Spurred on by increasing demand from industry, the design of the gearing components of the crown gearboxes and their manufacturing technology have been steadily improved. Combined with state-of-the-art EC motors, this creates compact and robust drive systems that effectively deliver power “round the corner” even in confined installation conditions. They are typically used in strapping machines as well as in automated transport and shuttle systems, gate and cabinet drives, and in operating tables as a sliding aid.

A new approach to crown gearboxes

When it comes to angular gearboxes, bevel gears or worm gears still spring to mind first for most people. However, there are always disadvantages when these are used, as worm gears have an offset between the input and output shaft as a matter of principle and work at comparatively poor efficiency levels, so that the motor unit of the drive unit often has to be dimensioned larger.

Bevel gears are usually limited to a reduction of max. 5:1 and are therefore also usually not the ideal choice. Although their efficiency levels are very high, both the manufacture of the gearing components and assembly, especially the alignment of the gearing components relative to one another, is comparatively complex, something which is, of course, reflected in the price. Anyone looking for an especially economical and efficient angular gearbox should therefore turn to crown gearhead technology.

High efficiency with large reduction

If you take a closer look at the design of the various angular gearboxes, you will understand quickly why crown gearboxes are a good solution for many applications. The gears of bevel gears have a conical shape. The gear function is only perfect if the center lines of the bevel gears intersect precisely at one point. As a result, simply the thermal expansion during operation alone can impair the function.

Worm gears are less sensitive, but in their case the direction of the force flow is very unfavorable. The torque results primarily in a tensile or pressure load on the worm pinion. Since the pinion slides on the worm gear, up to 2/3 of the input drive energy is converted into heat, depending on the reduction. The motor and the transmission must therefore be dimensioned larger than actually necessary to achieve the desired power. In addition, the axial load on the worm gear has to be absorbed by the correspondingly dimensioned axial bearings.

