Formula One and ventilation technology have more in common than it might appear at first glance: Both racing teams and fan manufacturers employ the latest materials and look for ways to reduce weight and network their products with their environment. Joint interests also exist in the field of aerodynamics. What these are and just how important aerodynamics is to Formula One is explained by Geoff Willis, Technology Director of the MERCEDES AMG PETRONAS Formula One Team, in the following interview.

Which common factors and differences exist between Formula One cars and fans in your opinion?

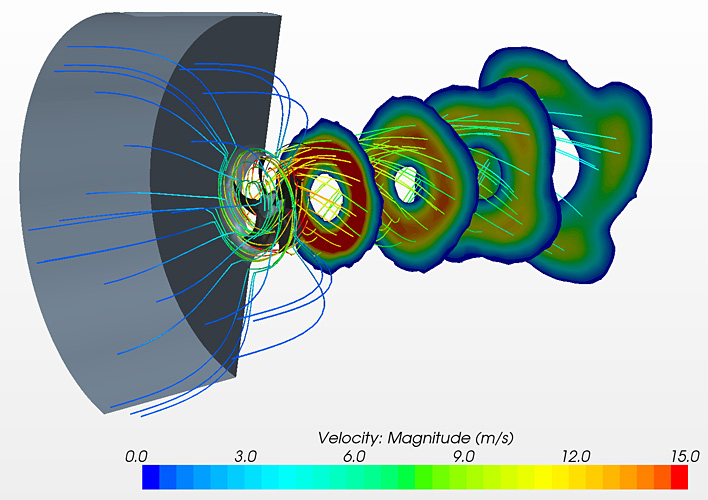

In our dealings with engineers from our Team Partner ebm-papst it became apparent that our work is actually very similar. Whether we are working on fans or on Formula One, we often employ the numerical methods of computational fluid dynamics (CFD) and are constantly looking to improve our products. What’s more, the activities at both ebm-papst and MERCEDES AMG PETRONAS revolve around low-speed aerodynamics*.

So the engineers speak in the same terms regardless of whether they are talking about fans or Formula One. The differences lie in the solutions we develop and the types of flow involved in our work. Whereas rotating flows play a major part with regard to fans, we are primarily concerned with the so-called ground effect which arises as a result of producing downforce so close to the ground.

*Low-speed aerodynamics refers to the branch of aerodynamics involving flow velocities of up to approx. Mach 0.3.

How many members of your team work on the aerodynamics of Formula One cars?

There are around 70 aerodynamics experts, engineers and specialists in our team who are directly involved with this topic. On top of that there are another 80 people who provide technical support in this field. They design and construct the models or are responsible for the technical aspects of the wind tunnel. To help coordinate the work, the aerodynamics department is divided into several sub-groups. Each of these has all the resources it requires to concentrate on a certain part of the car or specific tasks.

What are the most important aspects of your work in the area of aerodynamics?

One aim is to increase the downforce to give the cars better grip and to permit faster cornering. We also look for ways to reduce drag, as this saves fuel and helps us achieve better lap times. But the most important thing – as the drivers are always telling us – is the vehicle balance. A car has to have the right amount of grip at the front and rear and at the same time handle well on cornering. Which is why we sometimes sacrifice a bit of absolute downforce in the interests of obtaining a more consistent downforce.

How do you go about measuring balance?

Nowadays we have the means to gather plenty of data which provides us with information on all the forces acting on the car and how we can alter these. The finer details however come from the drivers. They can give us a better idea of how quickly the forces build up on entering a corner for example. So their feedback is vital to our work.

What developments have there been over the past few years with regard to the aerodynamics of Formula One cars?

Frequent changes to the rules have brought a lot of new challenges with them, leading to certain significant modifications in recent times. One of the areas concerned has been the aspect of safety. This has involved modifying the geometry of the car to provide better protection for the driver and reduce the amount of damage in the event of collisions. At the same time it is of course always important to keep an eye on the effect of such changes on the aerodynamics.

The new generation of turbocharged hybrid power units introduced in 2014 presented us with another interesting challenge. With a turbo-charged engine, we have to cool the combustion air exiting the compressor, which can be well over 200C, before it enters the engine so we need significant extra cooling capacity in the car. This means that we have to trade off engine performance with chassis performance.

It would be easy to imagine that Formula One cars are already so sophisticated that there cannot really be much room left for improvement. So where do you keep getting new ideas from?

The more we learn about how the car functions, the more we discover potential for further enhancement. In particular, we are gaining a better understanding of the interaction between the various design components of the car, enabling us to engage in an ongoing improvement process based on a comprehensive approach. And our capabilities in the areas of simulation and virtual engineering are growing to match the increasing complexity of the tasks.

You mention computer simulation. What is the purpose of this procedure and how important is it in relation to testing in a wind tunnel and on the track?

In all areas, the number of tests and the test times are subject to tight restrictions. The proportion of wind tunnel tests to computer simulations is 50:50. Ten years ago, CFD methods were limited capacity so were used as analysis tools, mainly on concepts after they were tested. These days they form an integral part of our design process. Testing on the track is of course important as well, but we only have the opportunity to do so before the season starts and twice during the season. We sometimes also run aerodynamic experiments on the Friday of a race weekend. So from the point of view of time, these tests are of lesser significance. The important thing is that we manage to combine all the elements of wind tunnel, CFD and track testing in a constructive way to come up with new findings.

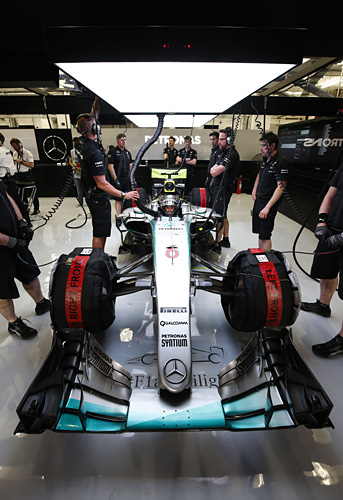

Strong partners

ebm-papst is supporting the MERCEDES AMG PETRONAS Formula One Team again for a second season. As Team Partner, the fan specialists developed energy-efficient attachment cooling solutions for the F1 W05 Hybrid racing cars in 2014 which cooled the temperature-sensitive components of the vehicles to the optimum operating temperature whilst the car is stationary. For 2015, the technology leader worked closely together with the F1 team to develop cooling solutions specially designed to vastly improve working conditions in the team’s Garage during the hotter races.

Leave a comment