The EU energy efficiency label first introduced in 1995 was a complete success. Today, electrical appliances such as washing machines, refrigerators, and similar appliances are much more efficient, and therefore better for the environment, than they were 20 years ago. This trend gained additional impetus with the introduction of the Ecodesign Directives in the framework of the EU directive concerning energy-related products (ErP). The scale from A (highest efficiency) to G (lowest efficiency) and the related colored marking, from green to dark red, helped consumers to identify efficient devices at a glance. It provided manufacturers with an incentive to make their products even more efficient.

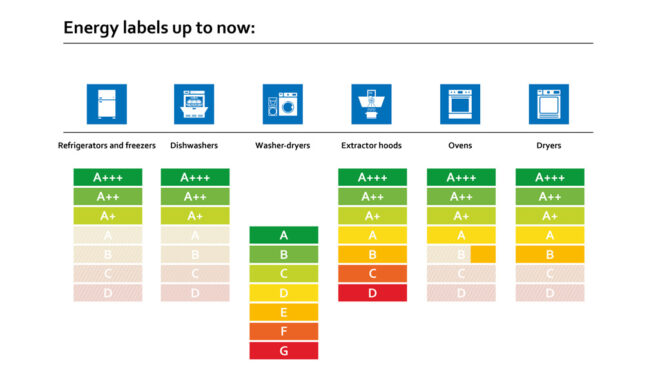

However, the label’s success has long since overtaken its effectiveness. These days, the vast majority of appliances are rated in the highest efficiency classes, and the lower classes E, F and G are rarely assigned at all. The subsequent introduction of additional “plus” classes, which permitted a differentiation within the highest efficiency class (A+ to A+++), has been of little use to customers when deciding which product to buy (Fig. 1). In turn, manufacturers lack the additional incentive to develop more efficient devices if the label will not visually distinguish them from the competition for doing so. However, to reduce CO2 emissions and achieve climate targets, it is urgent that manufacturers increase efficiency levels even further and are more sparing of resources.

Fig. 1: Confusing and unclear: with the old energy label, some efficiency classes were only partially or even no longer in use (see faded out rows), depending on the application. Due to the “plus” classes and different application-based label standards, they were difficult for consumers to follow.

A new scale for greater efficiency

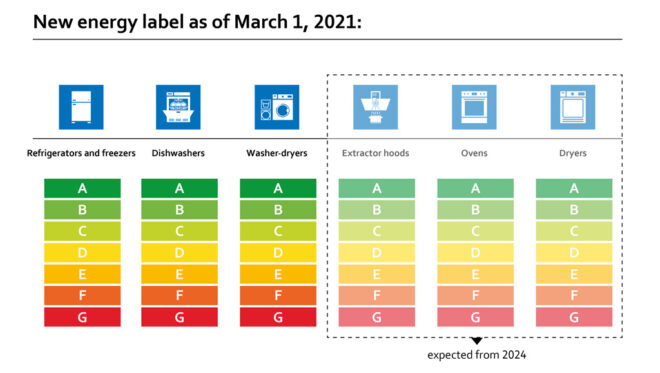

In 2017, the European Union decided to completely reform the energy label, and set out the new rules in the framework regulation EU/2017/1369. A new energy label has now been in force for the first appliance classes since March 1, 2021. The label will be introduced for all other product groups successively (see box text below), as well as retroactively for all products already on the market.

But that’s not all! The new energy label will also be introduced for extractor hoods, dryers, boilers and hot water heaters, as well as a range of other product groups, in the foreseeable future. Some of the respective Ecodesign Directives are already in the review process, or will be soon. In the case of boilers and water heaters, for example, this is already underway.

In the case of extractor hoods, we have seen how the previous energy label has been expanded by three “plus” classes in recent years, with the corresponding classes E, F, and G being removed in conjunction with this. The review of the relevant Ecodesign Directive has taken place and with it the changeover to the new energy label.

Which device and appliances does the energy label apply to?

In principle, the previous energy labels apply to a total of 15 product groups. These include washing machines and dryers, air conditioners, fans, televisions, and TV boxes.

The new energy label has been valid for the following types of appliances as of

March 1, 2021:

- Dishwashers

- Washing machines

- Washer-dryers (washing machine and dryer in one unit)

- Refrigerators and freezers

- TVs and monitors

Set to follow from September 1, 2021, with an 18-month transition period:

- Light sources

From 2024 (anticipated):

- Dryers

- Ovens and extractor hoods

- Vacuum cleaners

- Air conditioners

From 2026 (anticipated):

- Room heaters

- Water heaters

- Solid fuel boilers

From August 2, 2030, all product groups are to have a new label.

