Drawing on its core competencies in aerodynamics, motor technology and electronics, fan and motor specialist ebm-papst launched the RadiCal centrifugal fan series more than 10 years ago, a series that has since proven its worth in many ventilation and air-conditioning systems.

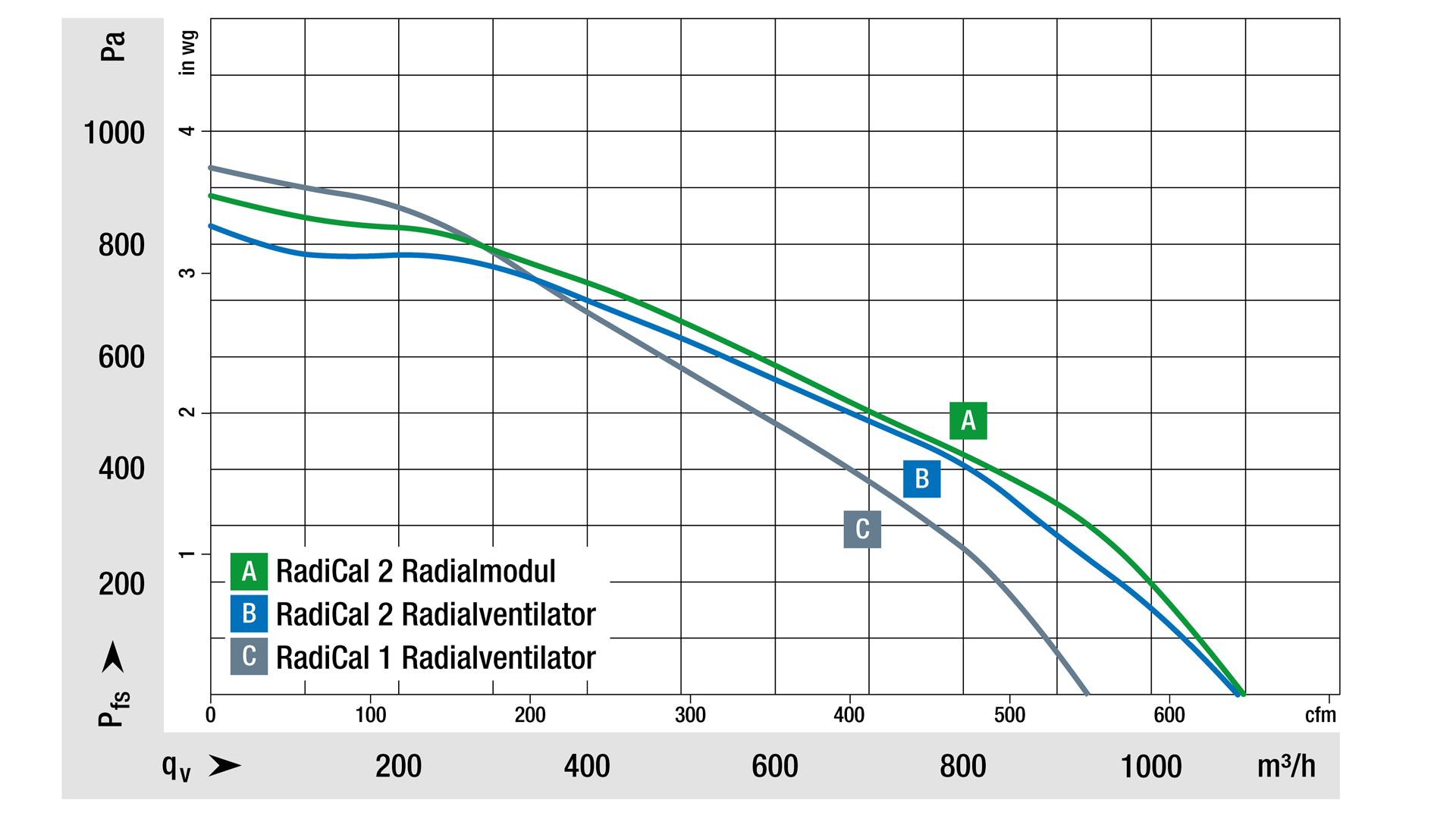

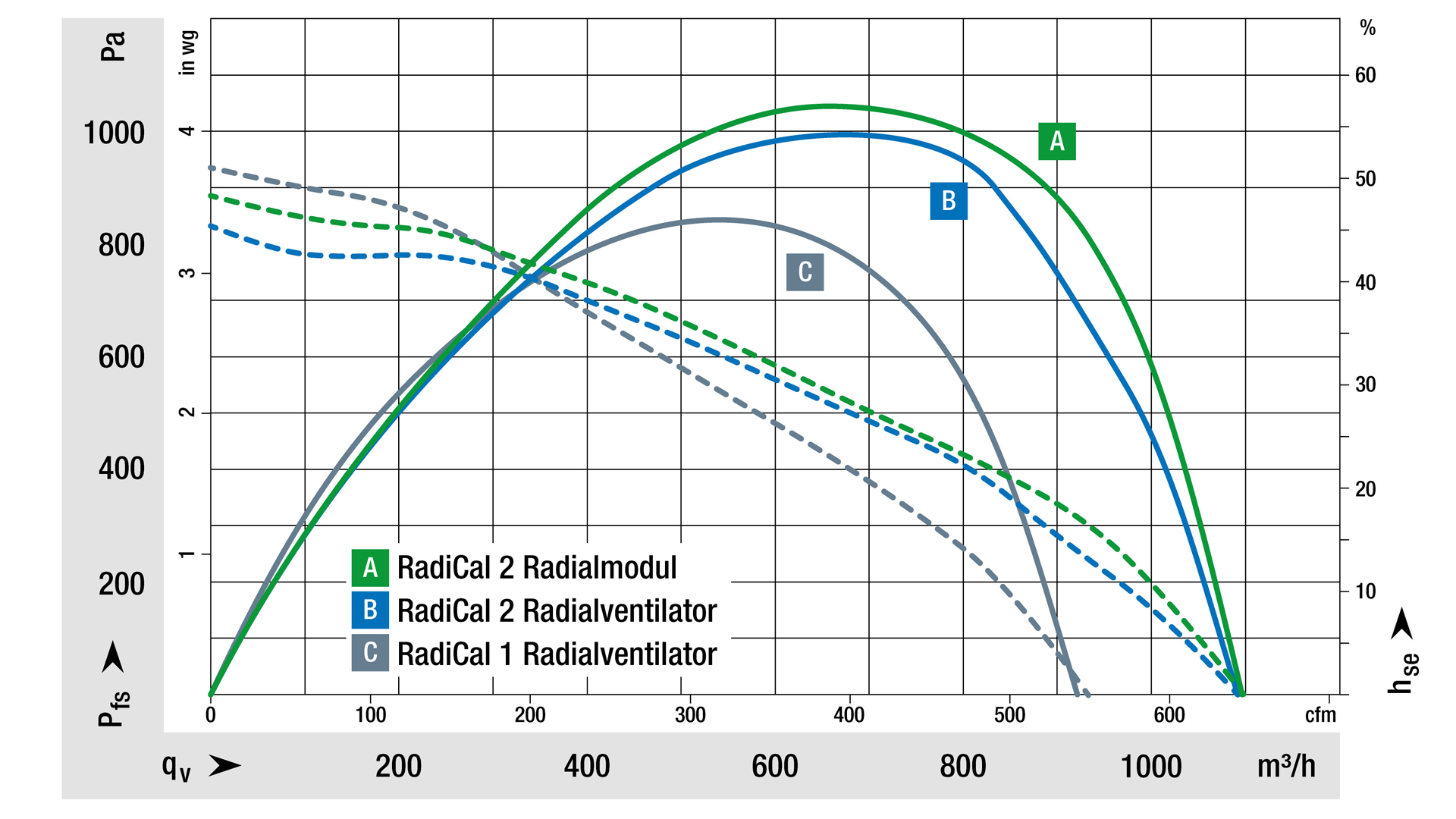

Now, the Mulfingen-based company is introducing a second generation of the fans with particularly impressive air flow rates, alongside remarkably compact dimensions and pleasant noise characteristics (Figs. 1 and 2).

