In terms of installation space, low weight, high efficiency, and long service life, electrically driven, gas-bearing turbo compressors are one of the best solutions for this. The newly developed oil-free CompaNamic turbo compressors from ebm-papst in the motor power range from 10 kWe to approx. 55 kWe enable variable delivery rates for different refrigerants and require significantly less refrigerant thanks to an internal volume reduction of 90% (intro image). The 10 kWe variants developed for R290 and R1234ze(E) are suitable for many areas of application. However, maximum gas purity through the elimination of oil lubrication and a wide range of applications required innovative approaches to oil-free bearing technology, aerodynamics, motor design, and power electronics. New methods for the precision machining of compressors and gas bearings were integrated for large-scale series production planned for the end of 2028.

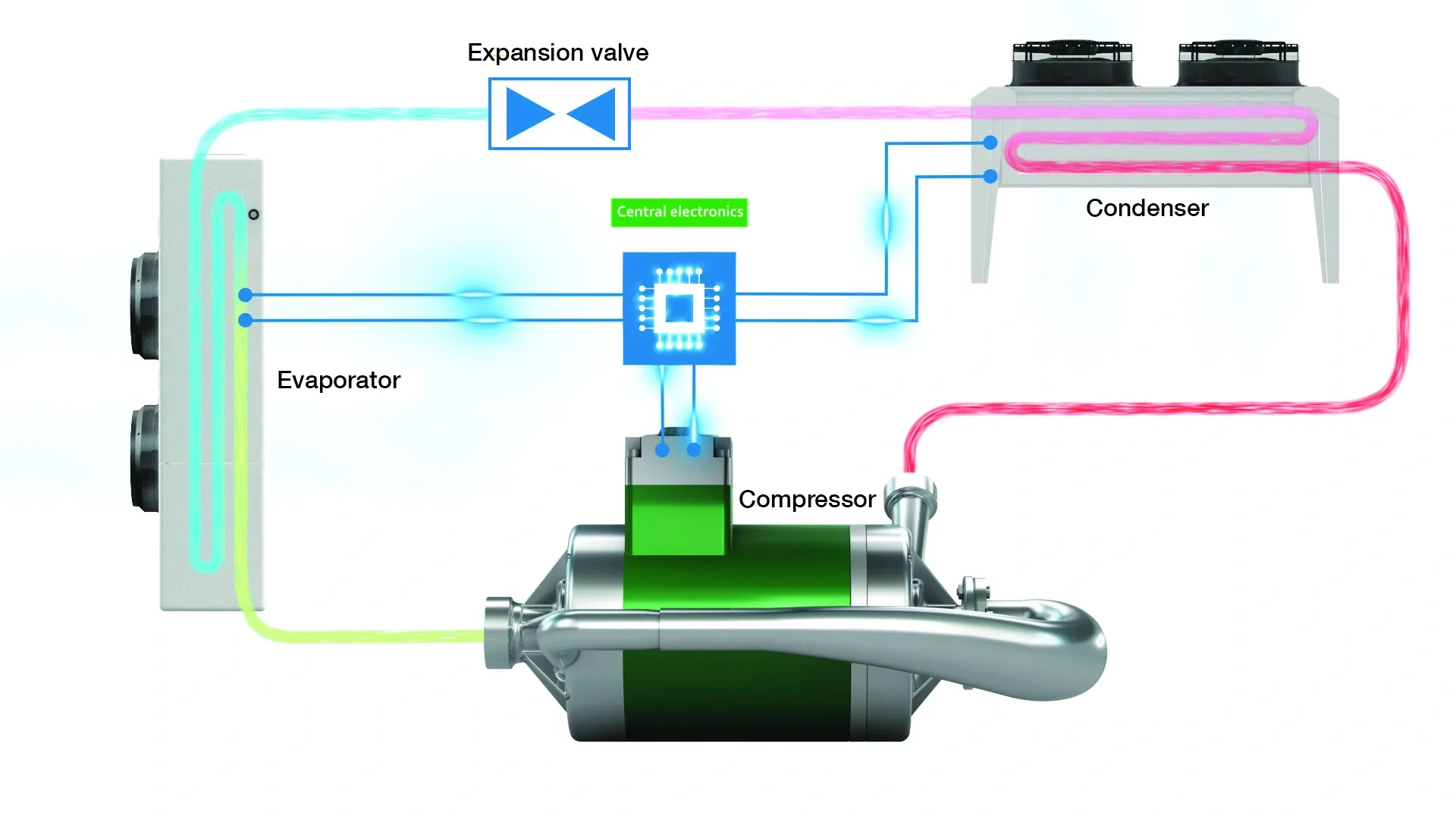

The task of a compressor for heat pumps and refrigeration technology is to compress refrigerants as efficiently as possible over long periods of time with low operating noise. Ideally, it should operate oil-free, keeping the system clean, increasing heat transfer efficiency, and eliminating the need for auxiliary equipment such as oil separators, oil sumps, and the design complexity of oil return systems (Figure 1). Depending on the area of application, the compressors and, above all, their bearings must operate with as little maintenance as possible for many years, both in continuous operation and in start-stop cycles. The end units should also be as small and light as possible, so that compact and dynamic PFAS-free compressors are in demand, which can be installed in any position without having to worry about oil return. While the drive and bearings can remain virtually unchanged for a wide range of refrigerants, the aerodynamics sometimes must be adapted significantly to the gas used.

In practice, the developers were able to achieve this by using high-speed internal rotor motors enable the construction of very compact compressors with 10 kWe at a diameter of only 130 mm and a length of 300 mm, weighing only 6 kg. At the same time, an internal volume reduction to just 400 cc in the ebm-papst P3 compressor – compared to conventional compressors with approx. 5000 cc – has made it possible to drastically reduce the amount of refrigerant required. By eliminating oil, heat transfer is improved due to the lack of surface wetting with lubricant (oil including additives) in the heat exchangers, and pressure losses are minimized. In addition, there is no oil contamination and efficiency degradation of the heat exchangers due to oil over their service life. As only pure refrigerant is in circulation, oil maintenance and oil handling equipment are no longer necessary. The perfectly balanced rotating parts result in vibration-free, quiet operation. The sound power level is around 60 dB(A). To achieve this, advanced technical solutions are required in many areas.

