Today, modern centrifugal and axial fans are very efficient and quiet. However, once installed in an application, their behavior will change if the inflow or outflow conditions are disturbed. In an air-conditioning unit, fans are ultimately a means to an end. Negative effects are therefore usually due to function. Flaps and filters can change the air flow and the distance to walls and heat exchangers, as well as the use of guard grills, have an impact. Typical selection programs (Fig. 1) can only take into account these effects to a limited extent, as they use the values determined under laboratory conditions (Fig. 2).

Fig. 1: Selection programs should be configured in such a way that they request as many parameters as possible that are based on the installation situation. (Photo | ebm-papst)

These must ultimately be based on reproducible measurements under (undisturbed) standard conditions. In the application, however – due to the installation conditions in the respective unit – the turbulence is more or less pronounced. This turbulence leads to noise generation that is difficult to calculate under real conditions. Once installed in the unit, the documented values often do not match reality.

Fig. 2: The data sheet specifications are determined on the test stand. These must be based on reproducible measurements under (undisturbed) standard conditions. (Photo | ebm-papst)

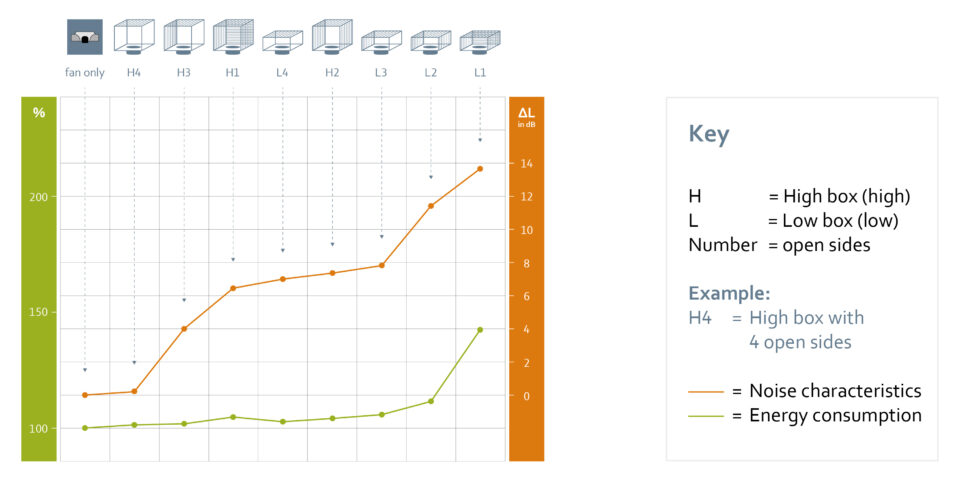

Figure 3 shows how energy consumption and noise change depending on the intake-side installation situation – depending on how much the housing hinders the flow, i.e. whether it is drawn in axially from the front, centrifugally from all sides, or on one side. In the worst case, this significantly increases power consumption and noise level at the same operating point.

To ensure safety, axial fans usually have to be fitted with guard grills. Here, it is important to adapt the geometry of the guard grill to the flow control in order to generate as few losses and noises as possible. Nowadays, individual acoustic effects of guard grills have a much stronger effect than a few years ago. Modern fans in themselves work so quietly that the effects caused by the guard grill can be heard more strongly. It is therefore not useful to rely only on catalog values when it comes to power consumption and noise emissions. Selection programs should therefore be configured in such a way that they request as many parameters as possible that are based on the installation situation.

Fig. 3: Energy consumption and noise change, depending on how the housing influences the flow – i.e. whether it is drawn in axially from the front, centrifugally from all sides, or on one side. (Graphic | ebm-papst)

Taking the installation situation into account during development

Since interactions between the fan and the application can always occur, fan and motor specialist ebm-papst endeavors to take the subsequent installation situation – wherever possible – into account when developing a fan. Here, application expertise gained over the course of decades is incorporated, and the wide range of disciplines involved in development work closely together, starting with high-performance simulation tools and test stands, right up to the psychoacoustic testing laboratory.

