For some time now, motor and fan specialist ebm-papst has been employing a continuous improvement process in fan technology. In recent years, the centrifugal fans in the RadiPac series specially designed for use in air conditioning and ventilation units have been constantly optimized, with particular emphasis on energy efficiency, noise reduction, and handling. With the new RadiPac, it has been possible to make another decisive improvement in this successful series. The new-generation centrifugal fans work with higher efficiency levels (Fig. 1).

Higher speeds ensure a higher air flow and higher pressures, meaning that even high-pressure applications can be covered (Fig. 2). The static pressure increase that can be achieved is well over 2000 Pa. In addition, noise generation has decreased further; depending on the operating point, the noise level is reduced by between 3 and 7 dB(A) compared to the predecessor series.

Impeller: High-strength composite material, plus innovative geometry

To bring about this optimization, the impeller plays an important role. It has been developed according to the latest aerodynamic findings with its five geometrically sophisticated impeller blades (Fig. 3). A high-strength, glass-fiber reinforced composite material is used here. The complex shape is made possible by the injection molding process used. This blade geometry drastically reduces flow losses. The rounded flow contour at the blade inlet and the blade trailing edge, which tapers toward the back, contribute to this. The wavy cover plate leads to an optimal air flow rate through the impeller. The inlet ring is also made of composite material and is designed for perfect interaction with the new impeller. The sophisticated impeller geometry not only reduces flow losses, but also noise generation. When it comes to its strength, the mechanical design of the impeller also impresses. The edges on the intake and outlet sides are counter-curved, which increases the impeller’s stability.

Powerful motors for large fans

The popular RadiPac centrifugal fan product range is already used in many ventilation, air conditioning and refrigeration applications. A newly developed 24 kW EC motor has once again extended the power spectrum. The high-performance drive is installed in RadiPac sizes 710 and 800 with robust metal impeller, enabling air performances of up to 40,000 m³/h and up to 2,500 Pa to be achieved.

High peripheral speeds are therefore easily possible and, depending on the impeller diameter, they result in correspondingly high speeds. This has been proven under harsh conditions in extensive stress and long-term tests. They can be operated at maximum speed in a temperature range from -25°C to +40°C. Here, the tried-and-tested industrial composite material meets all the relevant standards, and UL approval is also available if required.

EC motors: Stronger, more flexible, and even more compact

The driving force behind the new RadiPac centrifugal fans are high-efficiency EC motors in the power range from 500 W to 8 kW. The integrated EC motors with external rotor design achieve efficiency levels in accordance with the requirements for efficiency class IE5 set out in IEC/TS 60034-30-2. For reasons of system efficiency, the drive system consisting of motor and integrated power electronics is individually adapted on each fan, and is optimized for the respective operating range. The newly developed 8 kW drive sets new standards.

The performance of the integrated electronics has been increased again, even with its more compact dimensions.

The performance of the integrated electronics has been increased again, even with its more compact dimensions. This makes the drive the most powerful in its class at present. Design and functionality have also been updated to the latest generation, and upgraded to include a configurable interface – including the MODBUS-RTU interface and integrated resonance sensor (see text in box). This resonance sensor measures oscillations and vibrations in real time. It can therefore detect imbalance due to dirt, for example, and then transmit a message before the fan is damaged.

Development of centrifugal fans

(Video | ebm-papst)

No rare-earth magnets

In EC motors with an external rotor design, the externally positioned rotor rotates around the internally positioned stator. This arrangement allows a higher torque to be achieved than with an internal rotor motor. As a result, rare-earth magnets can be replaced by ferrites (Image 4).