The differences to the previous label are evident (Fig. 2). Anyone who has looked for a dishwasher or washing machine may have rubbed their eyes in disbelief and wondered why all the efficient devices seem to have disappeared. Nothing currently on the market occupies Class A according to the new rating system. This is completely intentional. The intention of the rescaling is not simply to relegate the existing efficiency classes, but to create new incentives for innovations and for the new scale to be applicable for the next ten years.

In addition to getting rid of the “plus” classes and returning to the scale from A to G, however, the most important reform is adapting the evaluation criteria and making them more stringent. What used to satisfy the criteria for A+++ would now be ranked as Class B in a best-case scenario, and in some cases, as low as Class D.

Fig. 2: Consistent and clearly structured, regardless of which consumer device it concerns: the new energy label makes it much easier for consumers to compare products.

This means that it is no longer possible to directly compare old and new labels. Although the energy efficiency index (EEI) remains crucial to the classification, the underlying measurement and calculation methods have changed. The new ones are much more extensive and complex. For example, new evaluation methods have been introduced for measuring energy consumption.

A flaw in the old label was that the eco mode was the decisive factor in the classification, for example, in the case of washing machines and dishwashers. In practice, this does not reflect real user behavior. Eco mode usually took much longer, which meant that many consumers used the faster programs more frequently, which consume more energy and water. In future, the evaluation process should also take these factors into account (see overview of box text below).

What is changing as a result of the new label?

The new energy label is intended to better inform consumers about the efficiency of a product. Class A is initially being left empty, in order to promote innovation and to preserve its validity for as long as possible. The most important changes at a glance are as follows:

- The “plus” classes A+, A++, and A+++ have been scrapped

- The new scale ranges from A (highest efficiency) to G (lowest efficiency)

- New assessment and measurement methods apply to the classification

- A QR code links to the “European Product Registration Database for Energy Labelling” (EPREL). All manufacturers whose devices bear an energy label must register them with EPREL and record the technical data there before they are permitted to sell the products in the EU.

- For the first time, there are also special requirements for resource efficiency (repair and recycling capability).

The more stringent requirements are derived from the EU’s Ecodesign Directives, which were issued and revised at the same time. Among other things, they define minimum energy efficiency requirements. As of a defined target date, it will no longer be permissible to sell devices that do not meet these.

As part of this revision, resource efficiency has been added as a completely new requirement. The aim is to make devices easier to repair, so that they can be operated for longer. Therefore, manufacturers are responsible for designing their products so that parts can be easily removed and installed. And once a consumer product is no longer on the market, certain spare parts must remain available in the short-term for a prescribed period of time. To begin with, this regulation will apply to washing machines, washer-dryers, dishwashers, refrigerators and televisions.

Database for greater transparency

In order to increase transparency for consumers and facilitate market monitoring, a new electronic database has been created alongside the new energy labelling regulation, known as the “European Product Registration Database for Energy Labelling”, or EPREL for short. It is divided into a public and a non-public area. The latter is only accessible to the market supervisory authorities and the European Commission, and contains the extensive technical documentation of the products.

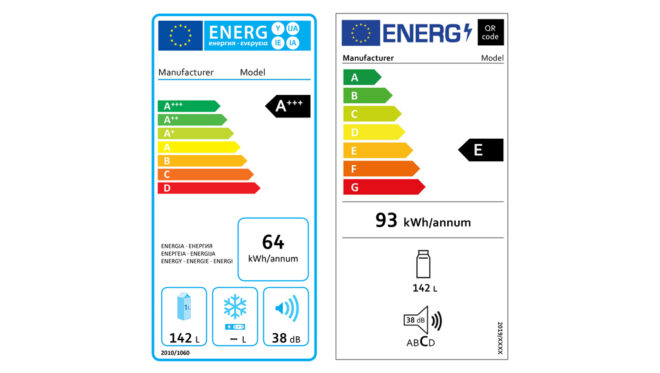

Appliance information such as manufacturer data, model identification, and energy efficiency class is accessible to the public. Consumers can find this either on the Internet or using the QR code on the energy label. This makes it much easier for consumers to compare appliances from different manufacturers (Fig. 3).

Fig. 3: Old and new labels are not comparable. As this example of a fridge shows, there can be major differences. The reason for this is the new testing and evaluation criteria. Another new feature is the QR code, which leads directly to the new EPREL database, in which all labeled products are recorded.

The EC technology pioneer

Alongside the reclassification of their existing products, manufacturers are under considerable pressure to innovate, so that the appliances affected can be rated in higher efficiency classes in the future. Unlike when the energy label was first introduced in the 1990s, many options for increasing efficiency appear to have already been exhausted. Development departments find themselves asking what improvements are left to make to further optimize their products.

