If you ask Adrian Heidinger what sets his company apart, he is quick to answer: its capacity for innovation. This is what has made the third-generation family company based in Mühlacker, Baden-Württemberg, a leading provider of refrigeration and air conditioning technology over the past few decades. With around 70 employees, Heidinger has made a name for itself primarily in the areas of cleanrooms and special systems and now builds systems with a cooling capacity of more than two megawatts.

In addition to energy-efficient technologies and products, Heidinger has been focusing for years on digitalization projects that offer added value for customers. “The more complex the systems and processes become, the greater the importance of digital solutions for proactive analysis and forecasting,” says Adrian Heidinger confidently. So the digitalization specialists from ebm-papst neo and Martin Ugi from Cabero, a manufacturer of heat exchangers, were pushing at an open door when they approached him for a research project on digitalizing systems.

Advantages of the digital twin at Kappler CNC

- Minimal installation work – even for existing systems

- Optimized energy consumption

- High level of system reliability

- Customized and plannable maintenance work

- Preventive service interruptions

Specifically, the Dortmund-based digital unit of fan specialist ebm-papst has developed new sensors to measure vibrations on the dry cooler and to analyze the volume flow. The data from both measurements initially flows into gateways, from where it is uploaded to ebm-papst’s epCloud. A customer with a suitable system was also found quickly: Kappler GmbH & Co. KG, a leading international manufacturer of precision components based in Birkenfeld, Germany. Innovative, open to technology and one of Heidinger’s flagship customers.

Heidinger & Kappler CNC

Heidinger GmbH

Adrian Heidinger

Heidinger GmbH

Adrian Heidinger

Kappler GmbH

Valentino Brechter

Kappler GmbH

Valentino Brechter

When Adrian Heidinger talks about his customer Kappler, he literally bubbles over with enthusiasm. No wonder, because Heidinger was able to throw all its expertise in refrigeration, air conditioning, CHP and ventilation technology at the 2,300 square meter production facility. Due to the sensitive precision components that are manufactured here, temperatures at Kappler are accurate to plus/minus one Kelvin throughout the entire production process.

One system that contributes to this precise temperature control is the jumbo recooler system from Cabero with 24 HyBlade axial fans with AxiTop Diffusor units from ebm-papst, which was installed by Heidinger in 2022. “At Kappler, we’re talking about a state-of-the-art system that meets all the efficiency requirements,” says Heidinger. “But here, too, it remains to be seen how high the added value can be with a selective evaluation of real operating data.”

Enthusiasm for precision

Kappler is a leading international manufacturing company for precision components. On the roof is the jumbo recooling system from Cabero installed by Heidinger in 2022 – a top system that meets all efficiency requirements.

„We cannot afford unplanned downtime“

Valentino Brechter explains the importance of a reliable system.

“We take our customers with us in the digitalization process”

Adrian Heidinger explains what is important in digitalization projects.

Digital upgrading in one day

The digital upgrade at Kappler was completed in a single day. The specialists from ebm-papst neo installed vibration sensors on all the recoolers. By comparing the vibrations of one recooler with those of others, or with the standard values, data analysis can be used to draw conclusions about its operating status. For Cabero, this provides important information on possible optimization potential in the design of the devices. For Heidinger, unexpected vibrations are a signal that a service may be required.

Monitoring with sensors and ultrasonic measuring devices

The current consumption is measured on every second fan of the recooler. Increased current consumption allows conclusions to be drawn as to whether, for example, the recooler slats are dirty and need to be cleaned. Other sensors measure the volume flow and the temperature in the flow and return. Here too, conclusions can be drawn as to whether the system is running efficiently. In order to keep the installation costs for the flow rates of the cooling medium as low as possible, the experts at ebm-papst neo opted for an ultrasonic measuring device that can be attached to the outside of the pipes.

“Forecasts make maintenance plannable”

Adrian Heidinger explains what the digital twin’s forecasting options make possible.

