Many applications require high air performance. Data centers, large industrial building complexes, hotels, residential complexes and hospitals are all typical examples. Replacing one large fan in central air conditioning systems with FanGrids containing several smaller fans that function in parallel provides many benefits in practice.

Smaller, more lightweight and simply better

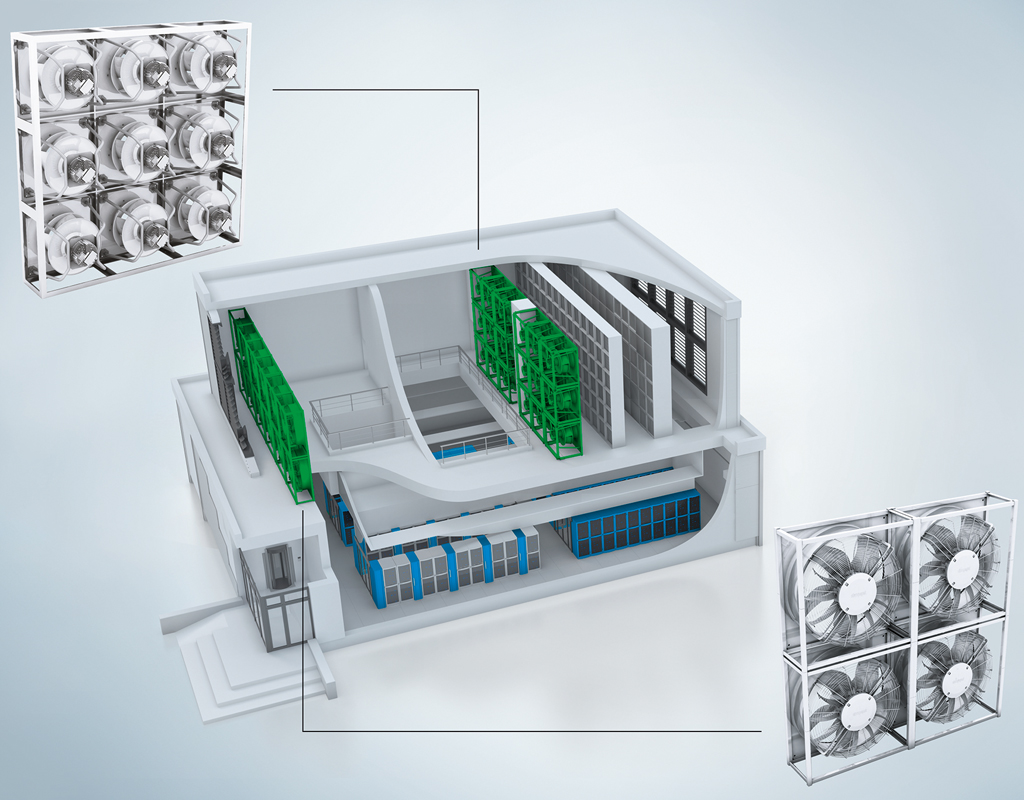

In this way, the individual fans can be stacked or arranged in rows to use the available space to maximum advantage (Fig. 1). Small fans require less installation space and are easier to handle than one large fan. Thanks to the latter benefit, transport and installation are less complicated and when a fan needs to be serviced, the system can keep running. The speed of the other fans is adjusted to maintain constant air performance. During the selection process, the relevant redundancy requirements can be taken into account.

And the air distribution is much better when several fans are used. Upstream or downstream components such as filters and heat exchangers receive a more even airflow (Fig. 2). This results in more efficient air filtering and improved heat transfer performance.

Today, the benefits of a FanGrid can be leveraged in a wide range of applications. Motor and fan specialist ebm-papst supplies FanGrid modules with RadiPac or RadiCal centrifugal fans. Several fans functioning in parallel ensure the required volume of air. Axial fans can also be used in FanGrids: today, more and more data center operators rely on “free cooling” (Fig. 3). In classical AHUs, we recommend centrifugal fans instead because they are designed to work with higher back pressure. Various sizes with diameters between 400 and 560 mm are available.

Move the slider to see the before and after comparison

Figure 2: The air distribution in the FanGrid is much better, upstream or downstream components such as filters or heat exchangers receive a more even airflow than if a single fan is used. This results in more efficient air filtering and improved heat transfer performance. (Image | ebm-papst)

Energy-efficient EC technology with convenient closed-loop control

The driving force in the FanGrid are modern EC drives with efficiencies exceeding 90%, delivering highly energy-efficient performance in both full-load and partial-load operation. They are designed for long service life and allow for stepless speed control.

The FanGrid line is rounded out by a new controller from ebm-papst that easily activates fans operated in parallel. It requires minimal wiring work: all fans are simply connected via a RS485-MODBUS cable (passthrough). Autoaddressing makes commissioning easier and individual addresses can be adjusted directly. The controller has even more to offer. It has a 0-10 V interface for positioning commands for synchronization from 0 to 100 percent, for example.

