When the drive belts suddenly stopped working, Peter Halblaub knew he was in for a real challenge. It was a warm day in October 2019, and he was standing in front of the ventilation system that had provided the Neckarsulm shopping center with fresh air for almost 30 years. At least, that was what it was supposed to do. But at this moment, everything had stopped working. “We had replaced the drive belts not long before, but now the system had stopped again,” recalls Peter. He is the facility manager at Sauter FM GmbH, and is responsible for the shopping center building and its technical systems. “It was clear to us that the system would break at some point, but it surprised us that it went so quickly.”

He contacted building technology specialist Wolfgang Stickel, who confirmed his worst fears: “The axle bearing was completely faulty. As a result, the fan wheel had dropped and eaten into the housing.” He ruled out the possibility of reassembling the axle layer-by-layer due to the enormous material abrasion. What was more, the entire system simply no longer met modern-day requirements. “When our ventilation was installed, energy efficiency wasn’t a major concern. That’s different now,” says Wolfgang. That made it clear that a new system was needed.

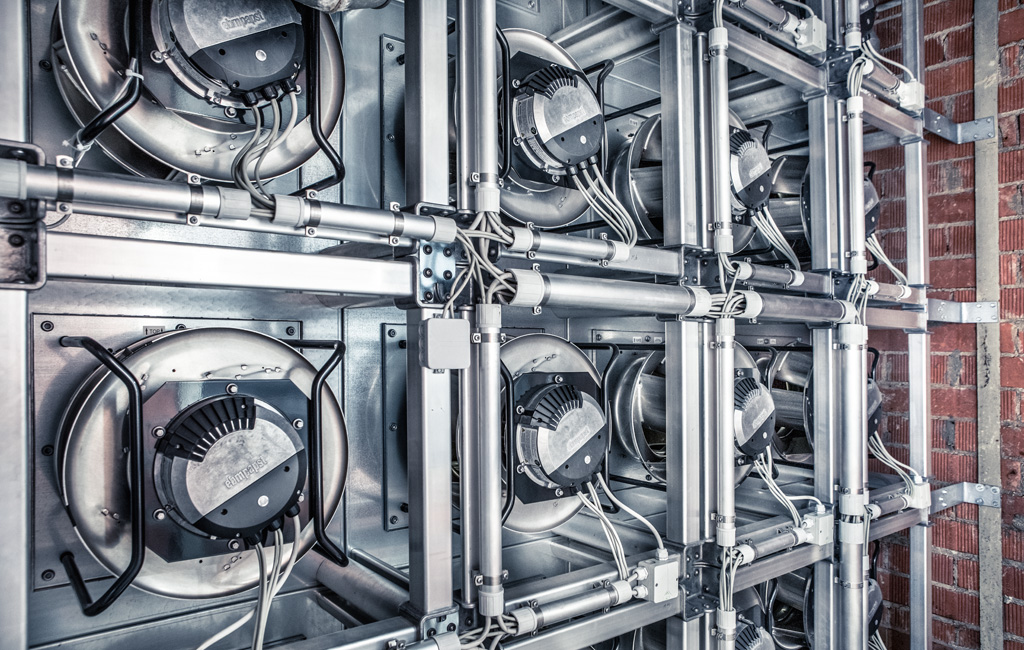

The FanGrid ensures efficient air performance and is so quiet that the shopping experience remains undisturbed. (Foto: Tobias Gerber, Fotogloria)

A race against time

“But it was also clear that we had to act quickly,” Peter recalls. “A shopping center without working ventilation is unthinkable!” So he started looking for solutions and suppliers, checked whether they were able to deliver, and whether they met the criteria on which Sauter FM’s projects are based: the devices had to be modern and energy-efficient, cost-efficient to maintain, and available quickly. The price of the system also had to be right. “We can’t just install something, hope for the best, then find out we’ve made a mistake and expect our customers to put up with it.” During his research, he came across ebm-papst and found that everything there was suitable – the products, the delivery time, the service, the price. Wolfgang Stickel was awarded the contract and contacted the ventilation specialist company from Hohenlohe with an initial idea. “I knew exactly what I wanted,” he says.

“The noise level is very low, even though there’s so much power behind it. The RadiPac fans run very quietly and highly efficiently.”

Peter Halblaub, Facility Manager at Sauter FM GmbH

“I described the problem with our ventilation system to Rudi Weinmann from ebm-papst’s sales department, and told him what I needed from the new devices.” In an on-site appointment with Wolfgang, Rudi was able to get an overview of the situation and discuss the best solution. They quickly found one using the ebm-papst design program FanScout: a FanGrid, i.e. a fan wall consisting of several RadiPac centrifugal fans with EC technology, was to be the solution. “I checked the offer, checked the measurements again, and then we implemented it,” says Wolfgang.

