From 2013 onwards, the ERP (eco-design) directive will enter into force for fans, This directive pursues in particular the objective of improving the energy efficiency of products and thus to realise European climate protection targets. For many electrically powered fans in use in refrigeration and air-conditioning technology, this means that they will have to satisfy the statutory limits stipulated in this directive. The result is a twin benefit: Impact on the environment is reduced and potential energy savings are felt in the pocket of the consumer. The sample calculations described below apply to refrigeration and air conditioning equipment typically found in supermarkets and they supply the necessary proof.

Since air-conditioning and refrigeration systems are operated with high duty cycles, energy savings are particularly noticeable in this area. However, there are considerable differences between applications. For example, the large condensers that are usually attached to the outsides of supermarkets have different requirements to the fans that are used in refrigeration counters and refrigerators. For each of these fields of application, “customised” energy-efficient EC fans now exist that feature outstanding reliability, maximum efficiency and low-noise performance.

Better than what is “required”

The broad product portfolio of the motor and fan specialist ebm-papst includes energy-efficient fans for practically every power range that could be used in refrigeration and air-conditioning technology. Even today they already exceed by far the efficiency values stipulated in the ERP (eco-design) directive. Thanks to the successful interaction of motor technology, electronics and aerodynamics, EC fans do not just convince with respect to their energy efficiency. They also work extremely quietly thanks to their optimised commutation techniques and the aerodynamic configuration of the impellers. And on top of everything, they also convince with their durability and reliability.

In refrigeration and air-conditioning technology, the change to modern EC technology is worthwhile on many accounts, especially as the stipulations of the directive are not only ecologically rational, they are also economically highly interesting for the user. Even on comparatively small refrigeration units, the low energy consumption can bring about substantial savings compared to conventional fans that usually work with shaded-pole motors. One example is the so-called bottle coolers that can be found everywhere where chilled drinks or snacks are sold, from kiosks or filling stations to supermarkets.

Energy-saving motors for refrigeration units and counters

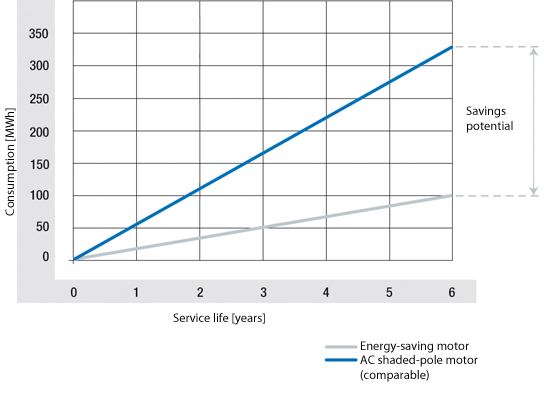

If, for example, there are two fans fitted in a refrigeration unit that are powered by conventional 30W shaded-pole motors, and if these are in operation 12 hours a day, they will consume around 262 kWh in a year. However, if the fans were to be operated with energy-efficient 10W EC motors from the energy-efficient ESM motor line from the ebm-papst product range, which boast the same air performance, this consumption would fall to about 88 kWh. There are two reasons for this: Firstly, the efficiency of the EC motor is vastly superior. At the operating point with a typical speed of 1300 rpm, the energy-saving motor has a maximum efficiency of more than 65%, allowing power input to be reduced by around 1/3 compared to a conventional shaded-pole motor. Secondly, less energy needs to be consumed from the very outset for the cooling process because less heat is lost to the environment during operation.

From the resulting difference in energy consumption of 174 kWh and assuming a price for electrical power of 11.69 euro cent/kWh (average electricity price for industry in Germany, status January 2010 / Source: VEA, BDEW), there is an immediate annual saving of about 20 euro for each refrigeration unit. The energy-saving solution thus enables payback periods of less than 12 months. That makes this investment worthwhile not just for the environment, but also for the wallet of the user, especially when the comparably long service life of the EC fans (approx. 40,000 operating hours) is taken into account.

Savings potential by the metre and straightforward conversion

Energy-efficient technology for refrigeration counters: energy-saving fans as a system solution for refrigeration counters (left), IQ motors allow a straightforward 1:1 exchange of the conventional shaded-pole motors for efficient cooling (right)

The more fans there are in operation, the greater the savings potential. Refrigeration counters are a good example. There are usually two fans for every metre in length. In a typical supermarket, there are some 100 m of refrigeration counters, making 200 EC energy-saving fans of size 200. The energy saving compared to conventional shaded-pole motors is 70%, equating to 38 MWh per year. For the environment, this means more than 22 tonnes less CO2 being produced on the basis of today’s energy mix. At the same time, the user will save more than 4,400 euro at an electricity price of 11.69 euro cent/kWh.

