW

- Families of gases are automatically detected

- All components have been certified for hydrogen operation

Although the system is not gas-adaptive, the intelligent sensors make it possible to detect when the combustion mixture changes. In such cases, the boiler does not start at all, constituting an additional safety feature. The system has a modular design comprising standard components.

ebm-papst’s product portfolio offers the appropriate sizes of blower, venturi, and gas valve to cover the entire output range from 2 to 385 kW, meaning CleanEco Sense is suitable for both private households and larger commercial applications. In a nutshell, CleanEco Sense is a future-proof and flexible system that can play a major role in the energy transition in the heating sector.

Leave a comment