Plasma cutters tackle colossal steel machine

What was a straightforward solution, was in fact anything but straightforward to implement. When the old system was installed 30 years ago, the fan wheel, a steel colossus that weighed several metric tons, was installed via the roof using a crane, and then bricked in. With a diameter of 2.5 meters and a length of 2 meters, it did not fit through the existing door. So to get the huge steel structure out of the room, a bigger piece of equipment was needed. A demolition company got to work with plasma cutters, and transported the parts – once cut down to size – through the door to the outside individually. That was a really weighty challenge.

Peter Halblaub and Wolfgang Stickel are impressed by the power of the sixteen RadiPacs. (Foto: Tobias Gerber, Fotoloria)

Fan on fan

Another challenge was posed by the installation area that was available for the design and construction of the new system, as this was just 5 x 10 meters in area, and did not offer a lot of space. “Pipes and cables made it even trickier to get everything to fit,” says Wolfgang Stickel. But the project team had decided on a modular design for the FanGrid. Instead of a huge fan, Wolfgang and his team installed 16 RadiPacs, each one in size 400, into a large FanGrid. He simply carried the small fans through the door. “A solution with nine fans would have been just about enough, but only just. We wanted to be on the safe side, so we decided on a higher number of fans,” says the certified electrician. “There were some skeptics who doubted that we could actually install 16 fans in the room, but I knew we would manage it.”

Vibrations don’t stand a chance

Bit by bit, Wolfgang and his co-workers installed the RadiPacs and connected them. They paid particular attention to the rigidity and stability of the mechanical connections. “When this many individual fans are assembled into a large fan wall, resonance vibrations can occur. If the wall develops resonance vibrations, then in the worst-case scenario, it can collapse.” In addition, each fan was calibrated individually, and overall resonance measurements were conducted. To keep the vibrations low, the RadiPac centrifugal fans are equipped with resonance detection. Vibration sensors detect the resonances and make them ineffective. During the test start-up, the vibration level is analyzed over the entire speed curve.

If excessive vibration velocities occur, the control software automatically skips the critical speed ranges during operation. At the end, everything was a perfect fit. The fans were sealed on the side facing the existing wall. A tiny door allows access to the rear. “It’s very impressive how all the electrical connections and cables inside are so precisely laid out,” says Peter Halblaub in awe. “We have been waiting for the first big test run for a long time.”

Clean solution: even after ten months, the operators could not find any significant dirt particles in the system during the check. (Foto: Tobias Gerber, Fotogloria)

Test run at full power

The big day finally arrived at the beginning of January. The system was ready to run at full power. Alongside Wolfgang Stickel and Peter Halblaub, the ebm-papst engineers were also present. “It made a real whirring noise when all sixteen devices were running at full speed,” recalls Peter Halblaub. His enthusiasm is evident as he continues: “The noise level is very low, even though there’s so much power behind it. Even when idle, the old machine was noisier. The RadiPacs run very quietly and highly efficiently.” And what about the wall? It was perfect: no resonance vibrations. In the ventilation room, the project team was very satisfied.

Another advantage of the FanGrid is the operational reliability that comes with it. With the 16 fans, the system operates with redundancy. As the system is slightly larger than necessary, even if one fan fails, the nominal operation can be fully maintained by adjusting the remaining 15 fans. This is of great significance to the operator, as in the event of a failure of the ventilation system, there would be a risk of complaints, possibly even going as far as loss of rent.

“With the new solution, we can choose speeds from zero to one hundred, moving along the characteristic curve as required.”

Wolfgang Stickel, Building technician at Sauter FM GmbH

Ten months on from the big day, everyone is still satisfied. “The system is still working perfectly. We have not had a single failure yet,” confirms Peter Halblaub. Controlling the system using FanControl has also proven a success. “The difference is like night and day,” says Wolfgang Stickel. “The old system only had two settings. With the new solution, we can choose speeds from zero to one hundred, moving along the characteristic curve as required. The FanGrid achieves an air flow rate of just over 120,000 m³/h at a static pressure of 1,000 pascals. The system is operated with pressure regulation, which is a highly state-of-the-art function.”

Huge energy savings

The cutting-edge technology of the system is also noticeable when it comes to energy efficiency. “We’re still making adjustments,” explains Peter Halblaub. “But we already know that we consume significantly less electricity. The savings come to almost 50 percent. We also check the system constantly for dirt particles, but so far we haven’t found anything of note.” He is now certain that his decision to install the FanGrid was the right one. So sure, in fact, that he is considering a retrofit for another ventilation system in Neckarsulm. Investing in this kind of fan configuration in the shopping center has paid off.

Leave a comment