The main contributors to this have been aerodynamic optimizations, refined GreenTech EC motors, and further improvements in control electronics. An additional size has also been included, making it even easier for users to find the right solution.

New blade design improves aerodynamics

With the aid of high-performance development tools and production engineering, the first step was to optimize the design of the impellers in line with aerodynamic criteria.

In this, the developers benefited from plastic production, which now offers design freedom in all three dimensions – making it possible to achieve an innovative blade geometry that helps significantly increase efficiency and reduce noise.

The “twisted” blades are curved into each other and the shape of the leading and trailing edges has been completely redesigned. This improves the flow behavior (Fig. 3) while at the same time increasing the strength of the impeller, which is made of resistant plastic. The corrugated impeller cover plate also improves aerodynamic characteristics and hence air performance.

The centrifugal module, or housing box, has also been completely redesigned. The inclined struts, for example, provide an additional boost to air performance. The shape of the struts can be varied over the axial height to avoid backflow areas as effectively as possible. There is also an enlarged intake diameter, which ensures a greater air flow rate through the impeller. With the size 190, for example, the intake diameter has been increased from 132 to 150 mm, which helps air throughput.

Significant noise reduction

There is further potential for improvement in clearance gap losses. Finding ways to improve the air gap, in other words the distance between the inlet nozzle and the impeller, is challenging because the gap will always have a certain tolerance for manufacturing reasons. In the case of the second-generation RadiCal fans, however, new manufacturing methods have made it possible to reduce the air gap significantly, depending on the size.