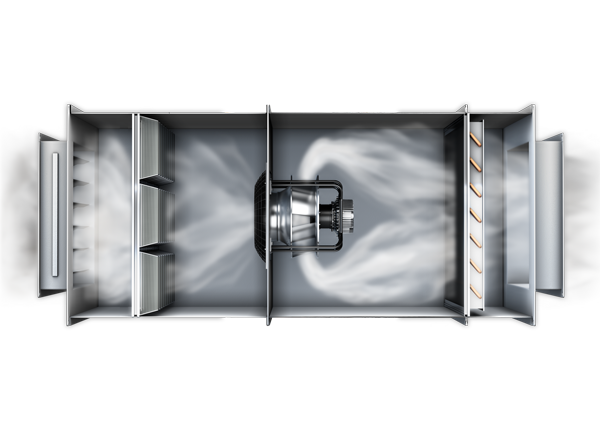

Fig. 4: With the RadiPac fans, ebm-papst not only optimized the impeller, motor, and control electronics in terms of energy efficiency and noise emissions, but also took into account the actual installation situation in AHUs. (Photo | ebm-papst)

The latter is becoming increasing important. This is because today an air-water heat pump set up outside can annoy the neighborhood with disturbing noise, even if it may meet the German “TA” noise regulation. To be on the safe side, fans should be optimized in accordance with psychoacoustic criteria in addition to the common evaluation of the noise level.

If the subsequent installation situation is taken into account during development, this significantly improves the results, as shown in the example of RadiPac fans (Fig. 4). Here, ebm-papst not only optimized the impeller, motor, and control electronics in terms of energy efficiency and noise emissions, but also took into account the actual installation situation in AHUs. The wide optimum efficiency range of centrifugal fans means that the fans operate at practically every operating point with the lowest possible power consumption, and there are also no unpleasant surprises in terms of noise levels.

FlowGrid improves noise level

Fig. 5: The FlowGrid is suitable for centrifugal fans (left) and axial fans (right) (Photo | ebm-papst)

There is a worst case for every manufacturer of an AHU: When installed, the selected fan is too loud or not efficient enough. In the worst-case scenario, market launch can be delayed by this considerably. In precisely such cases, it may be worthwhile to ask the specialists. Passive components such as the FlowGrid air-inlet grille (Fig. 5), which is suitable for axial and centrifugal fans, can also minimize unwanted effects after installation retroactively.

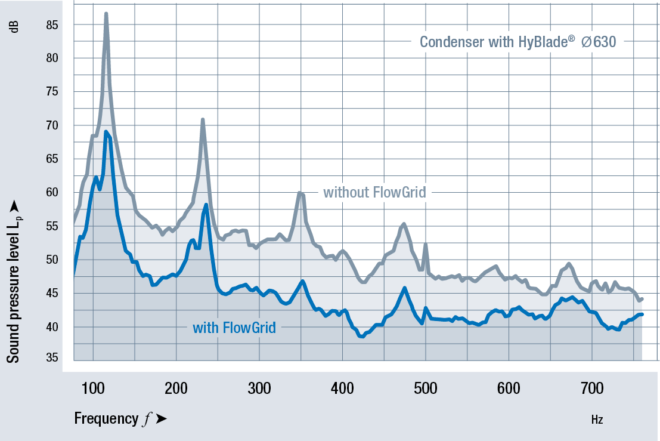

If the fans used are retrofitted with this, this drastically reduces noise-generating turbulence in the inflow without reducing the air performance or power consumption (Fig. 7). Good results can be obtained here in noise-sensitive applications such as heat pumps, residential ventilation units and air purifiers for classrooms.

Fig 6.: Additional parts such as the FlowGrid can also be used to reduce unpleasant effects after installation. (Graphic | ebm-papst)

Development under real conditions

Anyone wanting to be on the safe side right from the start should involve the fan manufacturer in an early development phase of their unit. In the case of large and small fans, it is equally worthwhile to precisely analyze and evaluate the flow situation and find suitable optimization measures. As a competent partner, the fan and motor specialists at ebm-papst constantly set the standard here when air-guiding units are concerned to prevent problems in advance or to achieve the best possible noise and efficiency before product launch.

Leave a comment