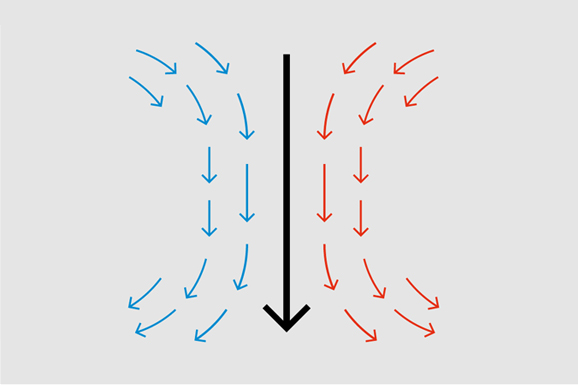

Money can be made from hot air. In the well-climatised sales room of a supermarket, customers demonstrate greater disposition to spend money and the staff absentee rate drops considerably. But if the doors are frequently opened, the warm air needs to be continually replenished to maintain the feel-good climate. This is because the natural exchange of air causes the warm air to flow out of the upper section of the door and cold air to flow in. A door air curtain system stops this undesirable exchange with a flow of warm air that helps to save up to 80 percent in energy costs.

Saving with pressure

The company Teddington from Westerwald, Germany, employs a pressure-chamber nozzle set in its energy-efficient Evolvent air curtain systems. In the pressure chamber, the airflow is compressed, distributed evenly via convex nozzle cheeks and emitted as an accelerated stream. This forms a homogeneous curtain over the complete blow-out width, which screens both the room and high door openings from the outside air. Compared to a conventional laminar system, the Evolvent pressure-chamber nozzle set offered by Teddington requires less air and offers energy savings of up to 40 percent – the unit’s own requirement for heat energy. The Evolvent nozzle devices offer this benefit for all applications.

And these are extremely varied: From screening air-conditioned rooms, through “locking in” unpleasant smells, such as those encountered in waste disposal sites, to screening large industrial portals. While a constant air curtain that is as quiet and convenient as possible is required in the entrance area of a department store, a four metre high portal to a factory hall requires a high output. ebm-papst is the R&D partner of Teddington for optimising the air-side device output. “We are responsible for everything that moves the air,” explains Winfried Schaefer, regional sales Manager, “and we supply a wide range of different products, from the axial fan, through dual inlet centrifugal blowers to backward curved centrifugal blowers.” The different performance requirements of the Teddington systems are covered in two ways: by the different sizes of the various products and by the number of blowers used in the system. The systems are modular in their design so that several blowers can be used alongside each other, depending on the output required and the width.

More EC

Teddington happily makes use of the well equipped test and experimentation research and development facilities offered by ebm-papst Mulfingen. Following extensive measurements, the entire product range was optimised at the beginning of 2009 with respect to noise development and power. “More and more end customers are discovering EC technology, which we offer as an alternative to the AC standard,” reports Schaefer. For example, if you consider a large shopping centre, in which the doors are open from morning till evening, the air cushion system fitted with EC fans quickly pays for itself. This ensures a constantly pleasant climate, and does so even more energy-efficiently and even more quietly. And that helps the customers to feel good as well.

Leave a comment