Supermarkets have not sold by the season for a long time. Fresh and crispy tomatoes, peppers, and other produce are available in the produce section throughout the year, regardless of the season. By providing summery conditions during the winter, greenhouses are one of the things making this possible (Fig. 1). The situation has benefits for both consumers and farmers. The latter can use greenhouses to harvest more crops and minimize risk in the process: under a protective roof, weather-related crop failures and hail damage are not an issue. In principle, with smart irrigation systems and air conditioners, plants can even thrive in places where nature would not normally allow it, such as deserts or cold regions.

A question of distribution

Unfortunately, cold or hot spots may arise over the entire greenhouse area. Only limited plant growth is possible in such places, and the plants are more susceptible to disease there. Photosynthesis and plant growth are strongly dependent on the temperature. If it is too cold, photosynthesis proceeds very slowly; if it is too warm, it comes to a stop very quickly.

AxiCool fans from ebm-papst enable precise control of the air flow.

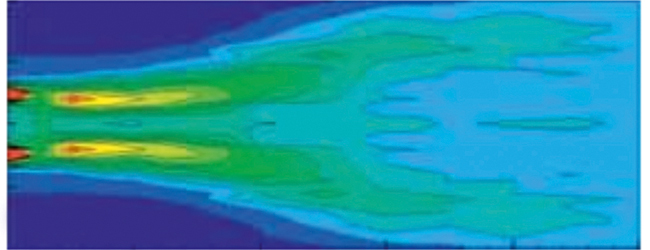

On the one hand, the optimum temperature that needs to be evenly distributed throughout the greenhouse depends on the type of plant. And on the other hand, a good supply of fresh air and air circulation are the keys to a good harvest – alongside the right temperature and humidity. This is why the goal is to create uniform climatic conditions with a roaming air flow by evenly distributing the air at a constant speed over the entire greenhouse.

Horizontal ventilation is a common method of evenly distributing the air in greenhouses (Fig. 2). In this method, the air is guided above the plants in the horizontal direction. As a rule, fresh air is supplied through the sides of the greenhouse. A highly innovative air supply method is the use of ventilation tubes from below (Fig. 3). This process ensures that sufficient CO2 reaches the plants. This is particularly important since CO2 is the base substance for photosynthesis in plants.

Solution from refrigeration technology

Greenhouse operators have the option to use a ventilation system that meets all of the plants’ needs and is also easy to install. The solution uses AxiCool axial fans from ebm-papst (Fig. 4).

Figure 4: AxiCool fans with guide vanes on the outlet side are used for horizontal ventilation. They have a white housing to reflect as much of the incident light (important for plant growth) as possible. (Photo | ebm-papst)

They were originally developed for refrigeration technology since even temperature distribution is also important to keep goods fresh in cold storage rooms. That also makes them ideal for greenhouses. They feature high air throw and enable precise control of the air flow.

Guide vanes are also installed on the outlet side of AxiCool fans to improve overall efficiency (Fig. 5). The housing and mounting are white in order to reflect as much incident sunlight from the greenhouse as possible. To meet the service life requirements, the fans are specially equipped for use in the high humidity of greenhouses, and their plastic components are made of UV-resistant materials that are also easy to clean. With their aerodynamic blade design, axial fans also run very quietly – a major improvement in working conditions for the employees.

ebm-papst Inc. in Farmington, U.S.A. developed a height-adjustable mounting system for the AxiCool fans that is easy to install. It allows the fan position to be adjusted to the plant height, which changes as the plants grow. This adds up to a customized, high-power air guiding system that optimally simulates the natural movement of air.

Innovative: Air supply from below

Energy-efficient backward-curved centrifugal fans or especially high-pressure axial fans from ebm-papst are used for the tube ventilation system (Fig. 6). The air is supplied through a perforated tube installed under the plants. The axial fans intake air that has usually been conditioned (temperature-controlled and humidified/dehumidified) from the air treatment chamber of “semi-closed” greenhouses.

The air is first pressed into the tube, flows upward through holes past the plants, and is then guided back into the intake air flow. The result is a defined circuit of air flow. With this type of air supply, the undersides of the leaves are optimally supplied with CO2. This is especially efficient, since that is where the intake for photosynthesis occurs. Thanks to the high-powered fans, especially long tubes can be used. Such systems enable the implementation of efficient ventilation solutions for maximum yield in large-scale greenhouse installations such as those in the United States and also in European countries such as Spain and the Netherlands.

Figure 6: High-pressure axial fans for tube ventilation that supplies the plants with CO2 from below. (Photo | ebm-papst)

Energy saving made easy

It is also important to have energy-saving EC motors drive the fans. These grid-fed, permanently energized, synchronous motors with electronic commutation, also called BLDC (brushless DC) motors, boast efficiencies that are far above efficiency class IE4. An innovative greenhouse design in Canada uses ebm-papst AxiCool fans and its electricity bills were reduced by more than 70% in comparison to the ventilation technology previously used.

EC motors have another advantage: their control characteristics. They can be controlled across the entire speed range while retaining their high efficiency in partial-load operation. This means that fans on smooth walls can be set to a higher speed than fans on walls with protrusions or obstacles. Air flow effectiveness can be optimized with this precise tuning. Digital MODBUS-RTU, which use the 4–20 mA or 0–10 V interface, can be used to control the fans as needed. The MODBUS communication interface can be used to configure and monitor the fans according to the situation in the greenhouse with utmost precision.

Ideal air solution

- Air supply and mixing are important factors for plant growth and can be precisely controlled with axial fans from ebm-papst. Their most important advantages:

- UV-resistant white housing for maximum light reflection

- Space-saving configuration for limited shading

- Energy-efficient, maintenance-free GreenTech EC motors

- Especially quiet operation

- Fan system with on-board electronics for easy plug & play startup

- Speed control as needed via MODBUS-RTU, 4–20 mA or 0–10 V

Leave a comment