What does retrofit in Air Technology mean?

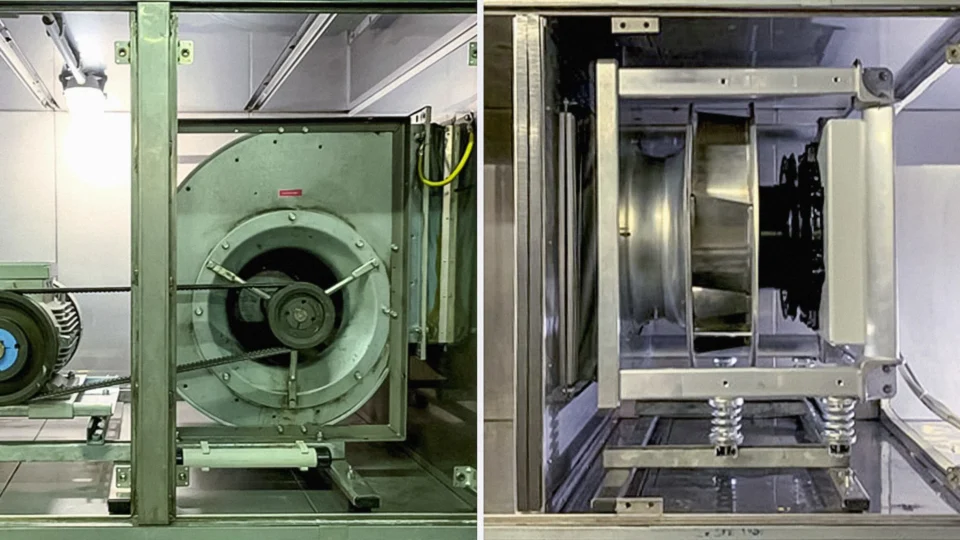

Retrofit refers to the retrofitting or modernization of existing technical systems with the aim of improving their performance, efficiency or functionality. In Air Technology, this typically means replacing old, sometimes belt-driven and therefore maintenance-intensive AC fans with highly efficient, maintenance-free EC fans with integrated control electronics, optimized air flow control and reduced noise levels.

Typical retrofit applications

- Ventilation systems in office buildings, schools and hospitals

- Air conditioners in trade and industry

- Refrigeration appliances in the food industry

Advantages of a retrofit

- Higher energy efficiency: EC fans achieve significantly higher efficiencies than traditional AC models. The integrated Speed control enables demand-driven operation and reduces energy losses.

- Noise reduction: Aerodynamically optimized fans such as the RadiPac C or components such as AxiTop or FlowGrid can significantly reduce noise emissions – while at the same time increasing air performance.

- Simple integration: Aerodynamically optimized fans such as the RadiPac C or components such as AxiTop or FlowGrid can significantly reduce noise emissions – while at the same time increasing air performance.

- Long service life and low maintenance: EC motors are characterized by high reliability and low maintenance requirements. The integrated electronics protect against overload and voltage fluctuations.

The process of a typical retrofit:

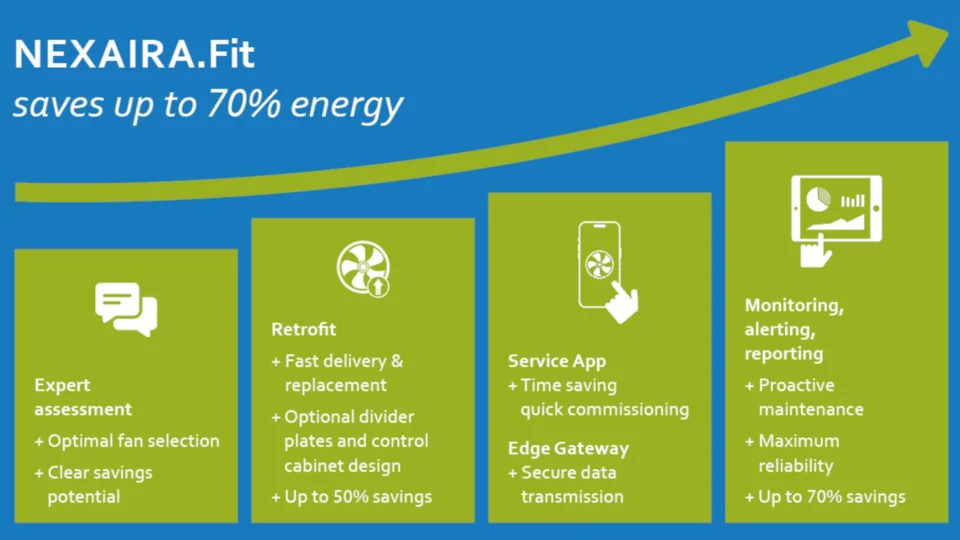

Digital retrofit with NEXAIRA.Fit: efficiency meets connectivity

With NEXAIRA.Fit, ebm-papst offers a pioneering solution for digital retrofitting in Air Technology. The combination of advanced fan technology, AI-supported services and cloud connectivity not only enables simple commissioning, but also intelligent, predictive maintenance. The hardware upgrade alone can save up to 50 % energy – and up to 70 % when combined with the digital services.

At the heart of NEXAIRA.Fit is 360° monitoring, including reporting and alerting, which allows installers and service companies to plan maintenance intervals at an early stage and coordinate service calls efficiently. The ebm-papst service app supports the fast and safe installation, commissioning and cloud connection of the fans. An integrated test run with automatic documentation ensures additional safety and traceability.