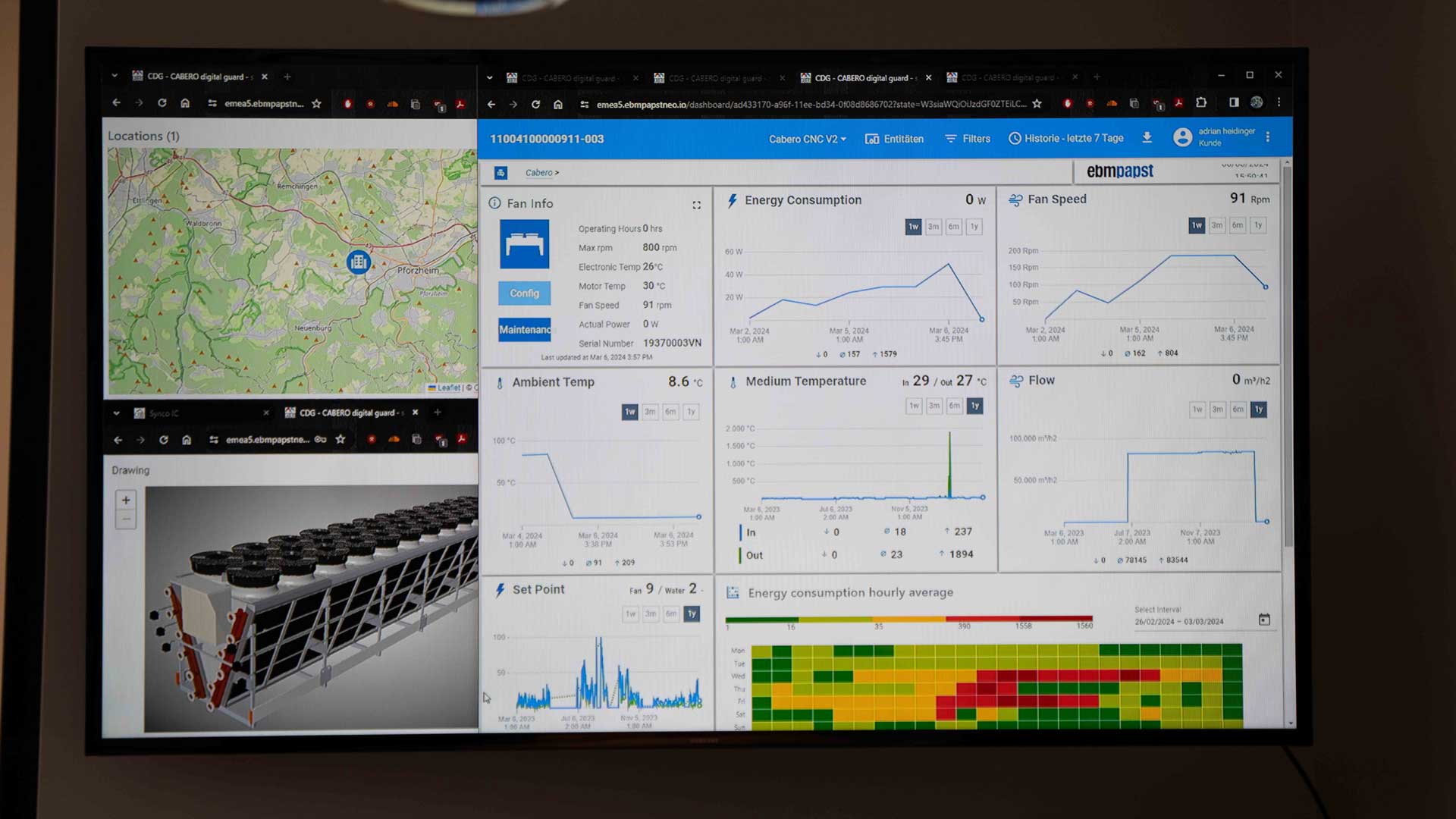

Gateways and epCloud for the digital twin

Another component of the digitalization project are the IntelliGate gateways. This is where all the data from the new sensors comes together and is uploaded to ebm-papst´s epCloud. Ultimately, recording the data from the volume flow, temperature, vibration and current consumption makes it possible to create a model of the Kappler system: the so-called digital twin. This model can be used to determine the current status of the system, making it possible to predict potential problems – which in turn enables Heidinger to react proactively to avoid unplanned downtime and service calls. The digital twin is completely autonomous and decoupled from the Kappler network. Authorized users – ebm-papst neo, Cabero and Heidinger – can analyze the data and identify optimization potential for the customer.

“Of course, the system has already supplied data in the past,” explains Heidinger. “Now, as a solution provider, we can incorporate the new data into our overall system control and process it in a way that makes it easy for us and our customers to understand and use.” At Kappler CNC, the digital twin has confirmed what everyone involved expected from its real-life counterpart: the system is running extremely efficiently and smoothly. For Adrian Heidinger, the research project shows plenty of potential for other customers: “Thanks to the minimal time and effort required for installation, we can also use targeted data analysis to determine where there are snags and where efficiency improvements are possible, even for companies with older systems.”

Data is also becoming increasingly important when it comes to determining a company’s carbon footprint. Decarbonization is key here. Large corporations are already often demanding concrete statements on the efficiency of systems and their environmental compatibility. And in future, legislators will also expect reliable figures. “Digitalization is an issue that many companies in the air conditioning and refrigeration industry are reluctant to tackle,” says Adrian Heidinger. “Research projects such as this one by Heidinger, Cabero and ebm-papst neo show the real added value that intelligent technologies can offer any company – even with very little outlay.”

Leave a comment