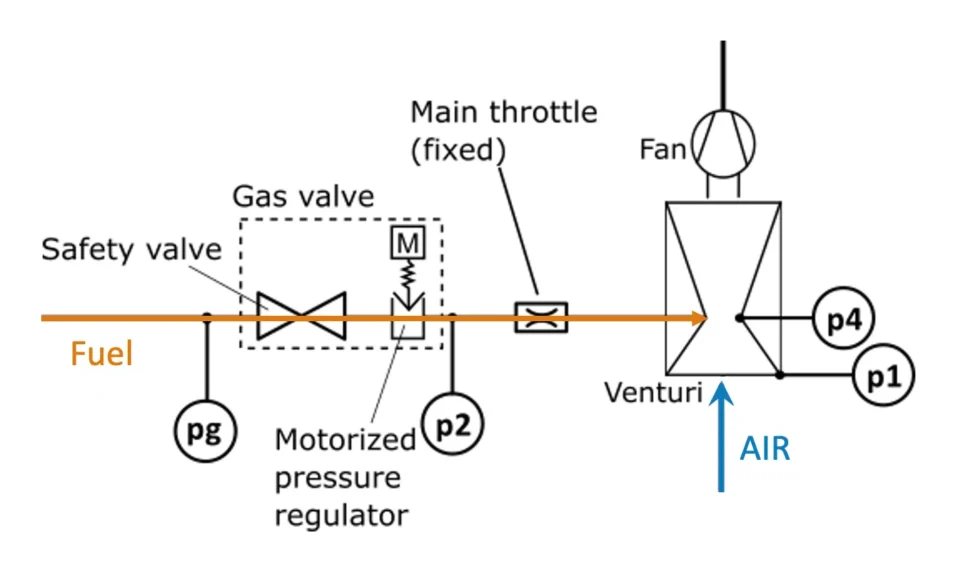

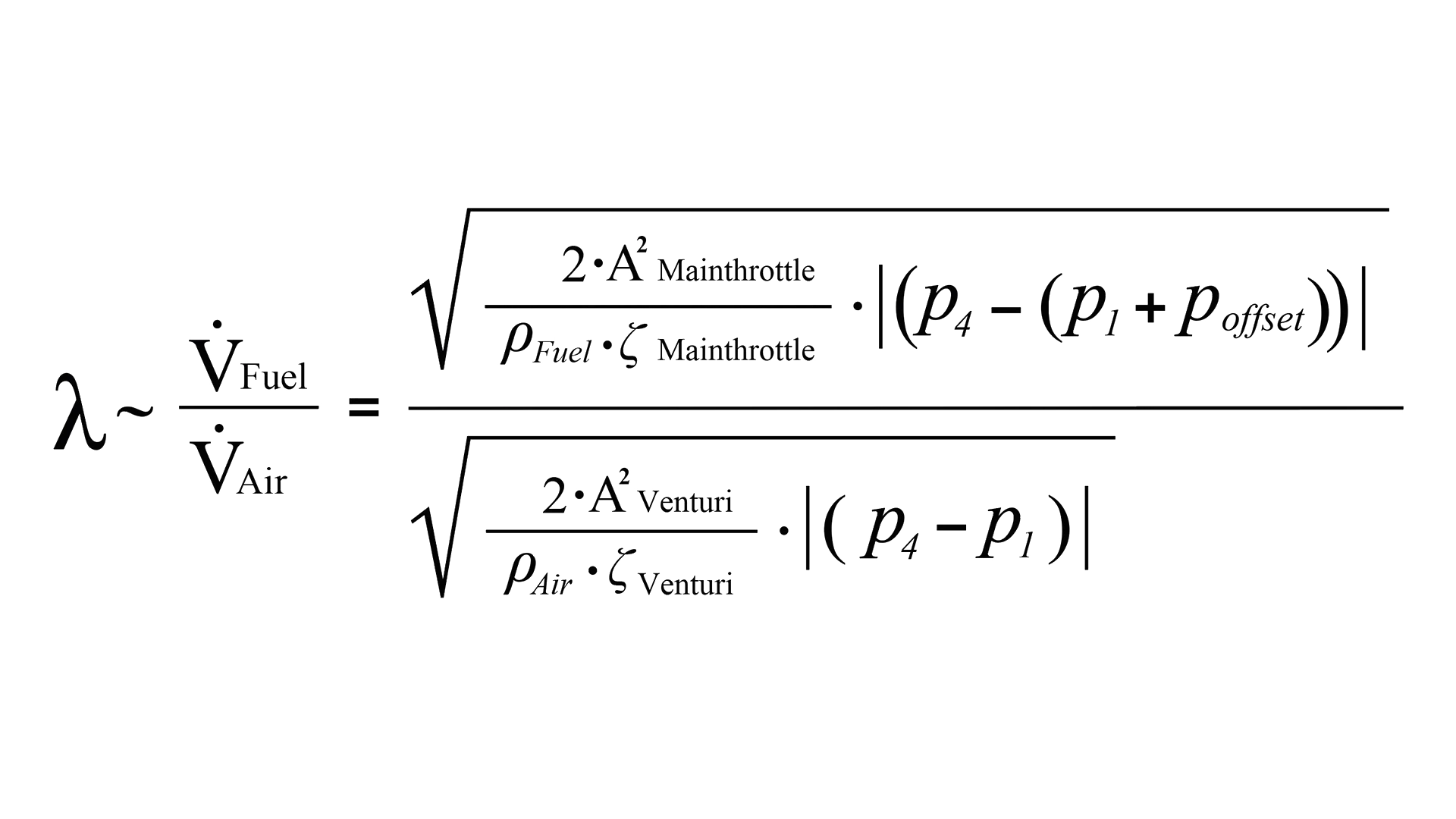

The mechanical-pneumatic ratio control system has established itself as a reliable principle for controlling the mixture in gas condensing boilers: A blower draws in ambient air via a venturi, and a vacuum is created that opens the gas valve and draws in the fuel. The air/fuel ratio (λ) is considered ideal at λ = 1.3 and is calculated as the quotient from the volumetric flow (VFuel ) of the fuel and air (VAir ).

ebm-papst in heating technology

Whether efficient components or complete, perfectly coordinated systems – enjoy the benefits of our established and constantly updated technology.

The volumetric flow indicates the quantity of fluid, i.e., gas or air, flowing through a defined surface area over a certain period of time. For air, the surface area in a condensing boiler is determined by the venturi. In the case of gas, it is determined by the main throttle. Both components act as a resistor in the sense of fluid mechanics, which results in a pressure difference (ΔP) between the inlet and outlet.

Together with the surface area (A), the coefficient of resistance (ζ) and the density (ρ) of the medium, this significantly influences how high the volumetric flow is. This relationship was described back in the 18th century by Daniel Bernoulli, whose equation forms the theoretical basis for calculating the volumetric flow. It can be found in the numerator and the denominator of the formula shown here.

As the geometry and, therefore, the surface area of the main throttle and venturi are fixed, the only variable parameter left is the pressure difference. For air, this stems from the atmospheric pressure (p1 ) and the venturi pressure (p4 ), which is dependent on the blower. For gas, it is the difference stemming from venturi pressure (p4 ) and the pressure at the outlet of the gas valve (p2 ), which comprises the atmospheric pressure (p1 ) and what is known as the offset pressure. In a mechanical-pneumatic ratio control system, the offset pressure is set once as a fixed setting when the system is commissioned.

This is not a problem as long as the mixing ratio does not need to be changed during operation. An electronic gas valve makes the system more flexible: It enables the offset pressure to be controlled via software and, therefore, the gas volumetric flow to be actively controlled. This plays an important role when using pure hydrogen as the fuel, for example. As it is highly reactive, the gas content can be reduced for a brief moment during the ignition in order to prevent issues like flashback. In addition, the more precise control over the air ratio enables a higher modulation level, and the operation of the condensing boiler can be adapted more accurately in line with the actual heat demand.

Leave a comment