Today, important measures to save energy include building highly insulated low-energy houses and renovating existing buildings by using insulating windows and thermal insulation composite systems on the building envelope. Sealing it off in this way means that only a small amount of heat energy is lost. However, this often results in no guarantee of sufficient air circulation, as the manual ventilation is usually less than is required. This may result in mold formation, the reproduction of pathogens and a lack of oxygen.

Centralized or decentralized?

Depending on how the building is used, planners and operators can choose between centralized, decentralized or combined solutions. In the past, centralized ventilation has shaped the market.

In the meantime, decentralized solutions for individual rooms or smaller units of use are also widely used, as they offer options for adapting to the user’s individual wishes, enable detailed individual billing and can usually be easily retrofitted. In addition, these devices are integrated directly into the building façade or windowsill and they do not require a duct system for supply and exhaust air. That is why they are ideal for renovating old buildings.

In centralized systems, heat recovery and air filtration are easier and more effective to implement and performing maintenance work is easier to execute according to plan. Both solutions therefore have advantages and can be combined if necessary.

Of course, the devices designed for the various ventilation concepts require different fans. Motor and fan manufacturer ebm-papst offers the right fan solution for the various requirements. The centrifugal fans in the RadiCal series are among those suitable for the AHUs used in centralized ventilation concepts.

RadiCal in scroll housing for centralized solutions

ebm-papst has taken a decisive step forward with the RadiCal in scroll housing. For the backward-curved EC fan, the company developed a vane anemometer for the most precise air flow determination – with just a one percent tolerance in the final value – and a closed scroll housing with integrated control electronics. In addition, the centrifugal fans are designed as a plug & play system, enabling ventilation system manufacturers to install them easily. Sensors for humidity and temperature are already integrated in the RadiCal. Other sensors, including those from third-party manufacturers, can also be connected and the entire system can be read, monitored and controlled via an open MODBUS RTU interface.

Available in five sizes between 133 and 225 mm, the RadiCal can be used in different buildings and, in the largest version, achieves an air flow of up to 1,800 m³/h. The EC fans also achieve a 34 percent higher efficiency than comparable centrifugal blowers and are up to 3.5 dB(A) quieter than these. This means that the blade passing noise is also significantly reduced. The compact construction and new design enable different mounting variants depending on the design of the ventilation system.

Compact centrifugal fans for high air flow rates

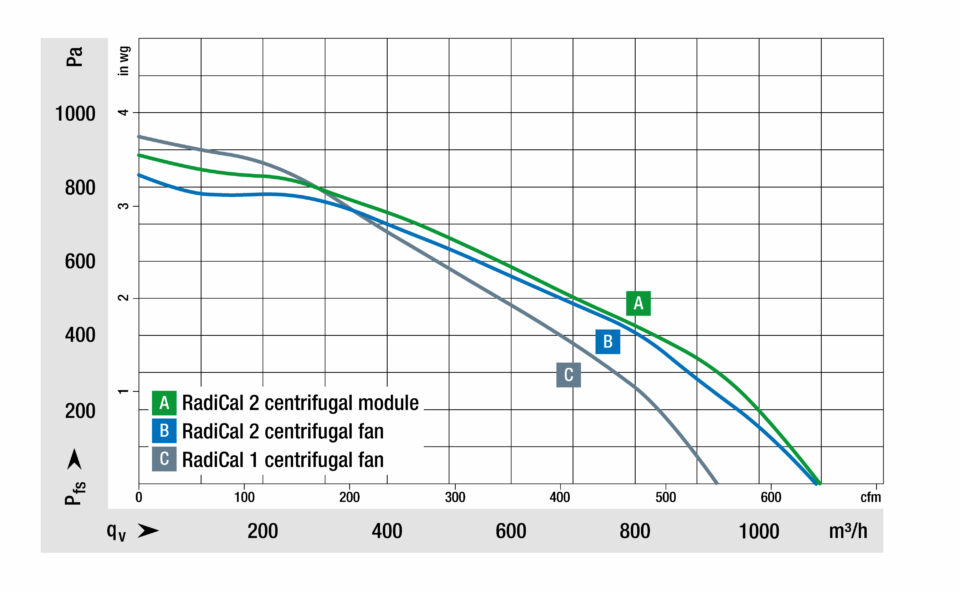

Ever-lower energy consumption is required for devices in centralized residential ventilation and air conditioning. Manufacturers are responding to this by designing their devices for minimal pressure losses resulting from installation. At the same time, ventilation and air-conditioning devices need to be as compact as possible so as to minimize their footprint and have sufficient space inside for additional components. For this reason, there is a demand for compact fans that deliver large air flows with low back pressure while operating as energy-efficiently and quietly as possible. ebm-papst designed the centrifugal fans in the RadiCal 2 series to meet precisely these requirements.

Several design details contribute to this, making it possible to achieve a ‘wound’ blade geometry that helps significantly increase efficiency and reduce noise. The blades are tilted both forwards and backwards and the profile of the inlet and outlet edges has been revised. This improves the flow behavior while at the same time increasing the strength of the fan impeller, which is made of resistant plastic. The wavy cover plate also improves the aerodynamic characteristics and, as a result, the air performance.

With the centrifugal module, i.e. the housing box, the inclined struts further increase the air performance. The axial height of the struts is selected to fill the backflow areas in the best possible way. There is also an enlarged intake diameter, which ensures a greater air flow rate through the impeller. The new, improved FlowGrid reduces the fan’s noise generation even with undisturbed inflow and thus represents a logical further development of the existing air inlet grille.

