What is the advantage of the new pre-mix blower?

Up until now there has not been a suitable high-efficiency, modulating gas blower on the market for single boilers with a heat output of more than one megawatt. Multiple boilers had to be operated in cascade arrangement to achieve higher outputs. The G3G 315 pre-mix blower is designed for a heat output of up to two megawatts. That is the level of heat output required to provide 50-story apartment blocks or roughly 100 individual houses with heating and hot water, for example. And that can now be achieved with one boiler. Which means that not only is less space required, it also cuts maintenance costs.

Up until now there has not been a suitable high-efficiency, modulating gas blower on the market for single boilers with a heat output of more than one megawatt. Multiple boilers had to be operated in cascade arrangement to achieve higher outputs. The G3G 315 pre-mix blower is designed for a heat output of up to two megawatts. That is the level of heat output required to provide 50-story apartment blocks or roughly 100 individual houses with heating and hot water, for example. And that can now be achieved with one boiler. Which means that not only is less space required, it also cuts maintenance costs.

Where are such gas-condensing boilers used?

There is a distinct trend toward ecological gas heating systems situated on the spot for local supply. In the light of rising energy prices and stringent environmental standards for new buildings, a district heating supply is not always an ideal solution. Even if the pipes are well insulated, the heat losses during transportation of the heating water and the material expenditure for laying pipes over long distances are simply too high. Decentralized heating solutions with natural gas pipes make it possible to reduce this outlay. On top of that, natural gas pipes are virtually maintenance-free. A local heating supply is thus far more efficient for large buildings like apartment blocks, as well as for residential areas.

How did ebm-papst enhance the performance of the blower?

Christian Diegritz, Head of Product Management, Marketing and Communication at ebm-papst. (Photo | ebm-papst)

Development was based on an existing motor platform that we then adapted to the special requirements of the heating sector. For instance, we managed to obtain an optimum balance between the aerodynamics of the impeller and the motor characteristics. Speeds of up to 6,000 revolutions per minute are now possible thanks to the new motor and electronics configuration. Together with the optimized air routing of the fan, this permits a broad blower modulation range of up to 1 : 8. And so the gas-condensing boiler can operate economically even with a widely fluctuating heating demand.

What is the situation with regard to technical incorporation into applications?

Alongside efficient combustion, ease of incorporation into modern control systems was a further important aspect for us. All the important data are transferred via a standardized interface in the motor actuation system. These data can also be exchanged by way of a MODBUS interface.

Efficiency close to home

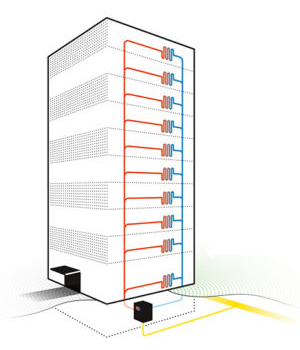

A local heating network is substantially more efficient than district heating. But to date there has been a lack of space-saving solutions for gas-condensing boilers. The new pre-mix blower from ebm-papst will change all that.

A local heating network is substantially more efficient than district heating. But to date there has been a lack of space-saving solutions for gas-condensing boilers. The new pre-mix blower from ebm-papst will change all that.

50 stories or 100 individual houses

A high-efficiency boiler with an output of two megawatts can supply up to 50 stories or a residential area with 100 individual houses.

A single boiler

In the past, multiple condensing boilers had to be combined to produce such an output. Now a single boiler is sufficient. That cuts the costs of installation, operation and maintenance.

Less complicated, more quickly implemented

With a natural gas supply, energy can be conveyed without any losses even over long distances. What’s more, a single gas pipe can transport more energy than a complex district heating piping system with insulated supply and return pipes. The infrastructure is thus less complicated, and building projects can be implemented more quickly even in conurbations.

That the very useful information i get after reading the article about energy efficiency by putting a modulating gas blower for boiler.