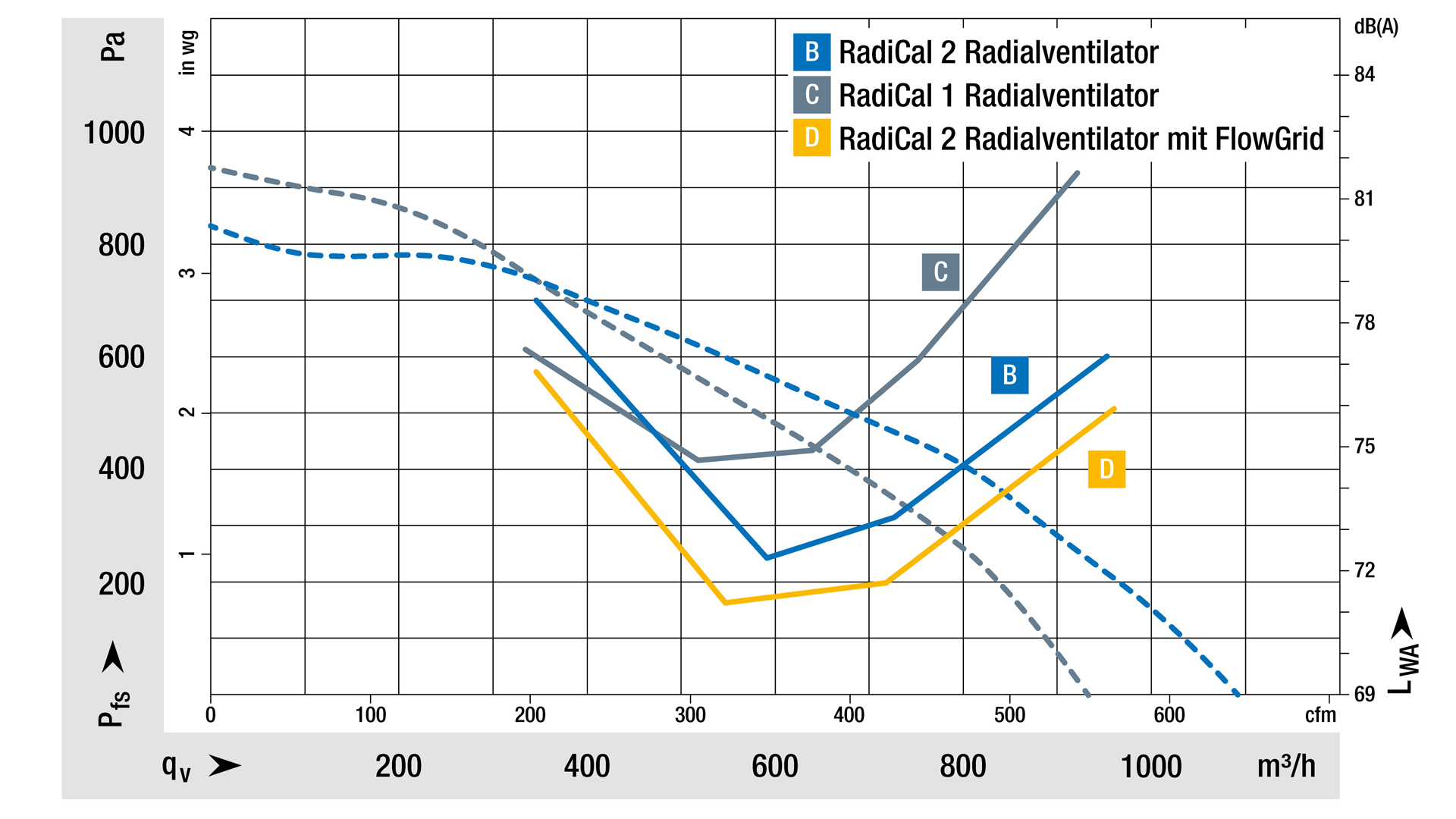

As a result, there is less turbulence, efficiency increases and noise is reduced (Fig. 4). The new air inlet grille also helps to prevent noise (Fig. 5). In this further development, the struts were initially dimensioned to minimize losses.

As noise analysis showed that the rotor area had a major influence on noise development, a cap was added to the center of the air inlet grille, which significantly reduced noise in the lower frequency range. Compared with the current series version, it is up to 2 dB(A) quieter when installed in a test rig (Fig. 6).

New motor generation

The new EC motors also contribute to noise reduction. Depending on the size of the fans, they cover a power range of up to 170 W for single-phase networks. Fans for three-phase networks and outputs of up to 1.5 kW will follow at a later date. There are no disruptive resonances when there is a change in speed.

In addition to good noise characteristics, the new generation of motors also boasts excellent EMC characteristics and durability. The commutation and control electronics are tuned to the motors and the air flow and operating point can be precisely adjusted.

Control and monitoring are possible either through 0 – 10 V/PWM or optionally through MODBUS-RTU starting from the 170 W variant. Networking via the communication bus then makes it possible to use the motor data for preventive maintenance measures, for example, or to quickly adapt the fans to changes in operating conditions.

Compact and easy to integrate

Since no other installation situation is the same, the new centrifugal fans are very adaptable. They are available as a motorized impeller, as a centrifugal module with ready-to-install housing or with a support bracket (Fig. 7).

Three different mounting levels are provided for the compact centrifugal module. If installation space is tight, users will appreciate another design detail: the backplate is smaller than the cover plate.

As a result, the direction of discharge is more in the axial direction. This is an advantage if there is little space in the centrifugal direction. The fans are also a few millimeters shorter axially than their predecessor. Thanks to the high air flow rates, a smaller size can now be used compared to the predecessor model, depending on the operating points.

The second-generation RadiCal fans will be available in the familiar sizes 175, 190, 225, 250 and 280. Size 206 is new and improves the power rating. This means that the right centrifugal fans are available for efficient residential ventilation or switch cabinet cooling, not only delivering high air flow rates, but also operating extremely quietly.

Leave a comment