The further improved return on investment (RoI) compared to classic retrofit solutions is particularly noteworthy: The digital extension not only increases energy efficiency, but also operational reliability. This makes NEXAIRA.Fit the ideal tool for installers and service companies who want to implement retrofit projects efficiently, transparently and without headaches.

RadiPac: The retrofit class among centrifugal fans

The RadiPac product range from ebm-papst stands for powerful EC centrifugal fans. Thanks to their compact design, integrated electronics and high energy efficiency, they are ideal for retrofit applications in air conditioning and ventilation technology. RadiPac fans combine all the necessary functions in a “packaged” system – from intelligent control to optimized flow control – and thus enable easy integration into existing systems. A particular advantage for retrofit projects: Existing AC fans can be replaced with RadiPac EC models without costly modifications.

The backward curved impellers ensure high static efficiency, while the EC technology guarantees precise Speed control and quiet operation. RadiPac fans are available in various mechanical designs – such as with a support bracket or cube design – and can be flexibly mounted in a vertical or horizontal installation position. The combination of high efficiency, easy installation and robust design makes RadiPac fans the first choice for retrofit projects where reliable performance and fast implementation are essential.

Centrifugal and axial retrofit projects from practice

Even if retrofit projects in Air Technology are predominantly implemented with centrifugal fans such as the RadiPac series, axial panel fans are also used – particularly in refrigeration technology, for example in horizontal condensers or condensing units, where compact designs and high air performance are required. Significant efficiency gains can also be achieved here by replacing outdated AC fans with modern EC axial panel fans.

- Our retrofit at our own site in Mulfingen achieves energy savings of up to 50% – supplemented by digital added value.

- The St. Franziskus Foundation in Münster is replacing the ventilation systems in 14 hospitals with new radial fans, saving 920,000 kilowatt hours of energy.

- Chinese central air conditioning manufacturer KINFIT is modernizing its cooling towers with axial fans, thereby halving energy consumption.

Do´s and Don´ts for a successful retrofit

The five most important Do´s:

1. VISIT THE SITE IN PERSON

To be able to plan a retrofit, the company implementing it must visit the site to get an idea of what needs to be done. This is the only way to determine how the old fan can be removed from the building, and how the new ones can be installed. On site, it is also easier to determine which transport equipment can be used and is required.

2. MAKE A PRECISE SCHEDULE

Shopping centers or factory buildings can often only pause their activity for a short time. Therefore, it is necessary to identify these potential time windows early on, and then plan the retrofit accordingly. A precise schedule should also be created for the conversion itself

3. DOCUMENT THE CURRENT SITUATION OF THE SYSTEM

It is essential to document the desired target set-up of the system together with the customer before retrofitting. As the systems can sometimes be 20 to 30 years old, it is important to discuss, for example, whether parts of the building have been added at a later stage or removed, as these may also need taking into consideration, or not.

4. ORDER MATERIALS IN ADVANCE

If the retrofit is to be a success, there is no time to procure materials once the process has started. This applies in particular if work is carried out on Sundays or public holidays. Therefore, all materials should be procured early on.

5. CHECK FOR CONTROL SYSTEM COMPATIBILITY

Today, modern fans often have either an analog-based control system, using a 0-10 V signal, or are controlled via a ModBUS interface. In this regard, it is important to check whether these options are compatible with the conditions on site. If this is not the case, a suitable interface should be planned and implemented.

Retrofitting fans

Rising costs, legally required reduction of CO2 emissions – retrofits provide a solution.

The five most important Don’ts:

1. FOCUS ONLY ON THE FAN

A ventilation system is more than just the fan. Therefore, both the whole system and the surrounding area should be incorporated into the planning of the retrofit. This enables you to identify the overall function of the system and to take specific aspects, e.g. pollutants in the exhaust air, into account.

2. RELY TOO MUCH ON THE DOCUMENTATION

Even if there is comprehensive documentation of the system, important key points should be directly verified again. This can help to rule out the possibility that parameters may have changed over time without being documented.

3. PLAN WITHOUT FUNDING

If your fans are efficient, the retrofit will pay for itself quickly. However, you can recoup the costs even faster if you make use of the many funding opportunities available. You should not forget to apply for these and factor them in right from the start of the project.

4. IGNORE DOCUMENTATION

All of the steps in the project must be precisely documented – from agreeing the target set-up through to energy consumption before and after the retrofit. This helps all the parties involved, and often makes funding possible.

5. ASSESS THE COSTS AND BENEFITS FOR THE SHORT TERM

You should always look at the long term when assessing the cost of a retrofit project. Without a doubt, a retrofit costs money at the beginning. However, over time, operators quickly recoup these costs and also save money on a day-to-day basis.

FAQ – Frequently asked questions about the retrofit

What does a retrofit cost?

The costs vary depending on the application, but are usually amortized within a few years through energy savings. Often even faster with digital solutions.

Does the entire system have to be replaced?

No. Retrofit means targeted retrofitting – it is usually sufficient to replace individual components such as fans or controls.

How long does the conversion take?

Thanks to customized solutions, retrofitting is often possible within a few hours.

What funding opportunities are available?

In many countries, there are subsidy programs for energy-efficient modernization. ebm-papst provides support in selecting suitable programs.

Conclusion on retrofitting in Air Technology

Retrofitting is a central building block for reliable Air Technology. With the intelligent system solutions from ebm-papst, existing systems can be made more efficient, reliable, noise-optimized and future-proof – taking into account technical, economic and practical aspects.

Interview with retrofit expert Ralf Mühleck

Ralf Mühleck is Team Leader Commercial Ventilation at ebm-papst and knows the right product for every project.

Leave a comment