A pressure sensor on one of the fans enables volume flow control to optimally adjust air performance to changing circumstances such as clogged filters. Temperatures and speeds can be read out for individual fans or specific groups. The relevant status and failure messages can be transmitted directly to the monitoring system. Users always have an eye on the FanGrid fans and if necessary, can plan preventive maintenance on their AHUs.

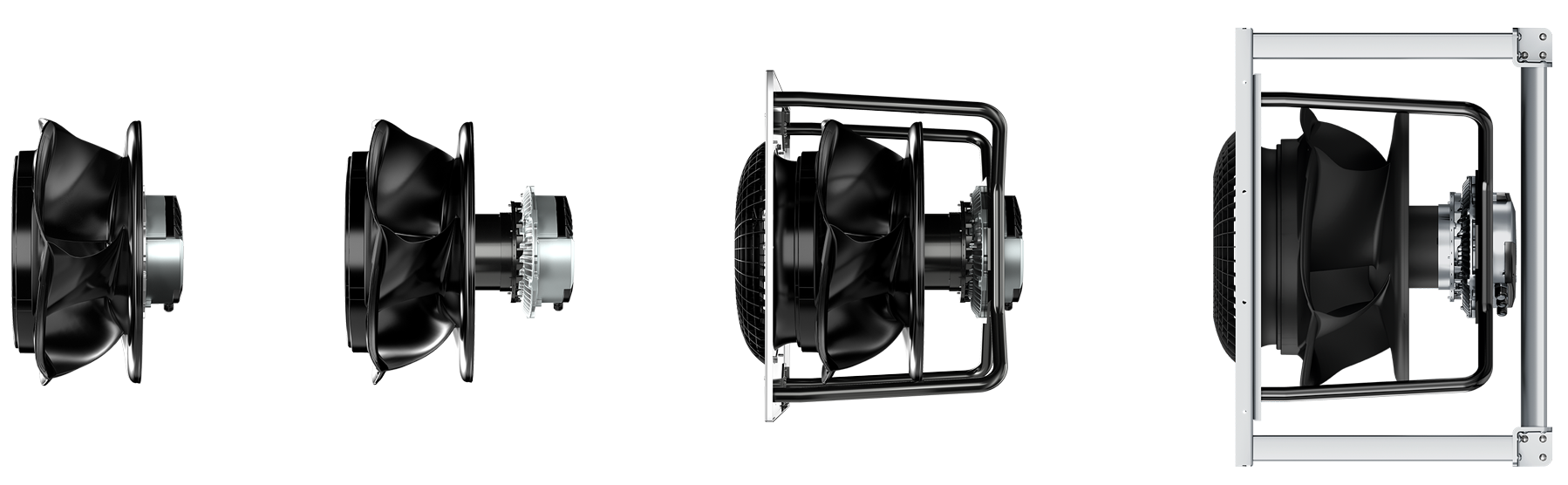

Cubes prevent installation loss

Each centrifugal fan comes with tried and tested support brackets and can be installed in a cube made of molded aluminum parts and a support plate on the intake side. During the design phase of the cube-shaped housing, a key factor was taken into consideration that is often neglected in practice: installation loss. If fans are installed too close together, they will influence one another. The rule of thumb: The greater the volume of air to be moved, the further apart the fans should be. To avoid installation loss, the FanGrid module’s cube has extra generous dimensions.

Key Advantages of FanGrids at a Glance

- Redundancy through parallel operation

- Optimal operating point

- All fans have stepless control characteristics

- Large amount of air flow

- Plug & play

- No installation losses

The cubes can be stacked or arranged in rows in the device or pressure chamber. The FanGrid also reliably separates the intake and pressure sides from each other and customers only have to close the gaps on the wall or housing with bulkhead plates. FanGrid modules come as plug & play units with the associated mounting brackets or as complete kits for direct, on-site installation. The kits consist of the fans, an air inlet grill, bulkhead plate, corner connectors, spacer profiles and bolts.

Fan selection made easy

ebm-papst has a flexible selection tool to help customers find their optimal combination of fans: The FanScout by ebm-papst is a powerful, web-based selection tool designed to support planners and manufacturers in the HVAC industry in identifying the ideal fan solution for their specific application. Accessible directly via browser without installation or updates, it offers an intuitive interface and always works with the latest product data. Users can define up to five application-specific operating points and apply a wide range of filters, including voltage, frequency, motor technology (AC/EC), installation space, and permissible noise levels. Sustainability criteria and lifecycle costs can also be factored in.

The tool automatically calculates whether a single fan or a FanGrid configuration is more efficient and considers redundancy requirements, including backflow scenarios. Up to five fans can be compared in detail, with performance data, dimensions, and acoustic diagrams clearly displayed. An expert mode provides advanced metrics such as the Fan Efficiency Index (FEI). FanScout also enables lifecycle cost analysis by combining energy consumption, operating hours, and electricity costs, and includes procurement, installation, and service costs. CO₂ emissions over the product’s lifetime are calculated to support sustainable decision-making. Results can be shared via link or PDF, and users can contribute feedback to help shape future developments. With FanScout, ebm-papst offers a reliable, efficient, and forward-thinking tool for selecting high-performance fan systems.

