A climate-neutral future is only possible if the world gradually abandons fossil fuels and replaces them with clean energy sources. Heating is still a major contributor to global CO2 emissions. Although gas condensing boilers are already very efficient, a green fuel like hydrogen would make for a better carbon footprint. It will be a while before all gas-based heating systems are fully converted to hydrogen, but it’s only a matter of time.

Two trends: Admixture or 100 percent H2

Given the long service life of gas condensing boilers of over 15 years, it makes sense to develop future-proof solutions today. The United Kingdom is clearly the pioneer here: from 2025, all newly installed gas boilers in the UK must be designed to be convertible for 100 percent hydrogen operation at no significant expense. So a certain amount of time pressure exists. However, the industry is not unprepared. Heating technology manufacturers have been working on solutions for several years now, and there are various field tests throughout Europe that are trialing hydrogen use in local grids (see Box: H2 boiler for tiny house). On an industrial scale, however, development is still in its infancy.

The market is currently working in two directions: On the one hand, manufacturers are making their equipment fit for blending hydrogen with conventional natural gas. Ten percent is now possible without any problems, and 20 percent is currently establishing itself as the new standard. All in all, significant CO2 savings are possible. Although somewhat higher admixtures of around 30 percent are still manageable, further increases beyond this limit are not technically feasible. Therefore, the second line of development is to build devices that can be operated with both natural gas and one hundred percent hydrogen.

H2 boiler for tiny house

Intergas developed a boiler for a tiny house that uses 100% hydrogen (Photo | ebm-papst, Miquel Gonzales)

Dutch heating technology manufacturer Intergas has already tested what the future of heating could look like on a small scale. The company has developed a boiler that heats a tiny house with one hundred percent hydrogen.

The specialists from ebm-papst have contributed their know-how to the project from the very beginning and have also provided components. The gas valve and blower ensure that the boiler operates safely. ebm-papst was also able to assist with certification by the Dutch testing agency Kiwa.

Intergas is already implementing the next project: At the end of 2022, 33 houses near Groningen are to be connected to a hydrogen network.

What makes hydrogen special

In principle, manufacturers can retain the operating principle of their condensing units in both cases. However, due to the properties of hydrogen, three aspects in particular must be taken into account. Hydrogen is the lightest of all chemical elements with the lowest density. This means that it has a higher permeability than natural gas, and special attention must be paid to the tightness of the components in the boiler. The second aspect concerns the choice of suitable materials. More crucial, however, is the combustion behavior. For one thing, the flame velocity when hydrogen burns is eight times higher than with methane, and for another, it ignites very quickly.

With an admixture of up to 20 percent hydrogen, combustion behavior remains of secondary importance. However, it is still important to pay special attention to combustion. Hydrogen has a lower calorific value than natural gas and the Wobbe index, which is important for fuel gas exchange, is also lower. This means that it is necessary to make adjustments to ensure that the system is as efficient as it is when operated with natural gas. For the efficiency of the condensing units, it is therefore all the more crucial that the components of the gas-air composite system are perfectly matched. Only with an optimum mixing ratio of natural gas, hydrogen and air is the energy yield perfect. The CleanEco (pneumatic composite) and CleanVario (electronic composite) system solutions from ebm-papst, consisting of blower, venturi, gas valve and control unit, are already prepared and certified for the use of 20 percent hydrogen. Most of the gas blowers in the various performance classes, for example, have been tested by DVGW (Deutscher Verein des Gas- und Wasserfaches e. V.) and approved for H2 admixture (Figure in the article header). The same applies to the gas valves from ebm-papst. The blowers ensure the optimum mixing ratio of air and gas in every operating state (for more products, see Box at the end of the article).

For the admixture, the CleanVario electronic composite system in particular can make the most of its advantages because it is gas adaptive and can adapt to different fuels. The ideal mixture of fuel and air for low-emission and also efficient operation is achieved when the combustion air ratio is between 1.2 and 1.3 λ. To check whether combustion is proceeding at an optimum rate, an electrode directly on the flame measures the ionization current in the CleanVario. Depending on how high or low this is, the gas valve is electronically controlled to increase or restrict the gas flow. This makes it possible to control combustion independently of the fuel. Here, we have succeeded in further developing the reliability of the system beyond the state of the art by intelligently linking all actuators and sensors. The ionization technology works reliably up to an admixture of 30 percent hydrogen. At 100 percent, however, it does not. The ionization current is then barely measurable.

