Around 8,000 people in Germany and over 54,000 across Europe have cystic fibrosis, a hereditary disease that primarily affects the lungs. Inhalation brings the medication directly to where it is needed and is therefore one of the most important treatment methods for those affected. However, the devices used for this purpose, known as nebulizers or inhalers, can also pose a health risk.

If they themselves become a source of germs, they transport viruses or bacteria directly into the already weakened lungs. Hygienic cleaning of inhalers is therefore an important part of cystic fibrosis therapy – and of everyday life for people with the disease. “Having time for friends, family, and leisure is also a form of inclusion and health. Unfortunately, this is something that many sufferers miss out on,” explains Michael Nordmann, co-founder of Detherma GmbH.

About cystic fibrosis

Cystic fibrosis is a congenital metabolic disease and is considered rare. A change in the cystic fibrosis gene causes an imbalance in the salt-water balance of the cells. As a result, the mucus that covers the cells becomes thick and clogs organs in the body of those affected. The lungs are usually affected, which is why inhalation with inhalettes is often used as a therapy. This is because the inhalers transport the medication directly into the lungs.

Source: Mukoviszidose e.V.

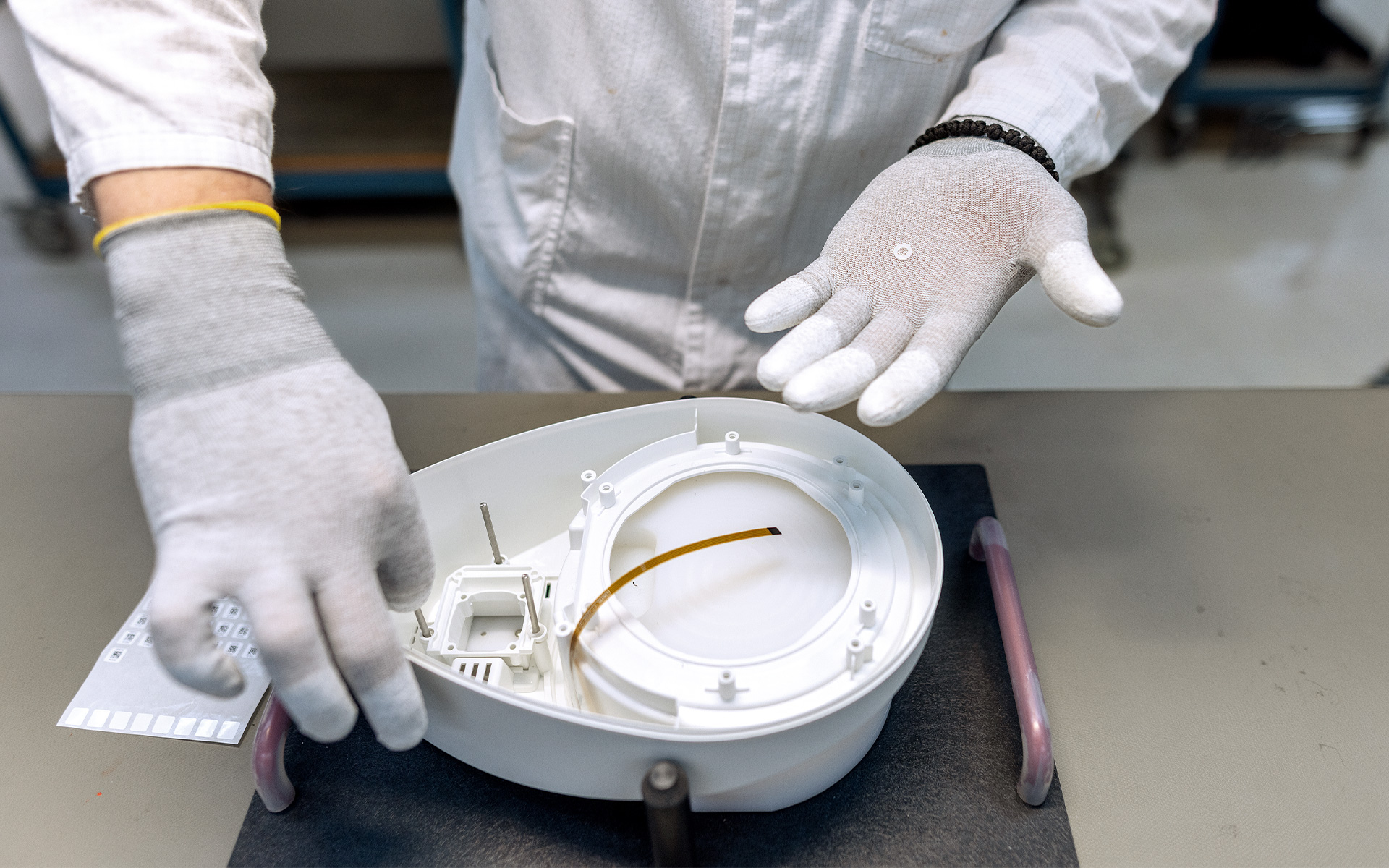

Until 2018, Michael Nordmann himself had no points of contact with cystic fibrosis or inhalers. That is, until he met Peter Krüger through his previous work for an injection molding company. Krüger had developed and patented a disinfection device for stainless steel inhalers. Nordmann was enthusiastic: “He wanted to develop the device into a less expensive plastic one. I found the concept and the idea behind the product convincing.” So convincing that he became an investor and, together with Krüger and three other partners, founded Detherma GmbH as an independent company for the sale of disinfection devices. But what makes the device so innovative?

(Photo | Cornelius Bierer)

Germ-free through drying

There are several disinfection devices on the market that disinfect inhalers without germs. The problem is that they do this with water vapor and the inhalers therefore come out of the disinfection process wet. When they are dried in the ambient air or with a cloth, water droplets remain on the freshly cleaned inhalers. This can lead to the build-up of dangerous, humidity-loving germs. So, for the health of cystic fibrosis sufferers, a device is needed that blows away all the residual water immediately after cleaning.

This is the innovation behind the Detherma device: The nebulizer comes out germ-free and dry, ready for its next use, after just 55 minutes. For the drying process, a compact fan draws in fresh air through a HEPA filter and conveysthe air into the disinfection and drying basket. Compact fans from ebm-papst already performed this job in Peter Krüger’s patented stainless steel appliance. So, when the new plastic product was being developed, it was clear that the same fans would be needed again.

