Today, electronics cooling is largely based on axial compact fans, particularly because they are easy to integrate and offer high air flow rates due to their design. However, “normal” axial compact fans reach their limits when increasingly powerful electronics need to be accommodated in the same space or have an even more compact construction, because the aerodynamic resistances increase with increasing device compactness. To increase the cooling capacity, you could therefore simply connect two axial compact fans in series – running in the same or in opposite directions. In principle, this results in the required air performance. However, this solution requires more installation space and has disadvantages in terms of mechanical vibrations. In addition, the fans can have an adverse effect on each other in terms of aerodynamics, which can result, for example, in increased noise.

Optimized fan pair cools high-performance

electronics

For a power fan that delivers more power and is still as compact as possible, ebm-papst has therefore adopted a new approach: with the AxiTwin 100, the motor and fan specialists, in close cooperation with a company from the telecommunications sector, have developed a compact fan that has been designed as a contra-rotating system. With an edge dimension of 10 cm and a depth of 9 cm, four of these fans fit into a 19″ rack, as is typically used for cooling in blade servers.

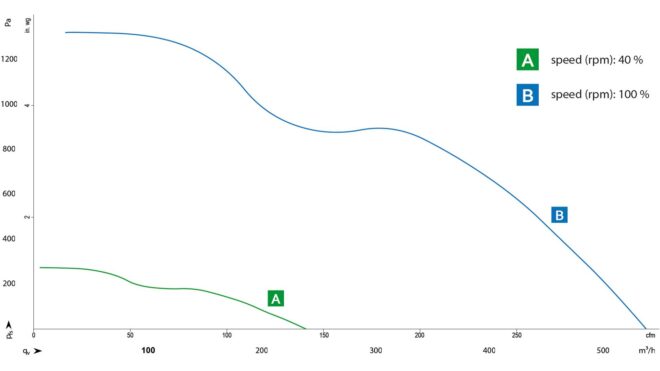

Up to 536 m³/h air performance at up to 1,300 Pa pressure. (Graphic | ebm-papst)

This guarantees reliable heat dissipation even when used with tightly packed electronics, as each fan delivers up to 536 m3 of air per hour and a maximum static pressure increase of up to 1,300 Pa. In doing so, the new fan for electronics cooling does not just combine two individual fans, but uses a newly developed flow geometry for the two consecutive blade rows which takes into account the aerodynamic operating point, thus numerically optimizing both at the same time.

Second-stage fan impeller: turbulence and swirl are reduced. The blade’s extreme sickle shape also contributes to noise reduction; the comparatively small surface of the blades increases efficiency. (Graphic | ebm-papst)

The fan then consists of two rotors that are connected via an innovative flange. The first rotor, with its five blades, is largely responsible for the air flow, while the second three-blade rotor is primarily responsible for the pressure increase. Around two thirds of the pressure is generated in the second stage. The second stage also reduces turbulence as a result of its sophisticated aerodynamics with its extremely sickle-shaped blades. It also contributes to noise reduction because the comparatively small surfaces of the blades increase its efficiency.

Noise Reduction with flange

A major advantage of the contra-rotating fan principle is the reduction of the speed component of the air flow in the circumferential direction. In this design, the flange between the two stages is not just a support structure or spacer, but a patented feat of engineering. It links both stages vibrationally in such a way that each stage attenuates the vibrations of the other. The double-sided bearing tube, which connects the two stages together, and the integrated guide blades mean that the design is extremely compact.

The flange is more than a spacer. Thanks to its optimized geometry, it reduces the generation of vortices and noise at the second stage. (Graphic | ebm-papst)

The geometry of the flange guide blades was also determined using the simulated flow field between the two rotors at the intended device operating point. This minimizes vortex generation at the guide blades and interaction of this vortex with the second row of blades, thus contributing to noise reduction. The flange is made of aluminum, which ensures high rigidity and at the same time enables good heat dissipation.

Powerful EC drives with new electronics

The driving forces behind the fan impellers are energy-efficient GreenTech EC drives with a motor power of up to 180 W. The three-phase motors are also very compact, work with a high level of efficiency both in normal partial-load operation and at full load, and are designed for continuous operation thanks to electronic commutation. The newly developed 300-W electronics also have a lot to offer. They have not been integrated into the motor, but have been installed in the corners of the housing for even better heat dissipation and therefore an even longer service life. This means that the surface of the flange can contribute to cooling them too.

The individual stages only require a small connection board on the motor for the winding. Standardized signal inputs such as PWM input, analog control input, as well as tach/alarm output signals, can be integrated individually as required. In the standard version, the fan has a PWM input and an open collector tach output. Optional humidity protection is also available for demanding environments.

The flange links both stages vibrationally in such a way that each stage attenuates the other. (Graphic | ebm-papst)

The two-stage design of the contra-rotating system also ensures the necessary redundancy for applications with critical 24/7 availability requirements, such as computers at major banks. If a single rotor fails, there will not be any backflow as the other rotor will continue to rotate. Each stage can be controlled separately, but always in coordination with one another. The speed ratio is defined, but it can be altered separately in individual cases, for example in order to optimize efficiency or reduce noise levels in certain ranges of the power level.

The AxiTwin 100 is an extremely powerful compact fan with small installation dimensions for applications where a lot of computing power needs to be cooled in a small space. Its range of applications extends across all cutting-edge technologies, from rack cooling for blade servers and extremely diverse information technology solutions to super computers in the field of blockchain technology. Application-specific modifications are also possible, as the design can be adapted to other sizes.

Leave a comment