Safe ignition, safe operation

Fig. 2: The graph shows the flame velocity as a function of the air concentration. Hydrogen (green line) ignites much faster than methane (orange line), especially at high concentrations. (Graphic | ebm-papst)

When 100 percent hydrogen is used, combustion behavior takes on a crucial importance. Due to the element’s high flame velocity and reactivity, the heating technology industry is primarily concerned with the issue of safety. However, if you have a precise knowledge of its combustion behavior, you can safely control the combustion of hydrogen.

The ignition process is particularly critical. The danger is that a flashback will occur. In this case, the flame travels from the burner back toward the gas-air composite system, against the direction of flow. This happens when the flame spreads very quickly after ignition and the pressure is so high that new fuel mixture cannot flow into the burner fast enough. The flame therefore finds itself a way to continue feeding and migrates towards the fuel mixture (Fig. 2). One way to make ignition safe is to increase the air content during the starting process. The advantage is that hydrogen ignites at very low concentrations compared to natural gas. Once the critical ignition phase is over, the unit returns to efficient normal operation after a fraction of a second.

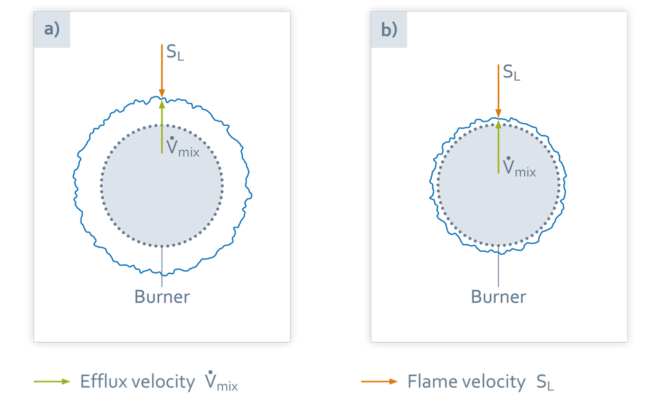

However, a flashback can also occur during operation, namely when lower outputs are called up. The reason for this is the high flame velocity of the hydrogen. The flame comes to a standstill where the flame velocity is as high as the efflux velocity. At rated output, this happens at a sufficient distance from the burner surface. If the output is reduced, the efflux velocity decreases and the flame migrates towards the burner surface (Fig. 3). Above a certain critical level, there is a risk that the flame will enter the burner and migrate upstream. Steps must therefore be taken to ensure that the efflux velocity does not fall below a certain level, even at low heating outputs.

Fig. 3: At full power (a), the efflux velocity and flame velocity are equal. The flame stabilizes at a sufficient distance from the burner surface. If the efflux velocity at low power (b) is too low, the flame may migrate into the burner and a flame flashback may occur. (Graphic | ebm-papst)

Gas-air composite system for 100 percent hydrogen

ebm-papst is working on a new operating concept to prevent flashback. Since economical and equally durable alternatives to ionization technology have yet to be found for the electronic composite system, a pneumatic solution makes the most sense as of now. The pneumatic composite system is usually set for a specific fuel-air ratio when it is installed. However, the system does not provide any information on the mixture flow rate entering the burner. In order to reliably prevent flashback during operation, it is important to precisely control the efflux velocity. ebm-papst is currently working on an electronic-pneumatic composite system that can do just that and is also prepared for the requirements, for example, by means of adapted startup behavior.

Ready for the future

It is difficult to predict exactly what the future of heating will look like. What is certain, however, is that hydrogen will play a significant role in enabling the global community to achieve its climate targets. For a transitional period, the admixture of about 20 percent to normal natural gas is likely. The components from ebm-papst are prepared for this application. And they will be, too, when 100 percent hydrogen flows into the boilers.

The hydrogen experts

The combustion specialists at ebm-papst started their first tests as early as 2 years ago and have accumulated valuable know-how in this area to date. Recently, there has even been a dedicated hydrogen laboratory in Landshut, where new processes for mixture control can be developed and tested. The following components and solutions are ready for hydrogen use today and are certified for an admix of 20 percent hydrogen:

- RadiMix VG 100:

The blower ensures the optimum mixing ratio of air and gas in every operating state. - G1G 170:

The blower is particularly suitable for maximum energy efficiency. - D01 | E01 | F01:

The gas valve range from ebm-papst is ready for hydrogen use. - CleanEco and CleanVario:

The two combustion control systems make full use of their advantages even with 20 percent hydrogen.

Leave a comment