Room for room: decentralized ventilation

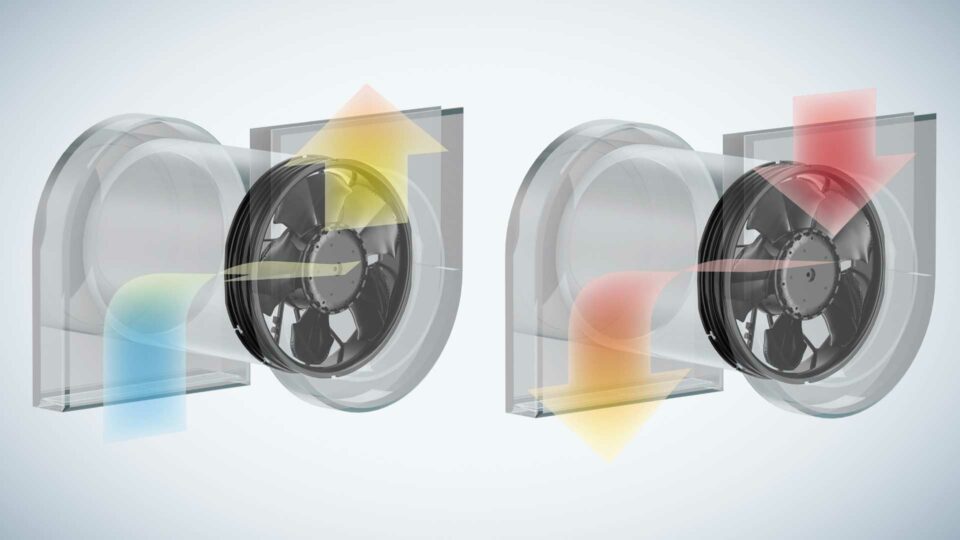

Decentralized residential ventilation units installed in the façade are not only suitable for renovation measures, but are also gaining in importance in new buildings where rooms have to be individually controlled, as in some residential buildings, in hotels and schools. Push-pull ventilation units convey used air from the living space to the outside (push) for a defined period of time, usually around 60 seconds. The fan installed in the ventilation unit then changes its direction of rotation, i.e. it reverses (pull).

During push operation, an integrated heat accumulator stores the heat energy from the exhaust air. In the pull phase, it is transferred to the fresh outside air so that it flows into the building preheated. A filter also clears dust and pollen from the air coming in from outside. Two units per room or zone are required to ensure balanced ventilation. In some cases, several rooms are ventilated using one pair of units. Due to their position in the residential and commercial rooms, decentralized units have to be particularly space-saving and quiet.

Push-Pull-Profi: AxiRev

In decentralized ventilation units, the direct proximity of the fans to the outside air poses a particular challenge: they have to deliver constant, level air flows even in changing wind forces. The AxiRev 126 reverse fan from ebm-papst was specially developed for this purpose. The characteristic curve for the pressure/air flow is very steep, which means that, even in stormy weather conditions, there are only slight fluctuations in the air flow. This means that wind and storms have little influence on the efficiency and function of the decentralized residential ventilation unit. In addition, the conveyed air volumes are almost identical in both directions of rotation.

This is ensured by the “flat” symmetrical blades that enable higher pressures and generate a very steep characteristic curve. Adjusting the number of blades and struts with an aerodynamic profile reduces turbulent trails. Together with the newly developed, extremely low-noise EC motor, this creates an operating noise that is perceived as pleasant.

The improved design also optimizes the efficiency: with a typical flow quantity of 42 m³/h per unit, the compact fan consumes less than two watts in a standard device and remains particularly quiet, even in partial load and minimum operation with high efficiency, thanks to the EC motor. The large speed range from 500 rpm to 4,200 rpm (variants also up to 4,700 rpm) ensures optimum adaptation of the air performance to the requirements. The compact design based on the predecessor model enables users to use the AxiRev 126 as a retrofit in a plug & play complete system. Compared to its predecessor, the new AxiRev 126 is more powerful, more pressure-resistant and quieter.

Indoor Air Quality (IAQ)

Indoor air quality is a decisive factor for the health, well-being and productivity of people who are indoors – in their homes, at work, at school, at the supermarket or when visiting a doctor.

Most Europeans spend more than 90 percent of their time indoors. We breathe in and breathe out up to 15,000 liters of air every day. So it is obvious that good air quality is not only a critical factor in outdoor spaces.

IAQ parameters

In indoor spaces, the number of people present, furniture, technical equipment or the building materials used directly affects the quality of the air. But the surrounding climatic conditions and environmental influences also have an impact. Various IAQ parameters emerge from this: temperature, humidity, carbon dioxide, fine dust and TVOC (Total Volatile Organic Compounds).

Data-driven solutions

With the help of digital solutions, ebm-papst offers OEMs, building operators and end users intelligent tools to improve air quality. ebm-papst can provide a lot of data relevant to IAQ via its cloud manufacturers and operators. The ebm-papst neo Building Solution platform processes and analyses data, and can be used to optimize the building control system. The platform therefore plays an active role in monitoring indoor air quality and controlling it in an energy-efficient manner. Algorithms learn from user behavior, building characteristics and environmental conditions, and, with the help of energy-saving fans, help to create an optimized indoor eco-system.

ebm-papst in ventilation technology

Fans for ventilation technology

From centralized to decentralized, in combination with heat pumps or for air cleaners, ebm-papst offers the right solution.

Leave a comment