Two air handling units (AHUs) supply a large furniture store, including a warehouse, in Dubai with fresh, cooled air. Belt-driven AC fans were used for this (Fig. 1). The control concept implemented on site allowed for one of the two AHUs to always be in operation at full load for six months, while the other AHU was out of service at the same time. After six months, the other AHU took over the supply of fresh air again. Since the AC fans could only ever operate at a single speed, a lot of energy was wasted, above all when there were few people in the furniture store, as more fresh air was supplied than required.

There was only one solution that could be implemented both economically and within the required time for these problems. This was equipping the AHUs with new, efficient fans and optimizing the control system in line with requirements. Jon Davies was awarded the retrofit with his company Qey Energy Solutions, which has its headquarters in Dubai. In this project, they collaborated with Johnson Controls to develop a suitable control concept.

A complete solution for the AHUs

There are generally two challenges for retrofits: time and space. This was also the case in this project. Qey calculated four days for the conversion of an AHU. If the other unit failed during this time, there would be no more fresh air supply for the furniture store. This time pressure meant that the new fans needed to be installed quickly and smoothly. The new solution thus had to be installed in the AHU so it saved space and was as ready in advance as it could be.

This is why the “MatrixAir+ EC” fan package from Qey was used. This complete solution consists of four products: EC fans, fan connection boxes, fan bulkheads, and control panels. For the first component, EC centrifugal fans from the RadiPac series from ebm-papst (Fig. 2) were chosen, as their compact design and ready-to-install plug-&-play design make them easy to install. A total of 26 RadiPacs were installed as FanGrids in the AHU intake and exhaust sections.

FanGrid ensures operational reliability

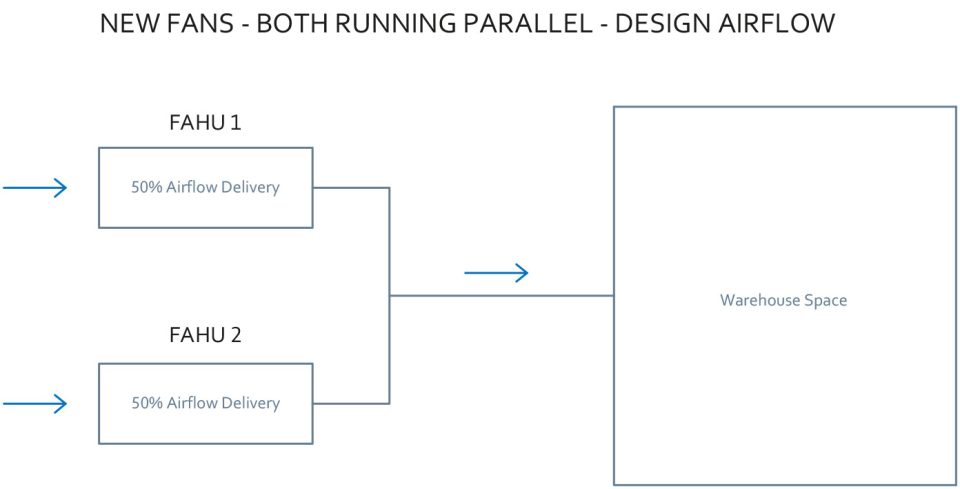

A FanGrid consists of several small fans arranged next to or above one another and operated in parallel (Fig. 3). The redundant design increases the reliability of the entire system and ensures operational reliability. If one fan fails, the other EC fans compensate for the missing air volume. Even if an entire AHU fails, the remaining AHU is still able to independently meet the complete fresh air requirements.

This offers the necessary reliability, particularly in large plants and especially hot regions like Dubai. In addition, it is no longer necessary to operate an AHU constantly at full load while the second serves as a back-up. The current fresh air requirements are distributed evenly across both AHUs (Fig. 4).

