If you want to save money and energy with your fans, motors, and turbo compressors, efficiency – or η – is probably the most important indicator. After all, it shows how efficiently machines can convert power input into useful power output. If efficiency is high, a large proportion of power input gets to where it is supposed to go. If, on the other hand, it is low, power is mainly lost as waste heat.

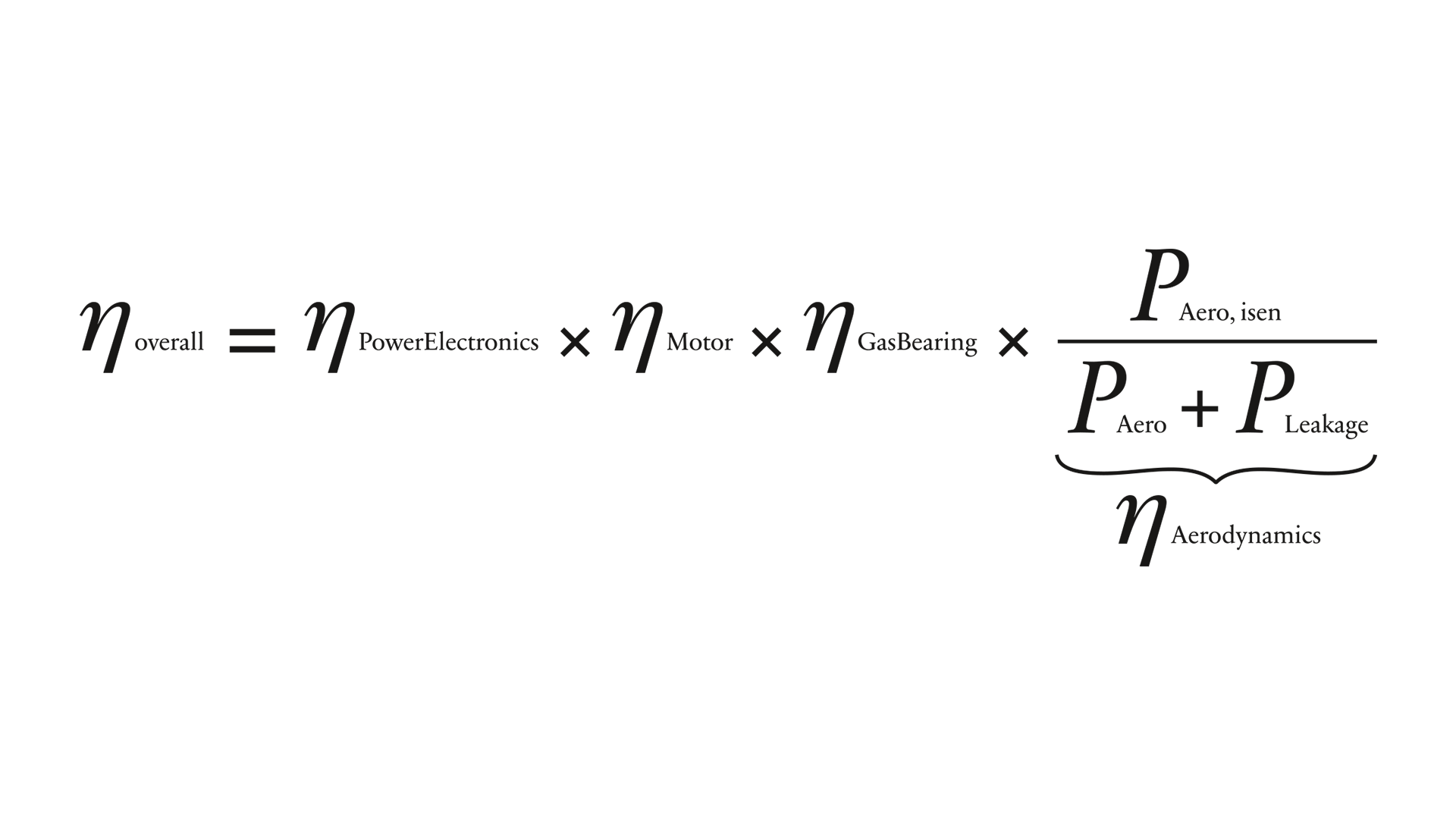

The efficiency referred to in this attractive formula is the overall efficiency ηoverall of an oil-free turbo compressor. It is the mathematical product of many other efficiencies, namely of each individual component that delivers power when compressing refrigerants and other gases.

This includes upstream power electronics (ηPowerElectronics), which control and transmit the electric current to the motor, as well as the motor (ηMotor), which converts the electrical energy into mechanical energy. The efficiency of the oil-free gas bearings (ηGasBearing) is also important. This is because it provides information on how smoothly the rotor is running, in terms of power loss and wear, with the compressor impeller in the bearing, in order to rotate at up to 300,000 revolutions per minute and compress gases efficiently.

The last piece of the puzzle for calculating the overall efficiency of a compressor is the efficiency of the compressor stage with the compressor impeller (PAerodynamics). Compared with the other components, this formula breaks down exactly how this efficiency is made up. First, the ideal power consumption of the compressor stage (PAero,isen) – i.e. the power that the stage could provide if there were no losses.

Second, the actual power consumption (PAero) and the power loss due to leakage (PLeakage). The ratio of the ideal power to the power actually used, including leakage, is then used to describe the efficiency of the compressor stage. Finally, the efficiencies of all the components can be multiplied together. The result is the overall efficiency of the turbo compressor: a value between 0 and 1. A result of 0.7 means that the turbo compressor uses 70 percent of the power used to compress gases.

Leave a comment