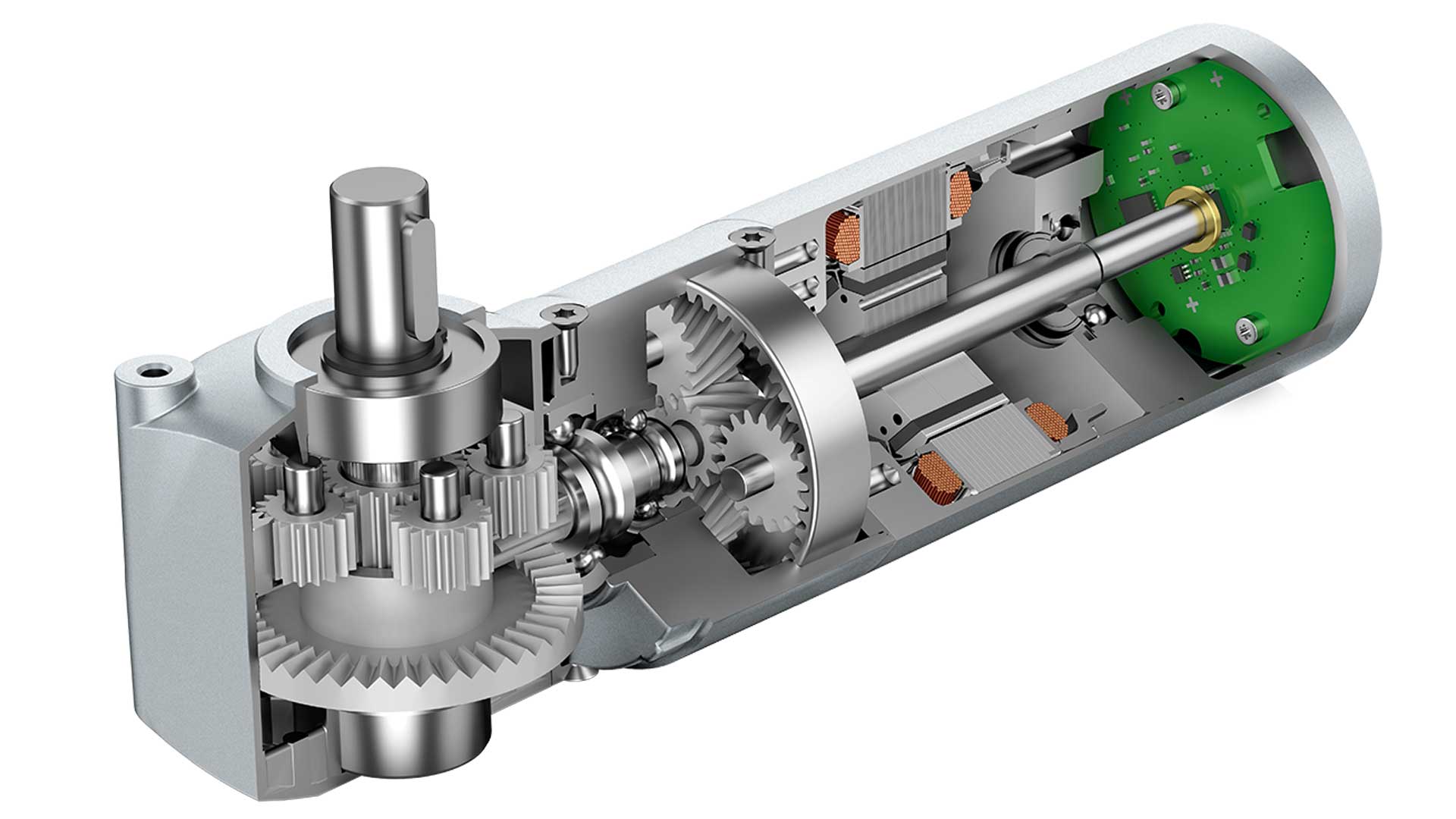

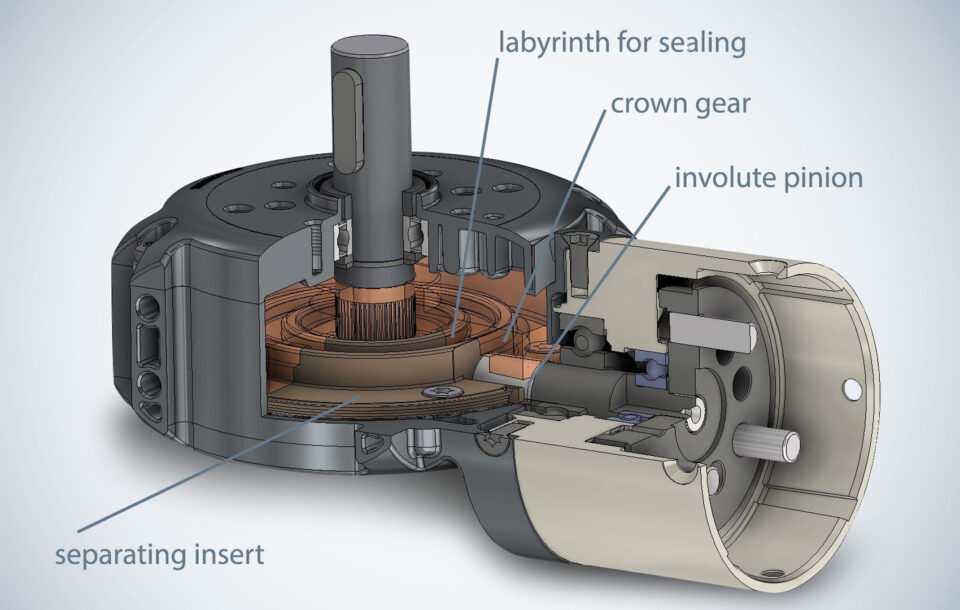

With the EtaCrown and EtaCrownPlus crown gearboxes from the ebm-papst modular drive system, this is different (Figure 1): The involute drive pinion is cylindrical and the contact between the pinion and the output gear is a roller contact; hardly any friction losses occur. Efficiency is therefore in the range of 90% even at high reductions, making the motor power almost fully available for the drive task. 10% power loss compared to up to 75% for conventional worm gear designs (depending on the reduction selected) is an enormous potential for savings even for small drives. In addition, the drive motor can often be designed on a smaller scale, saving installation space and costs.