By no means are users only able to benefit with new installations. A conversion of existing installations is possible and straightforward. In this case, ebm-papst offers energy-efficient iQ motors, which are mechanically compatible with existing shaded-pole motors, and which have a high efficiency of up to 65% and the same installation dimensions, allowing a straightforward 1:1 exchange. Axial impellers with a diameter of 154 to 254 mm can be fitted in the same way on the iQ motor to create an energy-efficient solution. The intelligent electronics regulate voltage fluctuations so that the speed remains constant. Today, countless well-known supermarket chains are making use of this ecologically and economically rational 1:1 exchange option.

High-performance energy-saving fans for condensers and evaporators

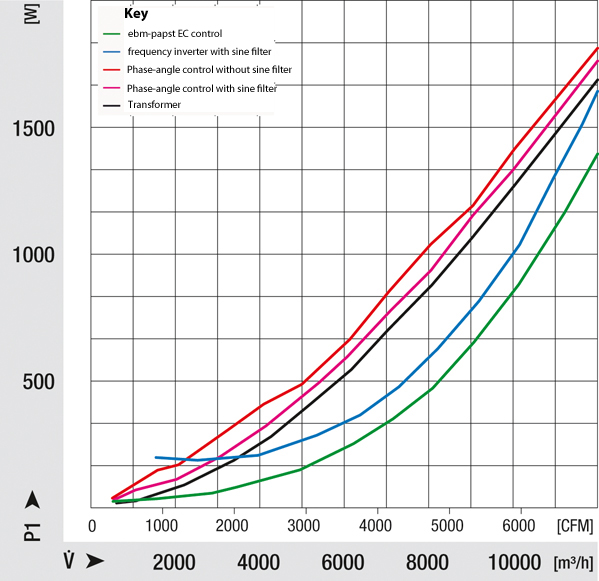

Comparable energy savings can be achieved in many other applications. For example, ebm-papst has set standards with its energy-efficient HyBlade® fans for condensers and evaporators. Thanks to modern EC technology and aerodynamically optimised vane geometry, the EC fans, which are available in sizes 172 to 990 mm diameter, convince with energy savings of up to 50% compared to AC fans. This applies not only in full-load operation, but also and especially in partial-load operation. In addition, the speed can be controlled for EC technology. In other words, it can be adjusted to the respective cooling requirements, which provides further potential savings. The result is substantially lower energy costs which are quickly felt in practical operation. The different curves illustrate the power input of controlled AC/EC motors in comparison. In all speed ranges, energy costs are vastly lower with EC motors than with voltage-regulated or frequency-inverter-fed asynchronous motors. Depending on requirements, between two and twelve of these fans are typically used in such condensers.

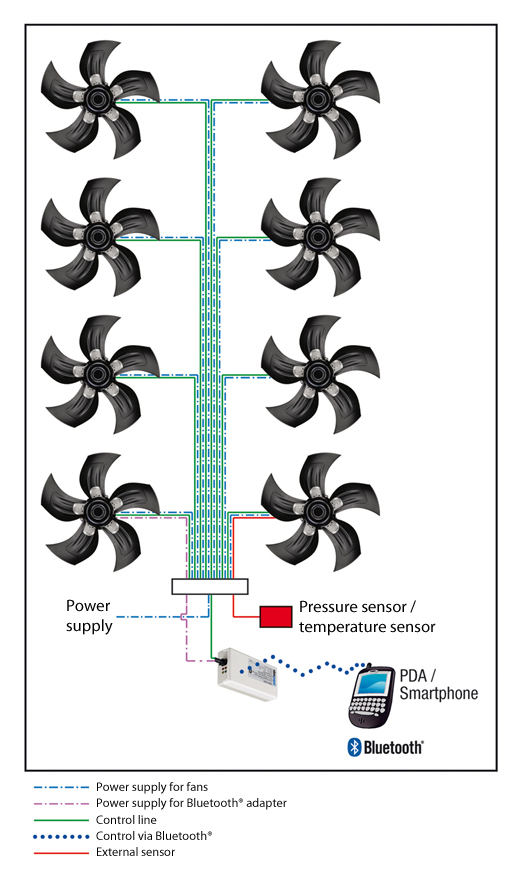

If you take a condenser with six HyBlade® axial fans of size 800 with EC technology and compare these with six AC axial fans in the same power category, each with an air performance of 11,000 m³/h at 85 Pa, the six AC fans will need a total of 5,400 W, while the EC fans will have a power input of just 3,900 W. In this instance, the EC fans consume a total of 1,500 W less energy, representing a saving of 28%. Further savings can be achieved by simply networking the EC fans via a BUS system, linking them to the higher-order management systems (see Fig. 7). Low noise levels, durability and the low weight resulting from the robust plastics used are further benefits of these axial fans. In addition, the integrated power electronics are configured for country-specific mains voltages, allowing worldwide use, regardless of whether the power frequency is 50 or 60 Hz.

Leave a comment