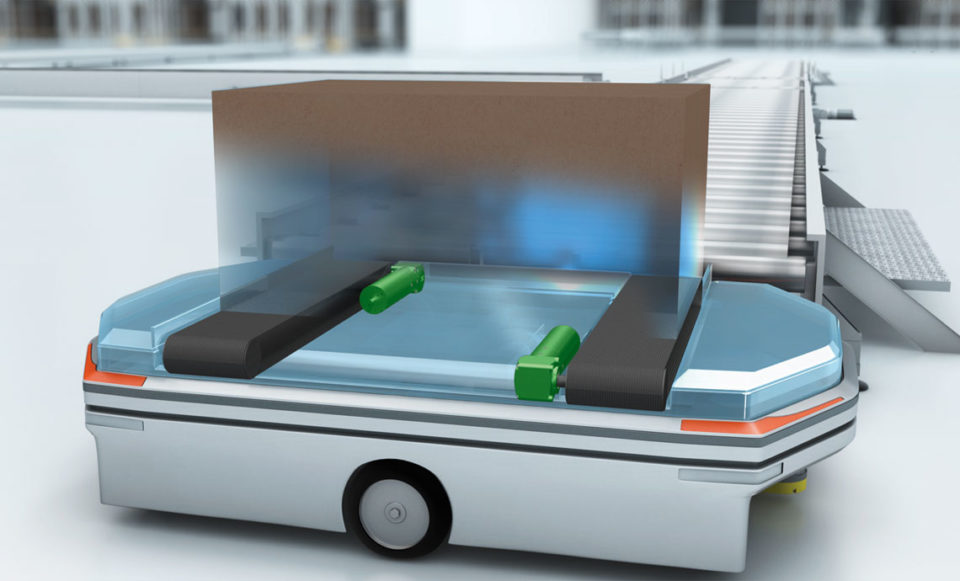

A diverse array of sectors can benefit from automated guided vehicles, from online consumer retailers right the way through to the production lines of the automobile industry. AGVs are deployed both indoors and outdoors. The continuous advancement of the systems and the installed technology has led them to be used flexibly and efficiently in the intralogistics applications of an increasing number of companies. One advantage is their ability to be designed to transport a vast range of goods with different weights and specifications. This is accompanied by other benefits. Automated guided vehicles can be easily integrated into existing logistics structures, to name one example.

Automated guided vehicles can be easily integrated into existing logistics structures.

Subsequent changes or optimizations to the warehouse layout or the warehouse and goods structure are also possible while operation is ongoing. Aside from this, fluctuating power requirements can be easily mastered. The fact that the AGVs are controlled centrally by the management system means they can be scheduled for changing tasks or order peaks at an early stage, and that prioritized journeys can be executed accordingly.

Varying power classes, tasks and requirements

Irrespective of the area of application, the AGVs operate particularly economically when they achieve the longest possible travel routes and times without repeated charging of the on-board energy storage units. This results in fewer interruptions in operation, while the batteries are also conserved and consequently “live” longer. The wheel motors, drive systems for lifting equipment or load-securing devices therefore all need to fulfill special requirements.

Even with a transmission and the safety brakes which may be stipulated depending on the assigned tasks, AGV drive systems should remain lightweight and compact while retaining high power density and energy efficiency. The installation space available for the drive systems is often small, especially in ever-smaller transport vehicles, such as the ones used for distribution systems in warehouses or small load carriers of up to 200 kg. Aside from these constraints, the motors should also be designed for a safety extra-low voltage, not to mention being “smart” to provide relief for the control system.

A range of modular drive variants

Furthermore, the wishes of AGV manufacturers are varied, including where drive power, transmission variants, reduction stages, closed-loop control systems or connection technology are concerned. For this reason, it has become a tried-and-tested practice to put together an ideal, customized drive solution by combining a variety of different modules. The motors supplied by drive system specialist ebm-papst from St. Georgen are a good example of this and are designed for such modular drive systems.

The ECI-42, ECI-63 and ECI-80 model series are perfectly suited to application in AGVs, allowing users to benefit from complete drive solutions from a single source.

A great deal of application expertise is involved in the development of compact, electronically commutated, brushless internal rotor motors. This makes the ECI-42, ECI-63 and ECI-80 model series perfectly suited to application in AGVs, allowing users to benefit from complete drive solutions from a single source. As such, these users only need to deal with a single expert contact in the industry, even with a significant range of variants.

With diameters of 42, 63 and 80 mm espectively, the three motor sizes cover a power range of between 30 and 750 watts and can be flexibly adapted to the specific task at hand thanks to their modular design. In other words, they can be combined with control electronics, transmissions, encoders and brakes.

With diameters of 42, 63 and 80 mm respectively, the three motor sizes cover a power range of between 30 and 750 watts. The drive systems can be quickly and flexibly adapted to the specific task at hand thanks to their modular design. In other words, they can be combined with control electronics, transmissions, encoders and brakes as needed.

Several thousand variants are possible in total.

Several thousand variants are possible in total: Preferred types are ready for shipment within just 48 hours, meaning that the user can quickly make a start with their own development. The motors also impress with their length. The active components (wound stator and rotor equipped with magnets) are just 20, 40 or – in the most powerful variant – 60 mm long, meaning they can be easily accommodated in the tight installation spaces offered by the AGVs.

Free selection of motors, transmissions and brakes

Various transmission modules are available for bringing the high rotational speeds of the internal-rotor drive systems and the output torque to the appropriate level required in the application. Alongside planetary and spur gears, space-saving EtaCrown crown gearheads based on innovative crown-gear technology can also be supplied, for example. The efficient transmissions cover a wide range of reduction ratios, enabling the drive systems to adapt easily to a broad spectrum of tasks.

What is on the inside counts: modular drive systems with integrated logic and power electronics, optional transmissions, encoders and brakes.

If the application in question demands holding or safety brakes, such as for safely maintaining the position of lifting equipment in the event of a power supply failure, modules with permanent-magnet or spring-operated brakes can be added to the drive unit. Redundant encoder systems are one option for safety-relevant applications, while the issue of operational reliability is also taken into consideration when the drive systems are being designed.

A choice of control electronics

There are many application-appropriate options to choose from with regard to the control electronics as well. In the simplest scenario, the motors are equipped with electronics featuring hall sensors for rotor position detection and are actuated by an external, closed-loop controller. On the other hand, if the drive systems are equipped with fully integrated K4 control electronics, they can be configured using simple and intuitively operated PC software. The drive systems can then independently assume numerous processes, which relieves the higher-level control system.

Sinusoidal commutation enables low-vibration, quiet running with pronounced overload capacity and high efficiency.

Three operating modes are possible (for speed, torque and positioning). Sinusoidal commutation enables low-vibration, quiet running with pronounced overload capacity and high efficiency. The K5 control electronics (currently available for the ECI-63.xx) additionally feature a CANopen interface, which opens up further communication options. K5 drive systems can also be used as a CAN master, for example.

The individually configurable drive systems fulfill the requirements of protection class IP54 while also offering variable options in terms of electrical connection. These include industry-standard connectors, in which the radial angled plug with bayonet connector can rotate and engages automatically. An axial plug is available for space-critical applications; even an alternative, preassembled cable connection is possible.

Leave a comment