Today, air conditioning in Germany is responsible for around 35 percent of energy consumption and around 120 million tons of the greenhouse gas CO2 per year. These emissions have to be reduced by more than 40 percent to achieve climate protection targets by 2030 and to become less dependent on energy imports. At the same time, it is important to balance energy and health requirements. Even with optimum insulation and hermetically sealed building envelopes, an air exchange must be ensured in order to prevent damage to the building’s structure, such as mold formation, and an impact on the air quality. Push-pull systems for decentralized residential ventilation are a practical solution for this. They ensure a demand-based, controlled supply of fresh air while keeping energy consumption low.

Heat recovery during ventilation

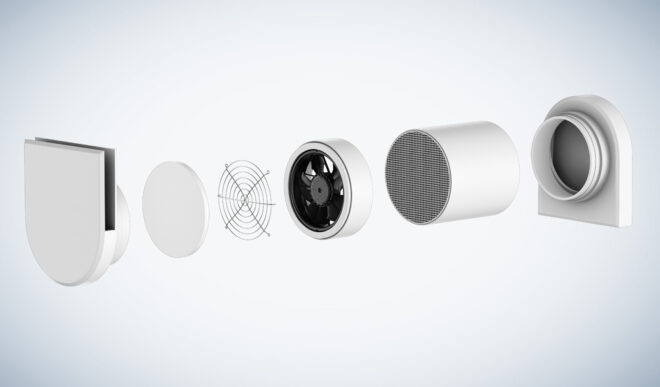

Push-pull ventilation units convey used air from the living space to the outside (push) for a defined period of time, usually around one minute. The fan installed in the ventilation unit then changes its direction of rotation, i.e. it reverses (pull). During push operation, an integrated heat accumulator stores the heat energy from the exhaust air. In the pull phase, it is transferred to the fresh outside air so that it flows into the building preheated. A filter also clears dust and pollen from the air coming in from outside. Two units per room or zone are required to ensure balanced ventilation. In some cases, several rooms are ventilated using one pair of units.

The units for decentralized residential ventilation are easy to install; they are easily integrated into the building façade. However, this poses a challenge for the fans used: even with changing wind forces, they must deliver an air flow that is as constant as possible in both directions of rotation. However, that is no problem for the new AxiRev reversing fan, which ebm-papst developed especially for the requirements in this type of push-pull application.

Steep characteristic curve, high pressure increase

The EC motor and fan geometry have been selected so that the fan is designed precisely for the operating points commonly used in push-pull systems. The characteristic curve for the pressure/air flow is very steep, which means that, even in stormy weather conditions, there are only slight fluctuations in the air flow. In typical applications, S2 classification as per DIN EN 13141-8 for wind pressure susceptibility is achievable. This means that wind and storms have little influence on the efficiency and function of the decentralized residential ventilation unit. The blade design is almost symmetrical and ensures that the characteristic curve and so too the volume of air conveyed are identical in both directions of rotation. In a push-pull application, the fan then typically changes the direction every 60 to 70 s, meaning that residential ventilation can work effectively in a paired operation.

The characteristic curve is very steep, which means that even in stormy weather conditions, there are only minimal fluctuations in air flow (S2 classification as per DIN EN 13141-8 for susceptibility to wind pressure). (Graphics | ebm-papst)

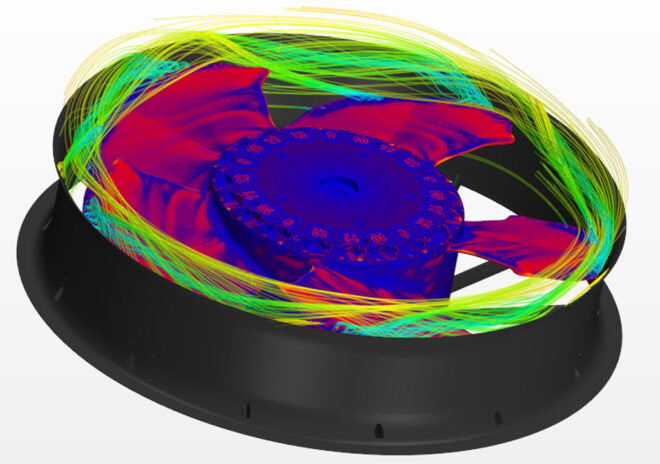

This is based on a wide range of design and aerodynamic details. These include, for example, the “flat fitted” blades that enable higher pressures. The patented blade design with striking blade tips and the openings at the blade ends minimizes the noises induced by tip gap vortices, which reduces the noise emissions. Matching the number of blades and struts also plays a role in this context. The thirteen struts with an aerodynamic profile also reduce turbulent trails, which ensures a very good psychoacoustic noise quality. This means that the fan is not only quiet but its operating noise is also perceived as pleasant. This also applies to both directions of rotation and, of course, the three-phase EC motor developed specifically for this area of application without irritating commutation noise, and switching between the directions of rotation cannot be heard.

Energy-efficient and suitable for retrofits

Thanks to the motor and aerodynamic optimizations, the fan only consumes a small amount of energy during operation. With a typical flow quantity of 42 m³/h per push-pull unit, a standard device is less than 2 W. As EC motors work at high efficiency even in partial-load operation, this also applies if the ventilation is only in minimal operation, for example because no-one is present in the rooms. The large speed range from 4,200 to below 500 rpm also covers this operating mode. The fan can be infinitely adjusted, e.g. in terms of humidity, temperature and CO2 content of the ambient air. The wide speed control range enables perfect adaptation to each application.

The patented blade design with striking blade tips and the openings at the blade ends minimize the noises induced by tip gap vortices, which reduces the noise emissions. (Graphics | ebm-papst)

With a diameter of 126 mm and a height of 26 mm, the new fan is very compact. It is supplied as a complete system that can be plug and play and is also suitable for retrofitting, as the footprint and dimensions are the same as the previous model. Therefore, the fans are easy to exchange without having to change the design of the device. The user then benefits from a significantly increased air flow, increased efficiency (7 percentage points per single fan) and a 5 dB(A) decrease in noise level. The air flow, efficiency and noise advantages provided are in comparison with the previous version 4412F in a typical application.

Leave a comment