Optimized gearing technology and patented lubrication

Crown gearboxes of various sizes cover reductions in the single-stage range up to 10:1, two-stage to 113:1 and three-stage to 289:1. The transmissions meet extremely stringent requirements here. Together with the Institute of Machine Elements (FZG) at Technical University of Munich, ebm-papst has conducted extensive research into all aspects of gearing technology as part of a sponsored project (Bavarian Research Foundation: AZ-1379-19; administrator: J.-F. Hochrein).

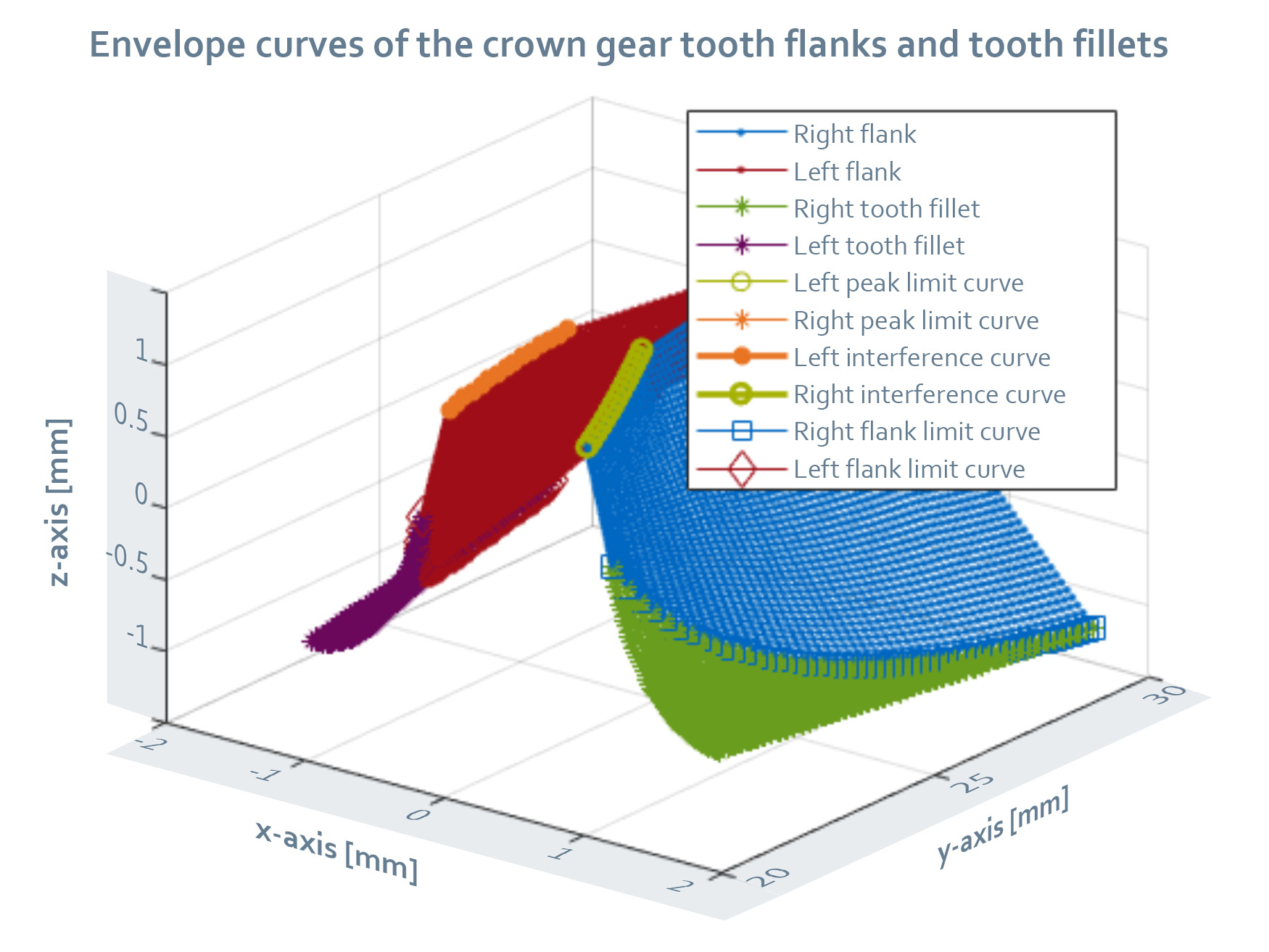

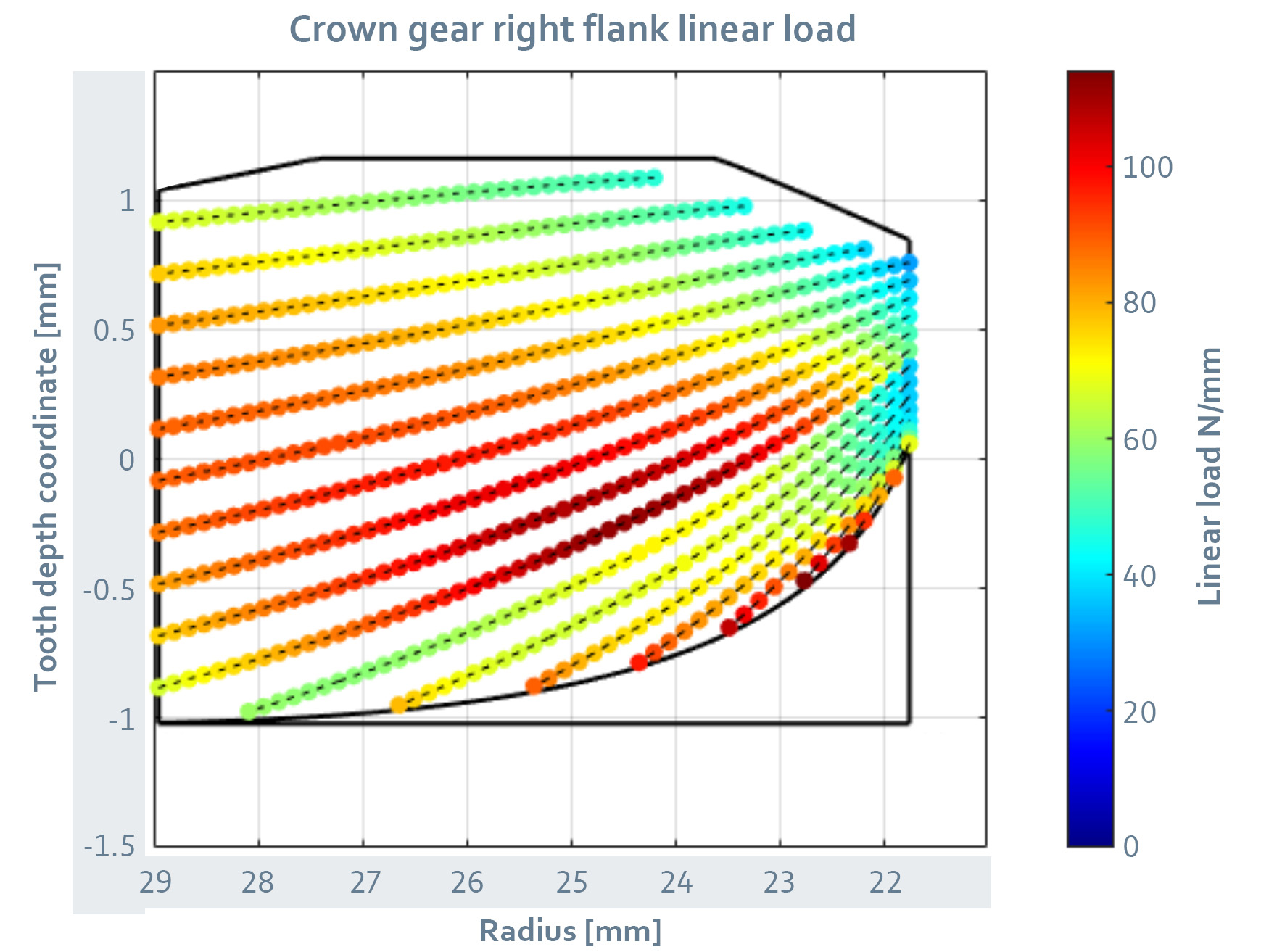

In this context, software has been developed that can be used for the first time to realistically calculate parameters important for design, such as geometry determinations and gear contact analyses under load.

