Both industrial automation and intralogistics require powerful, reliable drive systems. To meet this need, ebm-papst offers a wide selection of motors, control electronics, transmissions, and brake and sensor modules in a sophisticated modular drive system that can be combined to create a customized drive. The electronically commutated ECI motors, for example, cover a power range from 30 to 750 watts in sizes 42, 63 and 80 mm. Different transmissions matched to the drives then ensure the necessary reduction ratio for the high-speed internal rotors. Users can choose between designs that are cost-optimized, particularly low-noise, or very robust.

High-performance gears for ECI motors

Optimax planetary gear units are among the particularly robust transmissions that are now available as a complete series to match the ECI drives, also in sizes 42, 63 and 80. Several design details ensure their high level of robustness – for example the fact that all gearing parts are made of hardened steel. In the two smaller versions, the sintered planetary gears are mounted directly on the bolts; the large bolt diameter ensures low surface pressure.

To improve their sliding properties, the planetary wheels are impregnated with synthetic oil. In order to be able to transmit the highest possible power, gears with a very large wheel width are installed in all Optimax transmissions. This minimizes surface pressure and hence wear on the tooth flanks despite the high torques, which in turn results in a long service life.

The design also contributes to the resilience of the transmission. Despite the small edge dimension, a very large ring gear diameter was realized, as the four axial fastening screws are placed in the corners of the square. (Graphic | ebm-papst)

Another special feature of the transmission series is the high torques. The medium variant, for example, offers peak torques of up to 150 Nm with an installation edge dimension of 63 mm and a length of just 102 mm in the two-stage version. Even high radial loads caused by toothed belts or eccentrics, for example, are not critical.

The output stage has a very rigid design with two large ball bearings and can thus withstand up to 500 N radial load in nominal operation with a maintenance-free life expectancy of up to 10,000 hours. Thanks to the flat seals used, the transmissions meet the requirements of protection class IP54 as standard and are thus ideally equipped for industrial use, especially since the deliberate omission of helical gearing means that they also offer an impressive price/performance ratio.

Small edge dimension, finely graduated reduction ratio

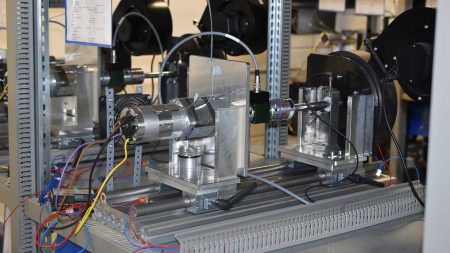

Put through its paces on the test stand. (Photo | ebm-papst)

The design also contributes to the resilience of the transmission. Despite the small edge dimension, a very large ring gear diameter has been achieved because the four axial fastening screws are placed in the corners of the square. The two flanges engage positively in the gear teeth of the ring gear, thereby ensuring both the alignment of the components relative to each other and the torque support under the housing components (intermediate flange – ring gear – housing flange). The function of the axial screws used is reduced to bracing the housing parts against one another. A nice side effect is that the fastening is easily accessible and there is no complex pinning that cannot be dismantled.

The finely tuned reduction ratio range for all three variants in the single-stage range extends from 3:1 through 5:1 to 9:1. The two-stage versions are available with reduction ratios of 9:1, 15:1, 25:1 and 45:1. The transmissions have a modular design; the seven reduction variants are implemented using three individual reduction ratios. Application-specific adaptations can also be carried out quickly for corresponding quantities.

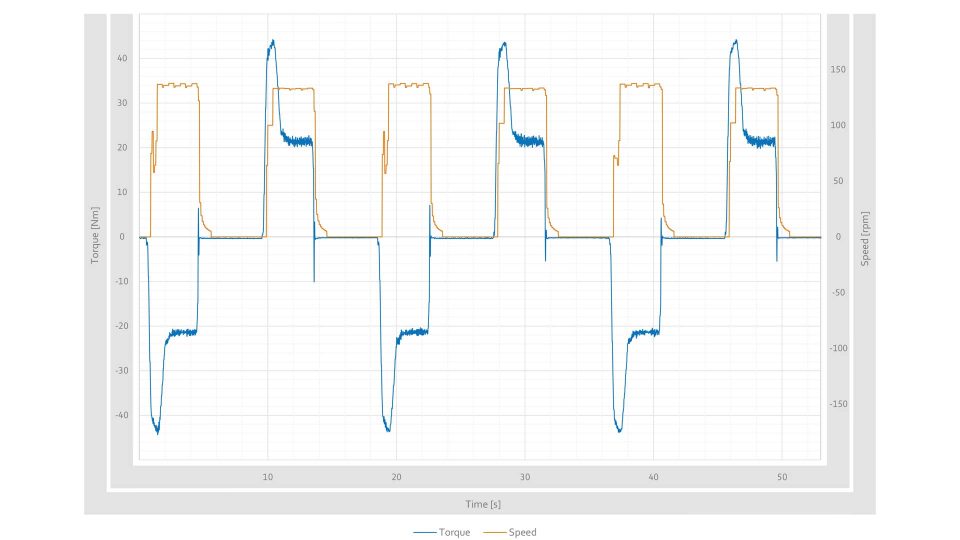

Suitable for continuous operation or for highly dynamic applications

The transmission series has been successfully tested in both dynamic cycle operation and continuous operation in an extensive product validation. This guarantees reliable operation in both modes of operation: continuously running on belt conveyors, for example, or when used in rapidly accelerating shuttle vehicles. In the latter case, the user can benefit from the high dynamics in concrete terms, as the saying “time is money” is particularly true in the intralogistics industry.

Designed for high dynamics and continuous operation. (Graphic | ebm-papst)

The Optimax series, which is now available in the modular drive system, can be combined with all ECI, BCI and VD/VDC motors. Together with the appropriate control electronics and braking and sensor modules, customized drive solutions can thus be put assembled from a single source, for example in the online portal. Several thousand variants are possible in total. Defined preferred types are ready for shipment within just 48 hours, making them available for sampling exceptionally quickly.

Leave a comment