However, despite their experience with the stainless steel device, a few challenges awaited the developers and the compact fan they were looking for: “The fan has to be very powerful so that it can draw in enough air through the HEPA filter. But because the disinfection device is used in the patient’s home, it should still be very quiet, virtually inaudible. And because it is used several times a day, the fan must also work reliably over the long term,” explains Michael Nordmann.

Small damper, big effect

Detherma sent a prototype of the plastic disinfection device to ebm-papst in St. Georgen. Richard Kienzler, Sales Engineer at ebm-papst, suggested using the 422J axial fan due to its small installation dimensions: “It’s very powerful, so it can still deliver the required air flow at a low speed – and therefore quietly. This is due to the blade geometry, which generates the high pressure increase and air flow.” Detherma was satisfied with the initial measurements and installed a larger number of fans in disinfection devices.

However, the noise level was suddenly no longer acceptable in some of them. Some – supposedly identical – devices were loud, while others were not. “ebm-papst then quickly carried out tests in the laboratory that we couldn’t do ourselves,” says Nordmann. Richard Kienzler explains the result of the measurements: “No matter which fans we installed in a loud device, it always remained loud. And the quiet devices remained quiet, whatever the fan model. So it had to be the housing.”

The matter was explained by the discovery that even tiny differences in assembly led to the noise. So Detherma installed a silicone damper in the cover. “Of course as a start-up, it’s a huge bonus for us to be supported by the developers at ebm-papst in this way. Even though we haven’t ordered thousands and thousands of products,” says a delighted Michael Nordmann.

Quality of life for those affected

Detherma is convinced of the importance of the product. What is still missing is official approval as a prescription-only medical product in Germany – a process that may take some time. But Michael Nordmann and his partners are in good spirits: “The feedback from clinics, rehab facilities, and people with the disease has been very positive. Many cystic fibrosis sufferers who use the disinfection device tell us that they have not had any lung infections for a long time. That is, of course, exactly what we want to achieve.”

As a start-up, it’s a huge bonus for us to be supported by the developers at ebm-papst in this way.

Michael Nordmann, Co-founder Detherma GmbH

The disinfection device can also have a positive effect on patients with COPD, a chronic lung disease, as some doctors have already reported. Cleaning inhalers using the Detherma device is very easy for these doctors and their patients. They simply need to put the nebulizer into the device, press the start button, and take it out 55 minutes later, clean and dry. More time for enjoying life – and health.

Leave a comment