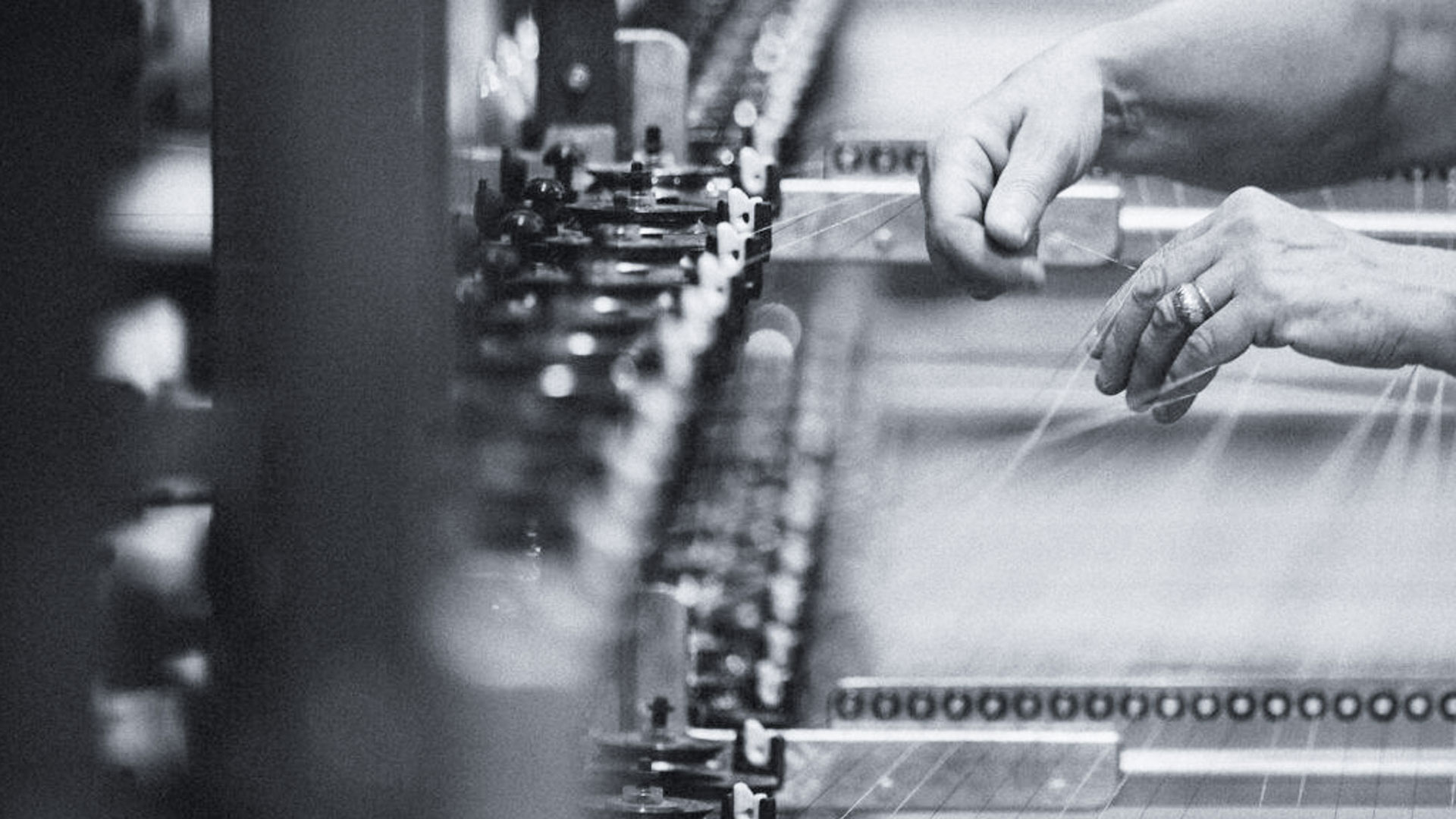

Fabrics that are flowing or robust, playful or elegant, modern or classic, striking or discreet: in the Deveaux fabric storage facility in Saint-Vincent-de-Reins, about 70 kilometers north-west of Lyon, you can see and feel that this is where creativity and skill are interwoven. Deveaux has been producing textiles for over 200 years – currently with 37 employees and 63 looms. Every day they transform the finest cotton into up to 10,000 meters of fabric. And both man and machine depend on good air quality in the mill.

Thibaud von Tschammer, Managing Director of Deveaux, explains: “We process cotton into luxurious fabrics and stable humidity is essential for this. If it is not right, the looms react and productivity can be halved. If the air is too dry, for example, the yarns can easily break. However, the ideal levels vary from material to material.” It’s just as important that circulation keeps the air clean: “The fine dust from the cotton otherwise settles on the textiles and makes work in the mill unpleasant,” says von Tschammer.

The height of fashion

That’s why 20 years ago, Deveaux decided to work with installation company J.Moos, also based in the Rhône-Alpes region, to bring their ventilation system up to the then state of the art. But like moths to a cloth, the ravages of time gnawed away at the system. “At the time, we had a particularly advanced ventilation system installed by J.Moos, which made a decisive contribution to the quality of our fabrics and hence to our good name in the textile industry. But like fashion, technology continues to evolve. So we decided that the large system, which was consuming a lot of energy and was not flexible enough to adapt to changing requirements, needed to be upgraded again,” says von Tschammer.

Enter FanGrid

At the end of 2022, there was a clean-out: Instead of the four outdated AC axial compact fans in the ventilation system, Deveaux received a total of 48 centrifugal fans from the RadiPac series from ebm-papst. With two fan walls of 24 RadiPacs each, it is ebm-papst’s largest FanGrid project in France to date.

It was clear to Hugues Letombe, the owner of J.Moos’ supplier Deressy Charlas, that it had to be RadiPac for Deveaux’s requirements. As he explains: “When J.Moos contacted us about retrofitting old generation axial fans, I immediately thought of ebm-papst and its new K3G and RadiPac fans because of the requirements. They work very efficiently, can be easily plugged together to form a FanGrid thanks to their cube design and have automatic resonance detection on board.

This point was particularly important for Deveaux’s existing system so that it would last a long time. And indeed, this solution is proving to be more efficient and reliable, much quieter, and more energy-efficient and sustainable.” Pascal Magnin, Technical Director at J.Moos, confirms: “The new system is four times as quiet as the old one, and Deveaux is currently making energy savings of 30 percent.”

Leave a comment