Fan and motor manufacturer ebm-papst is a pioneer in EC technology. Since the first energy label was introduced, it has helped manufacturers to ensure that their products can compete in terms of efficiency, by providing environmentally friendly motors and fans. In the last 20 years, EC technology has replaced AC technology wherever possible. This is hardly surprising, as the electrical efficiency of EC motors far exceeds that of AC motors.

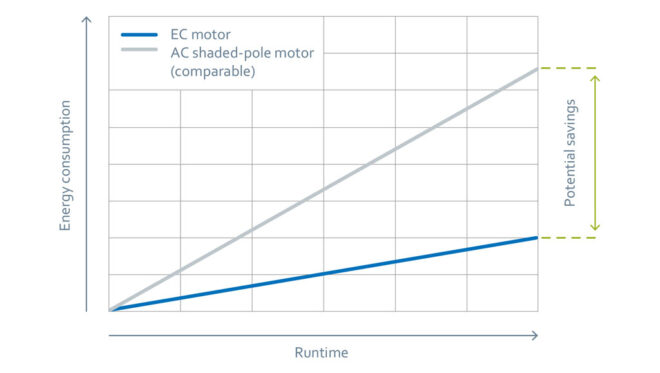

Motors are among the largest current consumers in refrigerators, washing machines and dishwashers. Replacing less efficient motors with more efficient ones is a quick way to achieve good results (Fig. 4). Wherever EC technology is not yet in use, they continue to represent an important step towards producing efficient products.

Fig. 4: Comparison of AC motor and EC motor: The longer the running time, the greater the efficiency and therefore the cost advantage of EC technology in comparison with AC technology.

The whole system counts

However, the more stringent regulations mean that it is no longer possible to achieve greater efficiency simply by using more energy-efficient individual components such as motors and fans. To achieve greater increases in efficiency, it is essential to consider and optimize the entire system. To achieve this, it is necessary to finely coordinate the components in the early stages of development, or the effect of the efficient EC technology can quickly disappear.

In addition, there are many dependencies within a single appliance, meaning that considering each individual component alone is not enough. For example, in the case of extractor hoods, there are various requirements that need to be optimally coordinated, such as the suction power and the air filtering performance (of grease and odors). The acoustics must not be ignored either, and the appliance should be simple and convenient to use. Last but not least, the upcoming review of the old ecodesign specifications for extractor hoods will focus specifically on energy efficiency.

As an expert in electronics, motor design and aerodynamics, ebm-papst works closely with manufacturers from an early stage to help them select components for the development of a new product.

When it comes to dishwashers, a blower can perform a lot of tasks, e.g. heating, drying, or providing process air. The same applies to the acoustics. The installation and operating conditions play a decisive role in ensuring that the appliance remains quiet during operation. In most cases, it is necessary to reconcile various different efficiency targets. With a dishwasher or washing machine, manufacturers must focus on saving both energy and water, without impacting perfect rinsing or washing results.

This makes finding the optimum operating range much more challenging. As an expert in electronics, motor design and aerodynamics, ebm-papst works closely with manufacturers from an early stage to help them select components for the development of a new product. The developers rely on state-of-the-art laboratories with test stands specifically equipped to deal with these issues, as well as special simulation tools.

More intelligence for components

In the future, the intelligent interplay between many different factors may become the most important element in achieving further energy savings. As it is becoming more and more crucial to optimize the overall system, the individual components must be designed for optimum compatibility and, increasingly, communicate with one another.

For example, if the control system knows the exact operating point of a fan, it can calibrate it using data from the other components and, depending on the operating conditions, automatically adjust various factors, such as the speed. As a result, the use of sensors is becoming increasingly important, and with it, the necessary communications interfaces.

With “GreenIntelligence”, ebm-papst offers and develops ecologically sustainable solutions for fans and motors that enable intelligent control and networking with other components.

Forward looking and sustainable

This also applies to resource efficiency. Using computer-aided simulation tools, it is possible to optimize the use of materials as early as the design phase. Furthermore, motors and fans are generally designed for durability and robustness and have frequently proven to have a long service life on the test stand.

Supplementing this with precise knowledge of real operating states helps to achieve maximum resource efficiency and availability throughout the appliance’s service life. The housing and interfaces can also be designed to make components easy to replace, should this need ever arise.

Furthermore, motors and fans are generally designed for durability and robustness and have frequently proven to have a long service life on the test stand.

It now remains to be seen whether the new energy label will be as successful as its predecessor. Estimates by the European Union assume that by 2030, the set of measures from the new Ecodesign Directives will achieve annual EU-wide energy savings of 167 terawatt hours (TWh). This roughly corresponds to the annual energy consumption of Denmark. Broken down, this means that on average, European households could save 150 euros per year.

The topic of “efficiency” is not only relevant for the European market. Non-European countries and regions, such as the USA, are also continuously tightening the criteria for their respective energy labels.

Leave a comment