Automatic resonance detection for more operating reliability

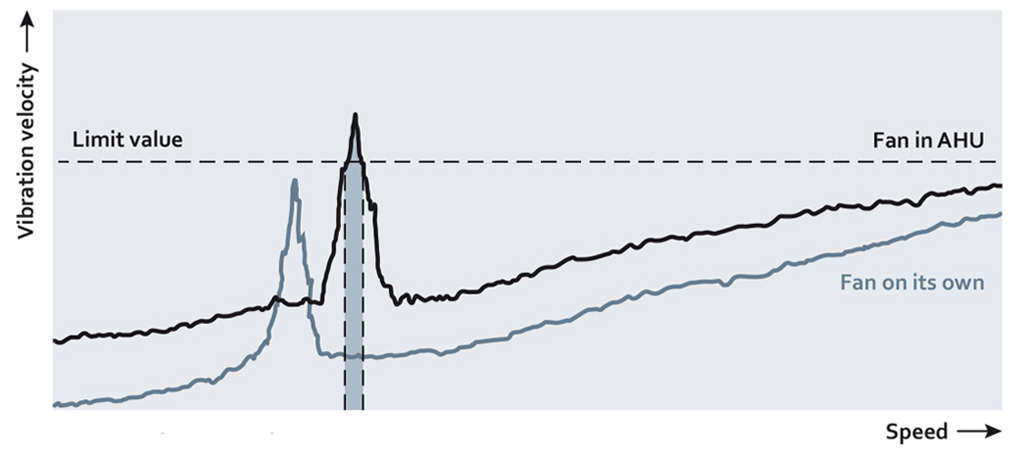

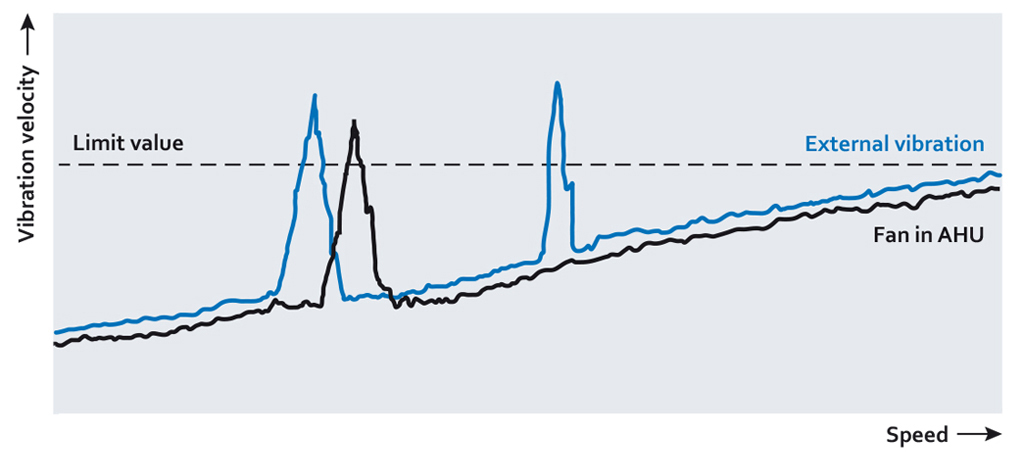

Centrifugal fans are used in a wide range of air conditioning systems. Depending on the installation situation, there may be resonance in previously unforeseen speed ranges. If the fan is often operated in such critical ranges, the drive motors’ bearing system may be damaged, leading to fan failure. For system operators, these vibrations can be measured but are not easy to suppress. In its RadiPac centrifugal fans, ebm-papst solves the problem with an automatic resonance detection function that minimizes the effect of vibrations.

Move the slider and see how the software crosses speed ranges

Figure 4: If excessive vibration velocities are detected in specific ranges (Move the slider to view the before and after), the control software automatically sets itself to fast-forward through these speed ranges in the future. (Graphics | ebm-papst)

A test start-up is carried out during commissioning in which the vibration levels over the entire speed curve are analyzed. If excessive vibration velocities are detected in specific ranges, the control software automatically sets itself to fast-forward through these speed ranges in the future (see Fig. 4). In this way EC centrifugal fans can be operated without risk of damage. Operators can manually edit the software settings at any time and always have full control.

The new RadiPac centrifugal fans from ebm-papst are perfectly suited for use in FanGrids, setting new benchmarks in airflow performance, efficiency, and noise reduction. Featuring aerodynamically optimized impeller geometry, high-strength composite materials, and powerful EC motors with integrated electronics, they deliver significantly higher airflow rates and static pressures—while operating more quietly. Available in various sizes and configurations, including compact short versions for tight installation spaces, RadiPac fans in FanGrid setups ensure uniform air distribution, high redundancy, and flexible control via MODBUS-RTU or analog interfaces. The plug & play spider-mount design simplifies installation, and optional FlowGrid inlet grilles further reduce noise emissions. With high power density and compact dimensions, RadiPac fans are also ideal for retrofit projects, enabling efficient upgrades of existing air handling units.

Leave a comment