Heating with heat pumps

Today’s heating systems demand concepts based on renewable energies. ebm-papst delivers low-noise and efficient components.

With the new version of the F-Gas Regulation ((EU) 2024/573), which came into force on March 11, 2024, the framework conditions for these refrigerants will become much stricter; the use of hydrofluorocarbons as refrigerants (HFCs) will be further regulated. This means that natural alternatives are the only way forward. However, these are flammable in most cases. When developing refrigerating systems and air conditioners, household refrigerators and heat pumps, manufacturers must therefore ensure that they only use components that meet the applicable standards for handling flammable refrigerants.

The F-Gas Regulation and the phased plan defined within it for reducing CO2 emissions (Fig. 1) means that manufacturers of air/water heat pumps, as well as chillers, evaporators and refrigerated cabinets, are increasingly using refrigerants with a low global warming potential (GWP), such as the natural refrigerant R290 (propane, GWP value = 3). However, a low GWP value requires rapid decomposition of the refrigerant when it enters the atmosphere. This can only be assured if it is chemically reactive, but high reactivity typically goes hand in hand with a high level of flammability. Special safety concepts are therefore required to ensure that nobody is harmed if there is a leak in the refrigerant circuit.

ATEX-approved compact fans for the safety concept

One – albeit rather elaborate – method is the use of restricted-breathing housings that prevent electronic components and flammable atmospheres from coming into contact with each other. However, another solution is usually more practical for air/water heat pumps: In the event of a leak in the refrigerant circuit, ATEX-approved compact fans (Fig. 2) ventilate the housing and prevent a flammable atmosphere from developing. Thanks to the fully encapsulated motor and electronics, they meet the requirements of EN 60079-7, Group IIC, up to T4 and DIN EN 60335-2-40 as standard.

Due to their compact design, the fans require little space for installation and can also be used for cooling electronics if required. They can also be used as the main fan for smaller heat pumps, such as those used for floor heating. The ATEX-approved compact fans are available in many variants and in different sizes with edge lengths from 40 to 200 mm and offer high air performance levels. Thanks to their aerodynamically optimized design, they operate quietly, are energy-efficient, and can be used for both intake and exhaust.

Drive design for the main fan in accordance with EN 60335-2-40

Even with the larger axial panel and centrifugal fans, which provide the necessary air flow over the evaporator in heat pumps, the electronics must not become a source of ignition if there is a leak in the refrigerant circuit. For this reason, ebm-papst has modified the electronic circuits of its fan drives in sizes 60, 74 and 90 so that they comply with EN 60335-2-40 for heat pumps with flammable refrigerants. This means that, in the event of a fault, the maximum surface temperature must be at least 100 Kelvin below the ignition temperature of the refrigerant used. Propane, which is very suitable due to its good heat transfer capacity and its low GWP value, has an ignition temperature of 470°C. The electronic assemblies, which have been tested and certified accordingly, ensure that their maximum surface temperature always remains below 370°C, even if a fault occurs, so that they do not become an ignition source.

