Mr. Gläss, how does one come to develop a record cleaner?

For Reiner Gläss high-quality compo[-]nents and reliable suppliers are the basis for successful products. (Photo | KD Busch)

It just kind of happened. When I started my own business 20 years ago, I knew that I didn’t want to be a company employee my whole life. I’ve always been a very creative person, so first I built furniture for hi-fi systems. A lot of people thought that was great — but nobody bought any. Another milestone for me was the development of a yin-yang aroma lamp. Some retailers were interested in it, but then the audio industry got in the way. My advisor at the employment agency asked me one day if I could make him a machine that would bevel CDs. So I developed one. He was so excited that he recommended a hi-fi dealer for me to sell it to. He ordered three of them right away. And that’s how I went into production with it. Parallel to that I offered a test unit to a hi-fi magazine. They published a report along with my phone number. From then on my phone was ringing off the hook.

How did you get from CDs to records ?

A trade journal offered to present me at their stand at Europe’s biggest trade fair for the hi-fi sector. I got more and more requests there to develop a system for washing records. I couldn’t really see a market for that; it seemed like too much of a niche to me. But I got more and more calls asking if I was already working on something. So I announced on my website that I was developing a fully automatic record cleaning system for the analog fans, and I also informed the retailers and importers that I knew through the CD beveling machine. Now we serve 50 countries through established importers. The Vinyl Cleaner Pro is keeping us pretty busy.

What makes it special ?

It’s compact and it cleans both sides of a record at once. Most competing products don’t do that. I was also the first to include ultrasound. The Vinyl Cleaner Pro is very quiet, completely automatic and easy to use.

And who buys the Vinyl Cleaner Pro ?

I target collectors and audiophiles; some of them have never warmed up to CDs. They’re almost all men; some have their own music rooms. And their systems cost an average of 30,000 euros. It’s an exciting clientele from every educational level.

How important is it to you as a developer to have a healthy sense of curiosity for such unusual products ?

I’m always open to new things. Customers are always contacting me because they’re looking for something special. And when the requests pile up, that’s when I get to work. At the moment I’m in a slow phase. After all the stress, I really needed a break. You can feel it when the creative juices aren’t flowing right anymore. But I’ll develop something again. I can’t just sit around, that’s nothing for me. And I’ll notice when something slowly begins to grow….

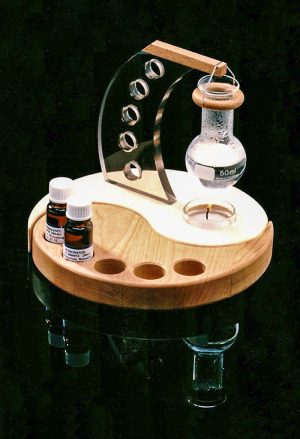

A milestone for the creativ thinker: the yin-yang aroma lamp.

Do you tinker alone or in a team ?

The creative process mostly happens alone. For me it works best when I have peace and quiet. If I run up against my limits, I’ll go to my colleagues and we’ll talk for a while. Then I’m alone again. Sometimes I’ll describe an approach to the team and we’ll talk about it. Then all the ideas are put on the table, no matter how crazy they are.

How does your path from a crazy idea to a series product look ?

It usually starts with creative chaos, beginning with a very simple sketch that I implement in my tinkering phase. Then I look for suppliers. That brings structure into the process. Purchasing is a very important aspect. And then there are all the surrounding bureaucratic things that you have to take care of. Now I have an employee who helps me there.

On the subject of suppliers: the LPs are dried by waterproof diagonal fans from ebm-papst. Why did you choose these components ?

How the Vinyl Cleaner Pro works

The record is inserted vertically into the unit. A mixture of distilled water and cleaner is pumped into the cleaning chamber from below, covering the record to just below the label. The record turns through the liquid. Surplus water runs to the bottom and is filtered. Then an ultrasonic transducer starts and rollers contact the record from both sides and rotate in opposite directions. When the cleaning process is completed, the rollers are retracted, the liquid flows downward, and the record is dried by two fans.

Because they’re very reliable. I tested other components, but none of them won me over. The Vinyl Cleaner Pro has to be quiet, and for that the fans are perfect. At first I had problems with the liquid. If somebody used too much cleaner, foam would form. The foam would get into the fan area and cause failures. So I started to take the fans apart and dip the electronics in synthetic resin to seal them. What a mess ! Finally I contacted ebm-papst, who offered me completely sealed fans. Even under power in a bucket of water, they won’t fail. That’s really cool.

Now your record cleaner is being copied by Asian manufacturers. Are counterfeit products a problem for you ?

No, they’re no problem. I’ve bought a few and taken them apart. As far as quality, noise and functionality are concerned, they’re a disaster. So no danger (laughs). I notice whether counterfeits get a foothold in the market, and I keep improving my product in the background. By the time they catch up, it’s already obsolete.

Leave a comment