InMotion’s racing car is a revolution, which is why it is also called Revolution – with complete self-confidence. It accelerates from 0 to 100 kilometers per hour in 6.5 seconds and its maximum speed is 297 kilometers per hour in simulations to date. A specially developed battery pack consists of 30 modules, each with 12 cells, and has a total capacity of 57.6 kWh, and it supplies the racing car with the energy it requires. Thanks to a sophisticated cooling system, this battery pack can currently be charged in just 12 minutes. The new AxiEco fans from ebm-papst help to achieve this.

The aim: The Revolution will be full charged within 7.5 minutes.

InMotion is a student racing team and unites 15 students from the Eindhoven University of Technology and the Fontys University of Applied Sciences. They work together on electric racing cars at the Automotive Campus in Helmond. To achieve this, they have put their studies on hold for a year. When the year is over, new car enthusiasts will join in.

Tinkering on electric cars – not just for motor sport

The time at InMotion is an exciting time for all members. The focus is on researching, adapting and testing the race car. The 2021/2022 team made many adjustments during the assembly, particularly to the Revolution’s suspension. One advantage of the project is that the team members come into contact with interesting companies and professions, which helps them to expand their network. Many former InMotion members are still closely associated with the project.

Tinkering with an electric car – not just for the race track. (Photo | Gerlach Delissen Photography)

InMotion is working intensively on electric vehicles’ biggest challenge, the battery. Charging time is not only a major issue for racing cars but – above all – on the regular car market: the long charging time is an obstacle for many potential buyers. The team’s aim is to make the charging process as short as filling up the fuel pump and to make electric vehicles more attractive as a result. To achieve this, they are working on the battery pack cooling system. The goal is in sight: The plan is for the Revolution to soon be fully charged in just seven and a half minutes.

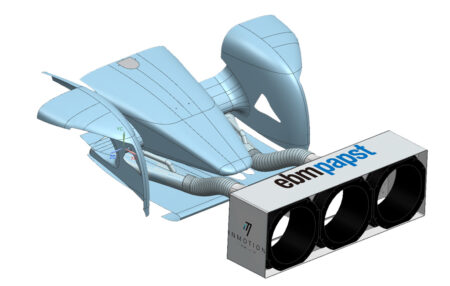

In this casing, three AxiEco axial fans from ebm-papst provide cooling for the charging process. This means that the charging process can currently be shortened to 12 minutes.

To optimize the cooling process, InMotion approached ebm-papst. After all, fans play an important role in cooling. The car’s engine and batteries are not only cooled with water but also with air. The fans have to move a lot of air, especially during the charging process, when the car is stationary. Therefore, only axial fans are suitable as they can dissipate the air through the component against the resistance: just like the AxiEco.

Reaching the goal with expert knowledge

ebm-papst is more than happy to support the student racing team with expert knowledge and hardware. This will enable years of experience in the ventilation technology and automotive sectors to be passed on to the next generation of car builders. Thanks to regular talks with ebm-papst contacts in the Netherlands, Rick van Oosterom (Sales Engineer) and Tijs de Bruin (Product Manager), InMotion receives a lot of additional information on ventilation and drive technology. The collaboration with ebm-papst brings the team a step closer to their goal.

“Revolution” electric racing car – on all tracks soon? (Photo | Gerlach Delissen Photography)

Leave a comment