Aerodynamics is the key element

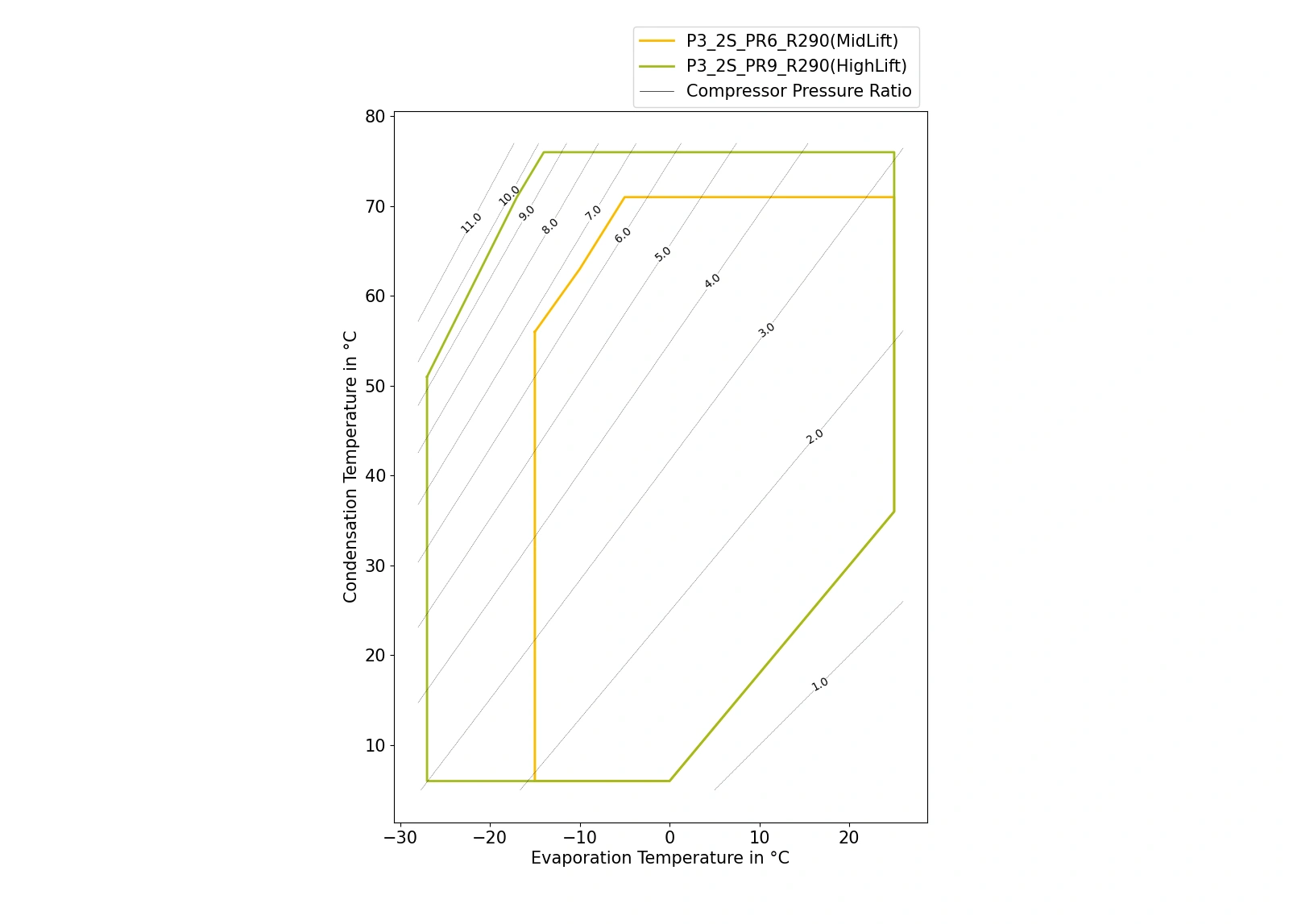

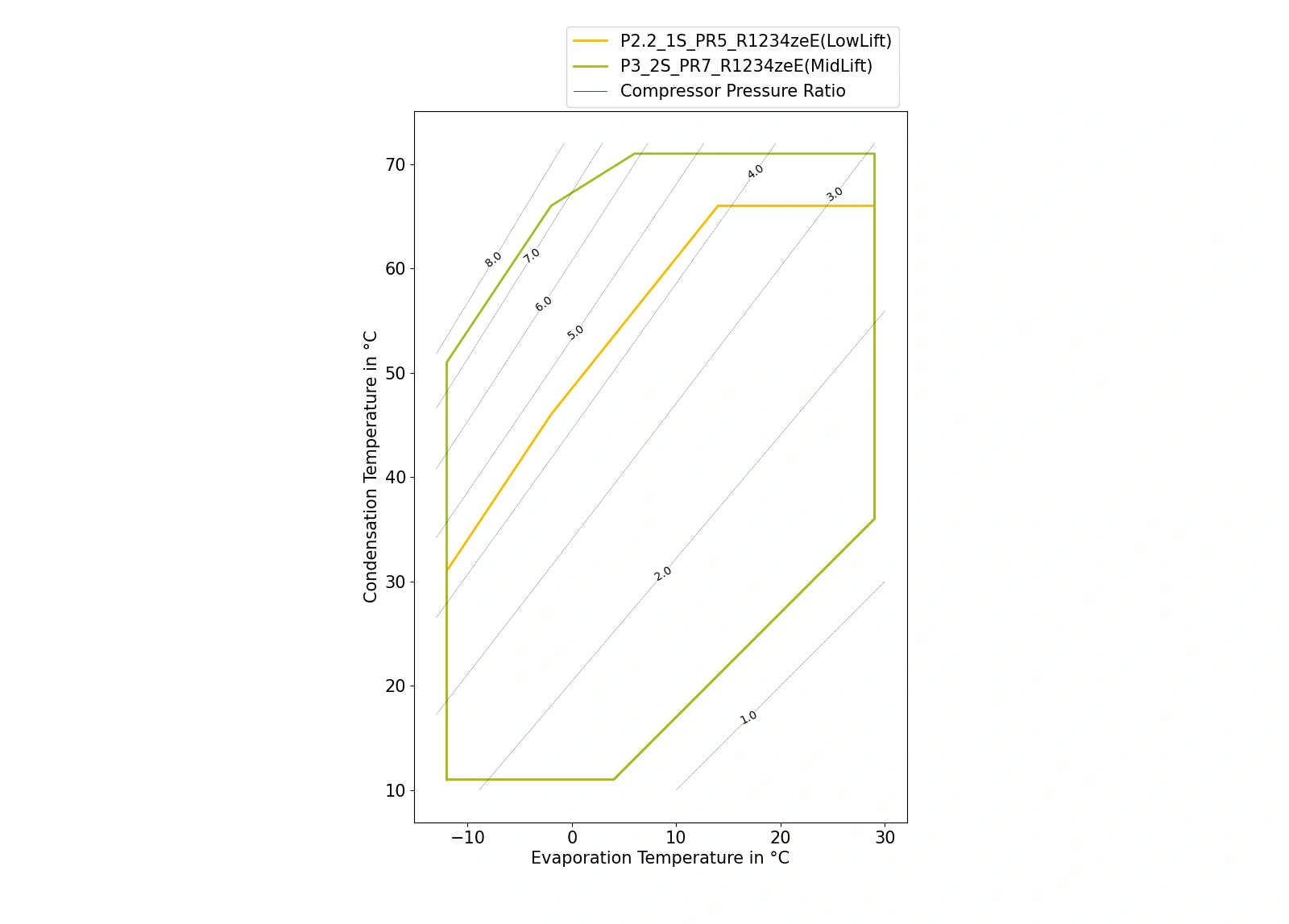

The compressor size is determined by the different requirements of the heating or cooling technology used. A compressor power of 10 kWe for the refrigerants R290 and R1234ze(E) marks the start of the product portfolio. This is particularly suitable for larger buildings or industrial applications. In order to efficiently cover the different requirements resulting from the envelope of pressure ratio and mass flow, the entire range of design options for the wheel and blade geometry must be utilized. The SCOP (Seasonal Coefficient of Performance) points from different applications are used for this purpose. In addition, especially with small impeller diameters, it is crucial to reduce the blade gap losses that occur to a technically feasible minimum. This ensures highly efficient aerodynamics.

The envelope (Figures 2 and 3) describes the operating limits. The X-axis represents the evaporation temperature, and the Y-axis represents the condensation temperature. The MidLift and HighLift variants require higher pressure ratios and therefore 2-stage solutions. A single-stage solution is sufficient for the LowLift version. After simulation, the characteristic maps were also measured, verified, and optimized in ebm-papst’s own new, state-of-the-art compressor test facility. The company’s core business in fans also provides access to a high-performance environmental testing center. Here, the compressors are subjected to long-term testing.