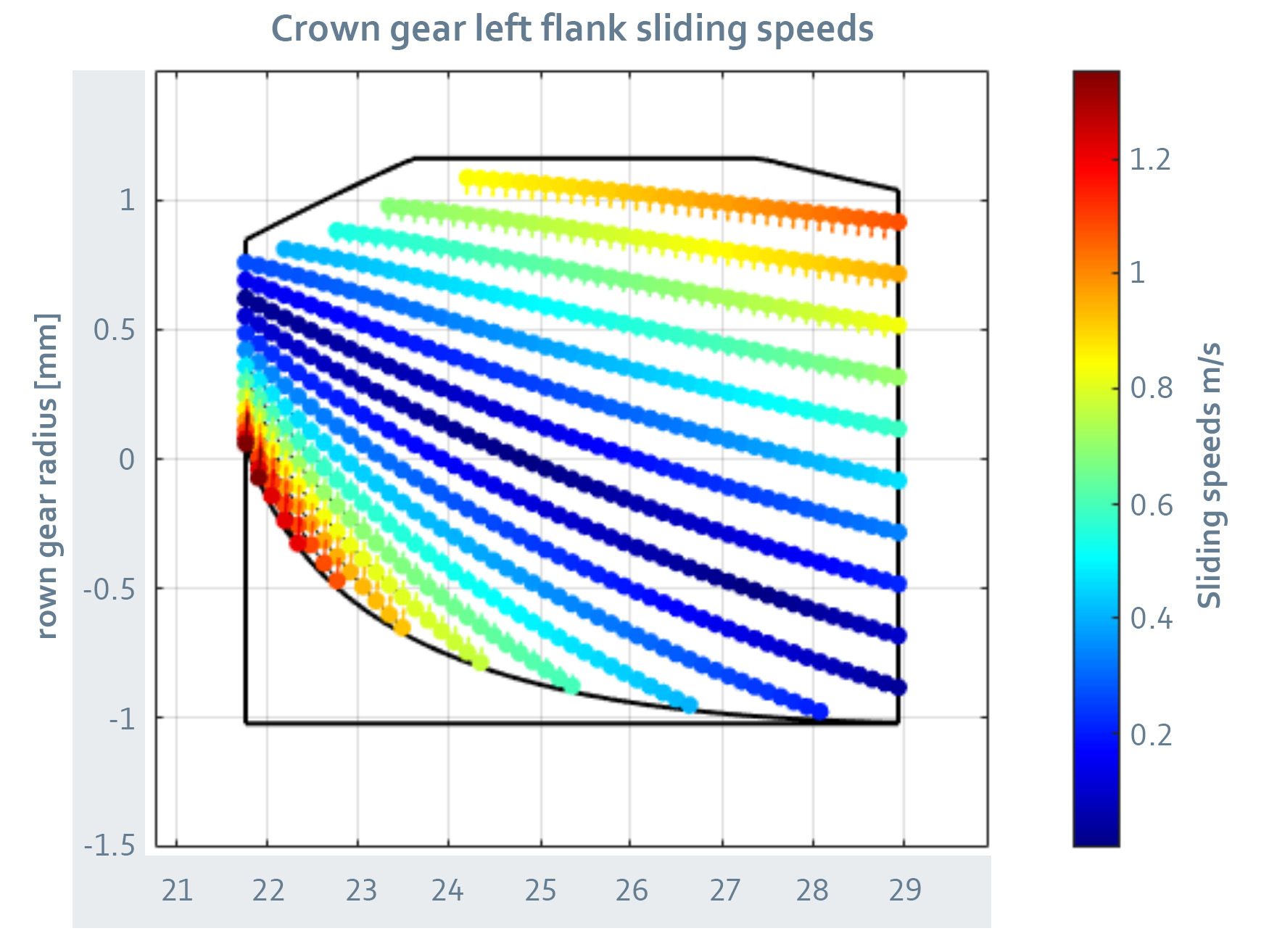

Envelope curves, for example, reflect the geometry of the crown gear flank and their boundary ranges (Figure 2) or the linear load (Figure 3) shows the force standardized to millimeters on the flank line of the crown gear tooth. The sliding speeds (Figure 4) indicate how high the rolling speeds are at the crown gear flank. The values are validated on high-performance test stands and ultimately help to optimize production.

Improved lubrication

Lubrication has also been improved. In transmissions, there is usually the problem that the lubricant from the gearing areas of the transmission gears is gradually displaced and accumulates in adjacent areas. As a result, the gearing is not optimally lubricated over the service life, which can lead to excessive or premature wear.

This has now been prevented during the further development of the crown gearboxes, as a patented separating insert in the housing keeps the lubricant where it belongs, namely at the gearing of the gears (Figures 5 and 6).

Drives for packaging technology and intralogistics

Typical applications for the versatile angular gearboxes are in packaging technology and intralogistics, for example in automated transport systems (AGV, automated guided vehicles), mobile robots, and shuttles (Figure 7). High transmittable torques, durability, and compact dimensions are points in favor of using a crown gearbox.

As the motor with drive pinion and the output axle are in one plane on the EtaCrown, the transmission can also be installed mirror-inverted without any problems, which reduces storage and simplifies logistics.

Crown gearboxes are suitable for many other applications. In addition to the high efficiency levels, typical reasons for using them are the high transmittable torque and the lack of self-locking.

Door and gate drives

In the case of barriers and access monitoring systems, for example, in an emergency, the transmissions can be turned back manually even in the event of a high reduction without the need for components for decoupling to protect the drive against damage. Due to the offset-free design, the motor-transmission combination can also be integrated easily into door profiles (Figure 8). There are no motor protrusions. This avoids recesses or additional spacers for bridging gaps. The symmetry in the transmission design makes versions for left or right stops unnecessary. The brake can be mounted directly on the drive shaft or, as usual, on the B side of the motor, simplifying the design and making the drive system more compact.

Applications in medical technology

In medical technology, crown gearboxes excel in terms of their high reliability, smooth operation, and low heating. They can be used as a sliding aid in operating tables, meaning they can be moved without motorized assistance. EtaCrown and EtaCrownPlus are part of the modular drive system from ebm-papst and can be combined with all DC and EC motors as well as brakes and encoders. Customized complete drive solutions from a single source with perfectly matched components can be combined easily in the online portal; thanks to defined preferred types, selected drive configurations are ready for shipment within 48 hours, which means that sampling, for example, can be done very quickly.

Leave a comment