Numerous flexible options

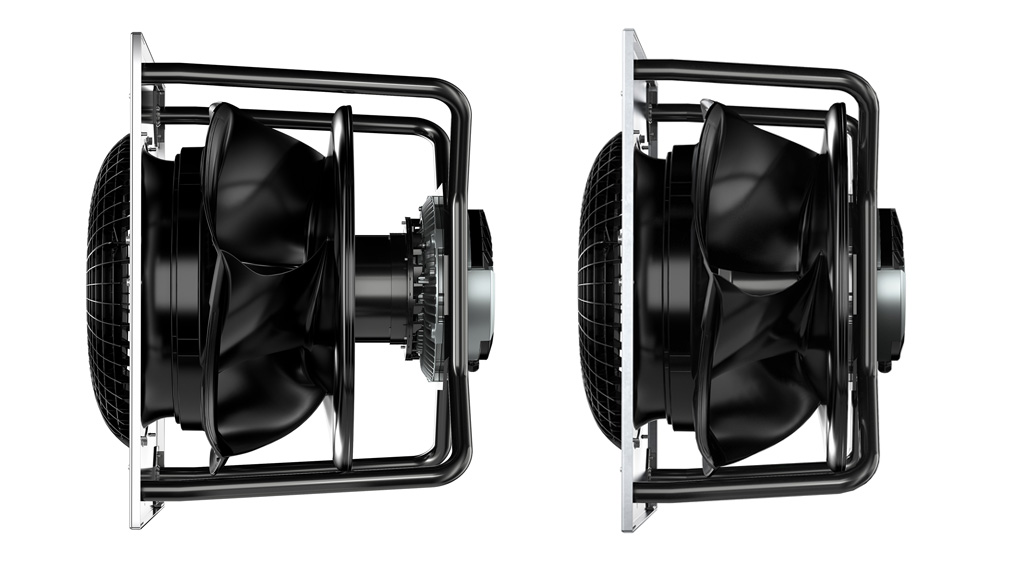

To meet the requirements of different installation situations, the new centrifugal fans are available in a standard and short version (Fig. 5). With the most powerful standard types, the impeller is attached to the motor in such a way that it has no negative influence on aerodynamic efficiency. In the short version, the motor is immersed in the impeller. These fans are more compact and are much more efficient than comparable predecessor models in spite of the slightly shorter axial installation dimensions in comparison to the standard version.

Both RadiPac versions are available as a motor-impeller combination or as a ready-to-install plug & play solution in a compact support bracket for easy wall mounting (Fig. 6). The support plates have been dimensioned to make the best possible use of space on a Euro pallet, thereby saving transport costs and improving the CO2 footprint. A completely enclosed FlowGrid air inlet grill is also available as an option. This acts as a kind of rectifier that reduces noise-generating turbulence in the inflow without changing the air performance and power consumption. It also serves as a guard grill for the intake side. The fans are then even quieter, which benefits ventilation applications as well as many others.

Automatic resonance detection for more operating reliability

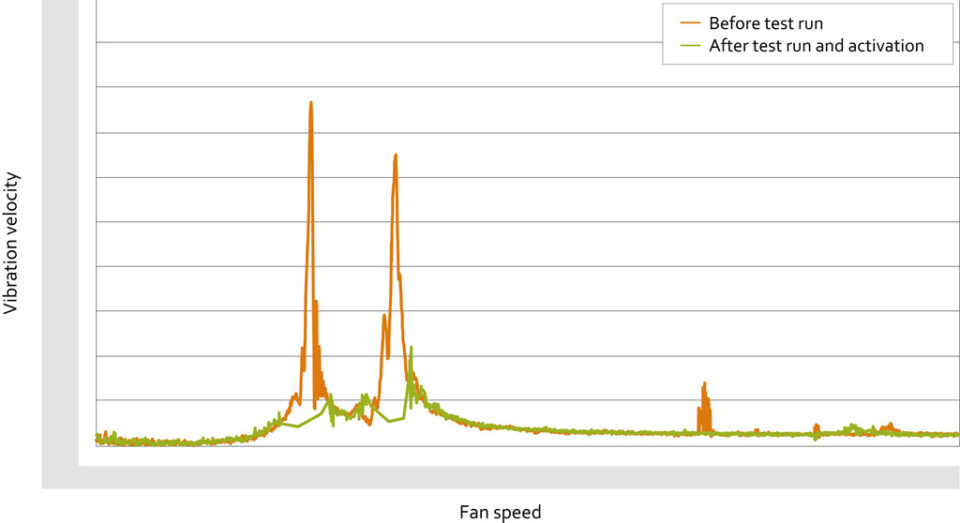

Centrifugal fans are used in a wide range of applications. Depending on the installation situation, there may be resonance in unforeseen speed ranges. If the fan is often operated in such critical ranges, the drive motors’ bearing system may be damaged, leading to fan failure. For system operators, these vibrations can be measured but are not easy to suppress. In its RadiPac centrifugal fans, ebm-papst solves the problem with an automatic resonance detection function that minimizes the effect of vibrations.

A test start-up is carried out during commissioning in which the vibration levels over the entire speed curve are recorded and analyzed. If excessive vibration velocities are detected in specific ranges, the control software automatically sets itself to “fast-forward” through these speed ranges in the future (Fig 7). In this way EC centrifugal fans can be operated without risk of damage. Operators can manually edit the software settings at any time and always have full control.

Leave a comment