Bearing technology

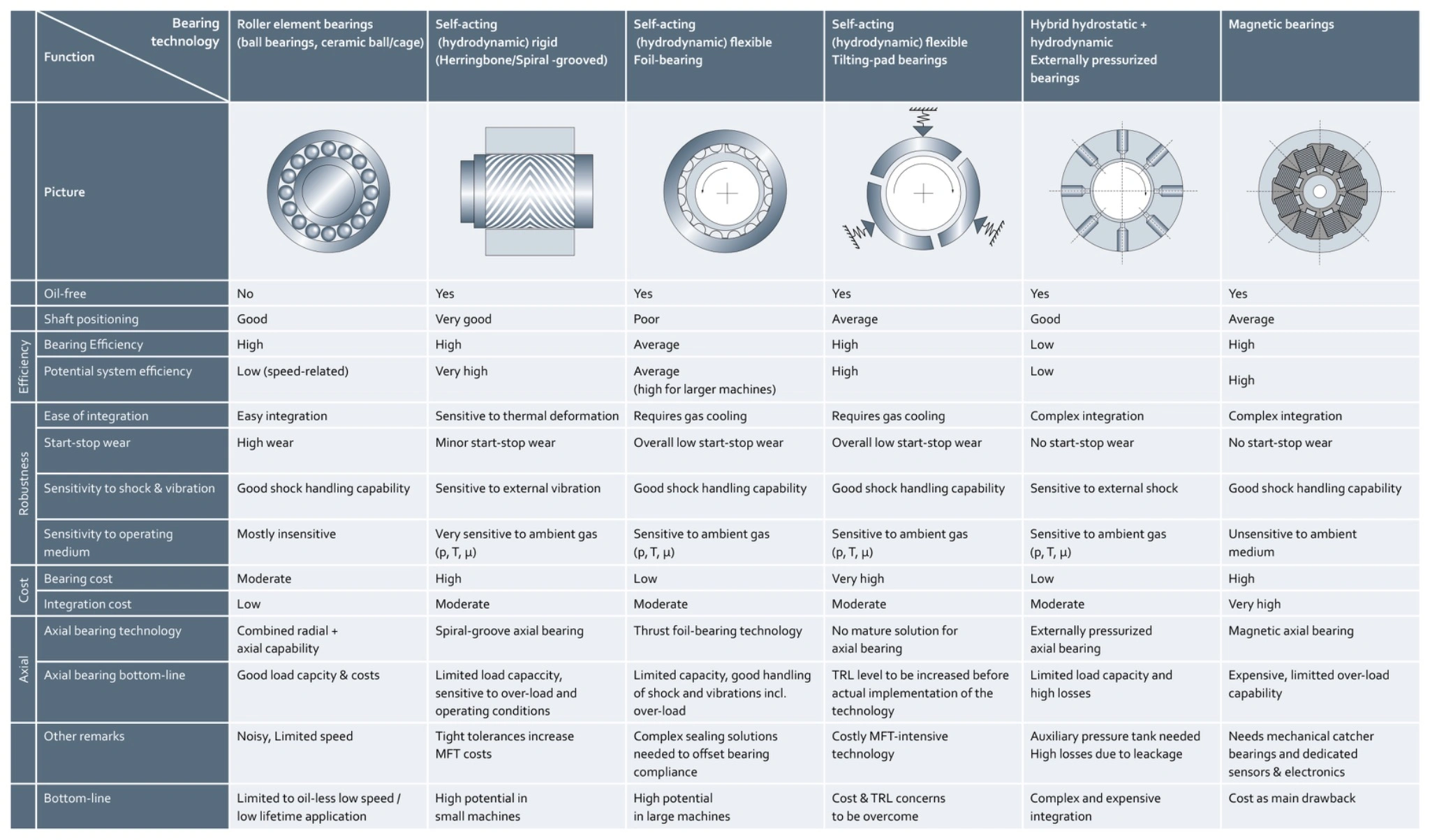

The high performance and dynamics of the units in relation to their size require a sophisticated bearing system. The table (Figure 4) shows the differences between high-speed bearing technologies, with a focus on radial bearings. Inexpensive plain and ball bearings have a short service life at high speeds and can also contaminate the gas with oil or grease. Magnetic and gas bearings, on the other hand, operate with virtually no wear. However, magnetic bearings are still very expensive, so gas bearings are a good compromise. Aerodynamic rigid gas bearings in particular enable precise positioning of the shaft compared to film bearings, allowing a minimum blade gap between the blades and volute to be set during operation for a particularly efficient flow machine. During operation, the shaft floats on a cushion of compressed working gas. Lubricants and coolants are not required, and possible contamination by additional substances is avoided. The refrigerants remain absolutely pure. A suitable choice of materials and hard coating of the bearing surfaces ensures virtually wear-free start-up and rotor run-out. ebm-papst compressors are designed for a service life of approx. 150,000 hours and more than one million start-stop cycles.

Efficient motor with compact dimensions

Motor power is defined as the product of torque and speed, which is why high power can be achieved at high speeds even with a compact electric motor. Despite their low torque, the compact, high-speed internal rotor motors deliver 10 kWe at approx. 160,000 rpm, and larger versions will deliver up to 55 kWe at approx. 60,000 rpm. However, high-speed drives require precisely matched geometry of the stator and permanent magnet rotor, as otherwise there will be significant iron, copper, and rotor losses, which are further increased by frequency-related effects. Higher voltages allow smaller copper cross-sections, but place increased demands on the winding insulation. Various cooling concepts have been developed to dissipate the waste heat generated. The same applies to the power electronics.

Power electronics for high-speed motors