Axial panel fans for particularly noise-sensitive areas

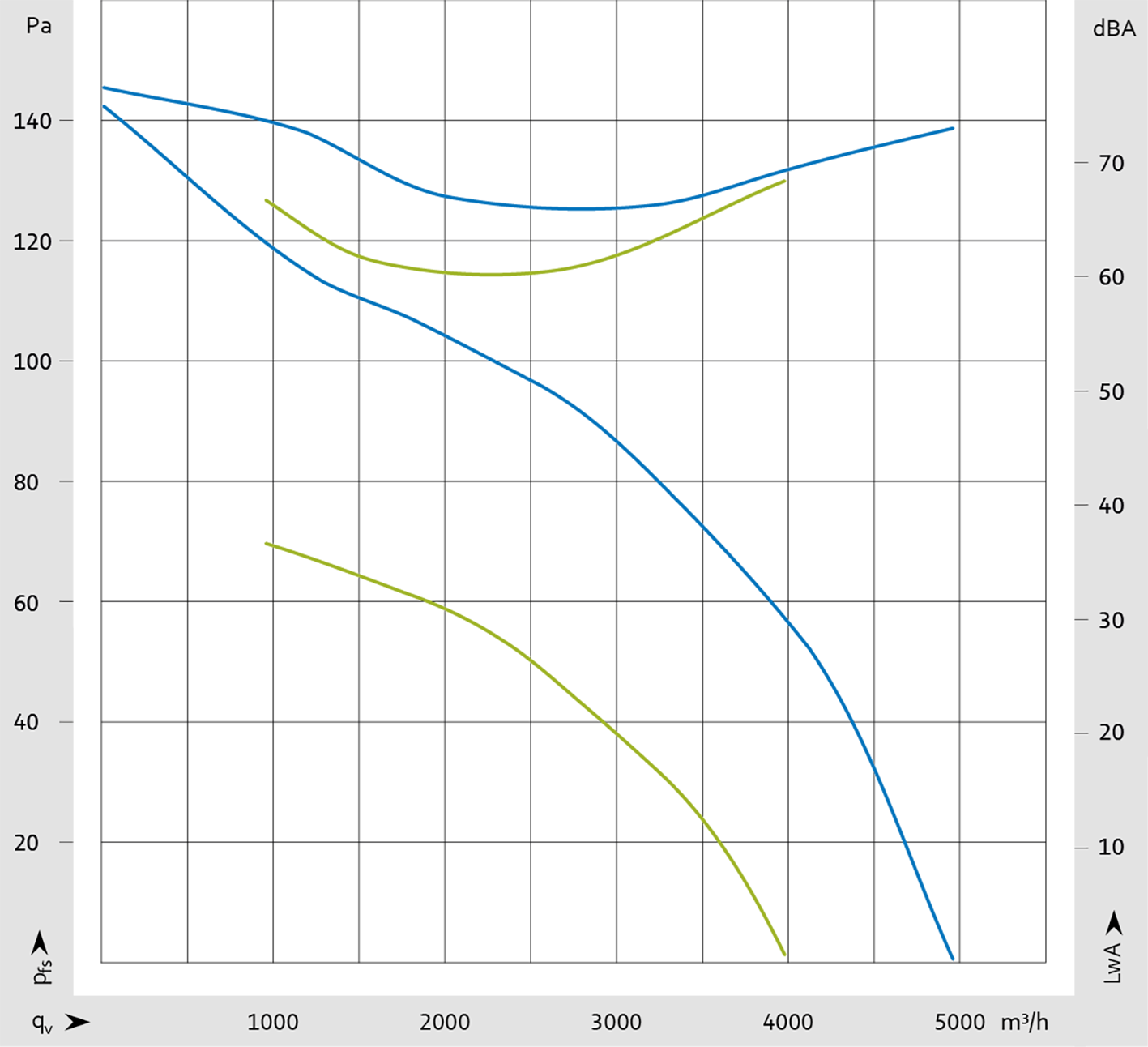

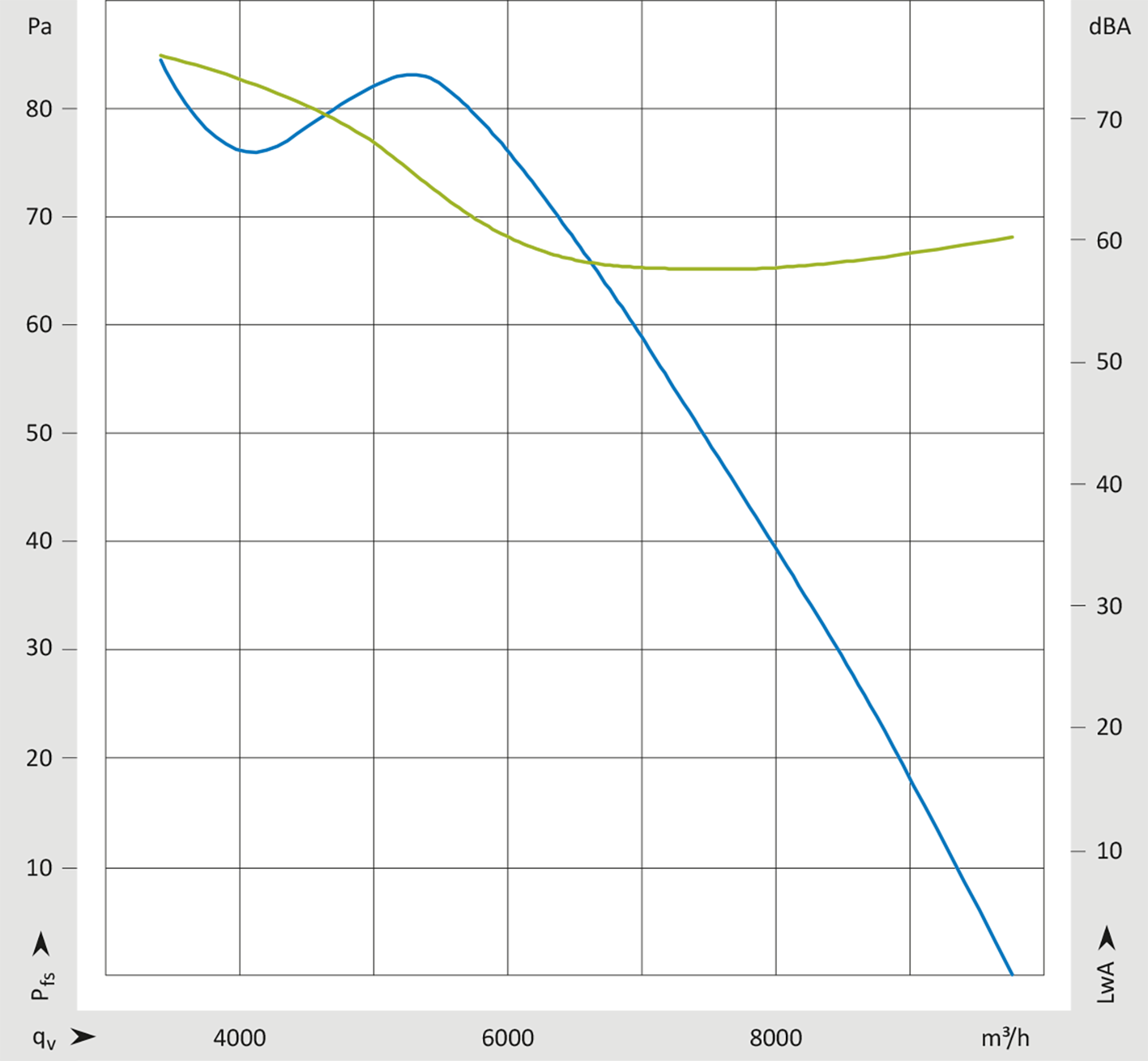

Anyone using air/water heat pumps will inevitably have to deal with the issue of noise. Noise levels are particularly relevant at night, when the limits of the applicable legal regulations must be observed both inside and especially outside of buildings (Fig. 3). ebm-papst has developed two fan series for noise-sensitive outdoor areas: AxiEco Plug-In and AxiTone (Fig. 4).

Both are also designed for applications with natural and flammable refrigerants (EN 60335-2-40) and are particularly quiet thanks to their special design (Fig. 5 and Fig. 6). While the AxiEco Plug-In in sizes 450 and 500 mm is suitable for heat pumps that require a large supply pressure reserve at the evaporator, the AxiTone in sizes 450, 500 and 630 mm is designed to deliver higher air flows at a lower back pressure if the heat pump design requires this. As all compact fans based on the fully encapsulated motors are suitable for use with flammable refrigerants as standard, there are many other axial panel and centrifugal fans that are also suitable for use with heat pumps, as well as chillers, evaporators, and condensers.

Based on many years of experience with heat pump applications, EC motors and their commutation electronics, ebm-papst has also developed inverter electronics (Fig. 7) that are suitable for speed-controlled permanent magnet synchronous machines (PSM), as typically used in compressors. They also reduce noise and simultaneously increase the efficiency of the heat pump.

Safety in refrigerated cabinets

Natural refrigerants are also used in other refrigeration applications, such as refrigerated cabinets. The ESM motor (energy saving motor, Fig. 8) set the standard for fan technology in this area several years ago. The compact EC motors are available both as OEM components for combination with the customer’s own fan impeller and as complete plug & play systems with perfectly matching individual components. In order to offer a safe cooling solution, the motors and complete systems comply with household appliance standard EN 60335-2-89 as standard. This is completely sufficient for most refrigerated display cases, as their cooling circuits can handle the refrigerant filling quantities specified in the standard, e.g. 500 g for propane. For refrigeration circuits with larger filling quantities, it may therefore make sense to split the circuits.

Leave a comment