The Netherlands has a space problem. More and more people are looking for affordable housing, but there are virtually no new construction areas which is why old developments are making room for new buildings. These buildings are more modern, better insulated, and have energy-saving heating systems. But not more space. So where to put the heat pumps, which have to be placed at prescribed distances from neighbors due to strict noise protection regulations? Where to put the technology or hot water tanks if there is no boiler room or equipment room? Cezar de Jong knows the answer to these questions: simply place the heat pump on the roof.

A crazy request

Cezar de Jong works at Breman Installatiefabriek, a division within the Breman Group that develops and manufactures heating equipment such as heat pumps. The whole roof project started in 2016. The company was asked to place the outdoor unit of an air-to-water heat pump on a gable roof. Dutch noise regulations require heat pumps to be placed only at a sufficient distance from the house. “We’ve been doing chimneys for about 30 years putting things on the roof is nothing new for us,” Cezar de Jong says with a laugh. “But designing the outdoor unit of a heat pump for lots of roofs with different slopes was a challenge.” The result was the EQ-Air.

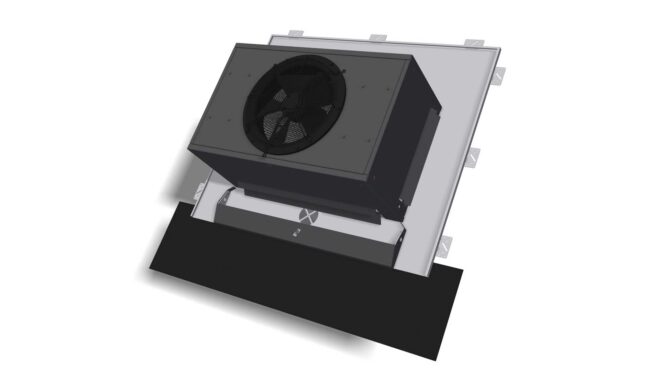

The EQ-Air from the Breman Installatiefabriek, the HyBlade sits on top of the housing. (Graphic | Breman Installatiefabriek)

An extraordinary decision

The EQ-Air is an air-to-air heat pump. A fan draws in outside air from three sides and sends it past a heat exchanger to the inside, from where it is distributed throughout the building. The conditions on the roof, close to the living spaces, gave rise to special requirements for the fan: “We needed a quiet, durable fan that could withstand the weather and work for different roof angles. In addition, we didn’t have a lot of time for development, and we also wanted a European-made product.”

That’s how in 2018, Cezar wound up at ebm-papst – with the HyBlade. This EC axial fan was actually designed for heavy-duty use in places such as trains and railroads. This means that it is robust, resilient, and has no problem with permanent heat, cold or temperature fluctuations. It is also very quiet even when running flat out, thanks to its blade geometry. Perfect conditions for the job on the roof: “With a diameter of 50 centimeters, HyBlade can process more air volume at a lower speed than with a smaller size, which also minimizes noise from the moving air.” The result: The HyBlade runs at a maximum of 55 percent power while emitting around 28 decibels – that’s quieter than a whisper.

The EQ-Air can also be combined with photovoltaic systems. With the envisaged performance and working hours of the HyBlade, Breman is looking at up to a 30-year warranty. (Photo | Breman Installatiefabriek)

A good idea

Meanwhile, supply bottlenecks put a lot of pressure on the project participants on both sides. Breman had received an order to equip an entire housing development with EQ-Air heat pumps. The delivery date was set and not far away. Open communication was the most important tool here: “All our contacts at ebm-papst told us honestly what was possible and what was not. We could and had to rely on a yes being a yes and a no being a no. That’s not always what you want to hear,” Cezar says with a laugh, “but essential for good collaboration.”

And that ensured that the delivery date could be met. Now, the Netherlands has its first housing development powered by rooftop air-to-air heat pumps. Over time, customer confidence in the product is also growing: “No one is offering anything comparable. This is a disadvantage at the beginning because potential customers initially prefer what they know. They can’t imagine that a unit directly on the roof won’t make a disturbing noise.”

The heat pumps in the housing development are proving to be very persuasive and the residents are delighted. Breman is receiving more and more orders. Demand for space-saving, efficient heat pumps is growing exponentially. And shows that a good idea always comes at the right time.

Leave a comment