The power electronics must be adapted to the operating conditions. In compressors, they can utilize the wide range of supply voltages and allow for good power scaling thanks to the modular design of the output stages. The usual mains voltages are approx. 320V to 480V 3-phase AC. The high speed of the internal rotor motors requires currents with frequencies of up to over 100 kHz for control in pulse width or pulse amplitude modulation, which the power output stages must provide reliably. All components must achieve the highest possible efficiency of more than 97% even at partial load, and the applicable standards and user specifications, e.g., for harmonics, must be complied with.

New processes for series manufacturing

The gas bearing in the high speed CompaNamic compressors requires very precise manufacturing tolerances. These can only be maintained with a special production environment and precision measurement technology. New processes are therefore necessary for the large-scale production of precision parts. The entire production process takes place at a constant temperature, i.e., in an air-conditioned environment. Instead of the conventional 3 to 4 µm, tolerances of less than 1 µm can thus be maintained. The entire manufacturing process is monitored by in-line precision measurements. It goes without saying that all component-related measured values are recorded in a database and stored with a serial number. To be able to produce large series economically despite the effort involved, production must generate as little waste as possible and must be continuously readjusted accordingly.

150.000h

Planned service life of compressors

90%

Reduction in internal volume compared to conventional compressors

160.000rpm

Revolutions per minute of the internal rotor motors

This enables the manufacture of economically efficient, oil-free turbo compressors that compress particularly environmentally friendly and natural refrigerants with very low global warming potential. The high efficiency and low operating noise protect the environment, and the vibration-free operation prevents structure-borne noise transmission into the system. This makes the new ebm-papst CompaNamic high-speed compressors suitable even for demanding applications with high requirements for smooth operation and reliability.

Leave a comment