The fans are operated at partial load, which has a positive effect on the service life. Another advantage of this type of setup is that the flow through upstream and downstream components, such as filters or heat exchangers, is more uniform. This results in more efficient filtering of the air, as well as better heat transfer performance, and thus a reduction in operating costs. Several small fans may also require less space and are lighter than one large fan, making replacement easier.

EC motor saves energy

The main aim of the retrofit was to save energy. This can be achieved through two mutually beneficial measures: replacing the fans and reworking the control system. Those involved in the project in Dubai decided on both to exploit the greatest possible energy saving potential. Significant savings are already possible thanks to the high efficiency of GreenTech EC motors of over 90% alone.

They are also infinitely adjustable, ensuring demand-based operation – so between 0 and one hundred percent instead of just on and off as is the case with AC fans. This results in significant savings potential, as the power consumption increases or falls in line with the speed to the power of three (P~n³). This means that if the speed is reduced by half compared to the nominal speed, the required power consumption is reduced by a factor of 8 and is therefore only 12.5% of the rated output.

However, if half of the number of AC fans is switched off and the other half still operates at full load, only 50% of the power consumption can be saved. The reduction in speed also leads to significant advantages in terms of noise emissions. Thanks to the wide optimum efficiency range of centrifugal fans, they work with as little power consumption as possible at just about every operating point.

Demand-based control

After replacing the fans, they moved onto the control system (Fig. 5). The furniture store’s ventilation system already had a building management system, but the aim was to develop a time-based strategy. For this purpose, occupancy data was evaluated, the number of visitors (which varies throughout the day) calculated, and the associated air flow requirements determined depending on the time.

This data was then used to program the “Scheduled Mode,” in which a controller specifies the fan speed at certain times based on an internal schedule. Both AHU controls work in parallel to always convey 50% of the required air flow depending on time. A prerequisite for the control system was also that the fans could communicate with the building management system. Thanks to the integrated control electronics of the RadiPac EC fans with RS485/MODBUS RTU interface, this was no problem.

What the Tech: How will a retrofit increase the efficiency and durability of your ventilation unit?

What is a Retrofit? And why could it be the right choice for me?

Find the answer here: simple, understandable and with a bit of humor!

Communicating with the building management system was particularly important for documenting operating data. Firstly, this enables the actual savings to be checked and, secondly, the control system to be optimized. If you evaluate data, you have more reliability as problems can be identified quickly and negative consequences can be prevented at an early stage.

A differential pressure measurement is easy with the RadiPac, as it has a pressure tap for connecting a differential pressure transmitter. This enables conclusions to be drawn about the conveyed air flow, and this can be monitored alongside many other important fan operating data. This also makes it possible to determine the savings resulting from the retrofit. In this case, an impressive 79%. The Qey project team also expects a return of investment of just 3 years.

The 5 most common questions about retrofitting

1. When is a retrofit worthwhile?

If a ventilation system is 10, 15 years or older, an upgrade makes sense in many cases. Switching to new EC fans saves a significant amount of energy. Other advantages include durability, saving space, and operational reliability.

2. How do I approach a retrofit?

Retrofit experts provide support in recording performance data, work out possible concepts, and can provide a rough overview of costs. They look at the purpose of the system and at which point it should be operated optimally.

3. How does a retrofit work?

The first step is a current measurement of the current status. Then it is time to select the right fan. In this process, the entire system, environmental factors (altitude, temperature, etc.), options for electrical integration, and mains supply must be taken into account. During installation, attention must be paid to the seals in the ventilation room. The new state is then measured at the end.

4. What payback period can I expect?

This cannot be answered on a general basis, as the local energy costs are a significant factor. But even with the low energy costs in the United Arab Emirates (compared to the situation in Germany, for example), it was possible to achieve a short payback period of just 3 years due to the great savings achieved.

5.How do these savings come about?

Thanks to the EC technology, optimized aerodynamics, and demand-based speed control.

Leave a comment