Oliver Haaf, Group Leader in Prototype and Function Development for Aerodynamics at ebm-papst in Mulfingen

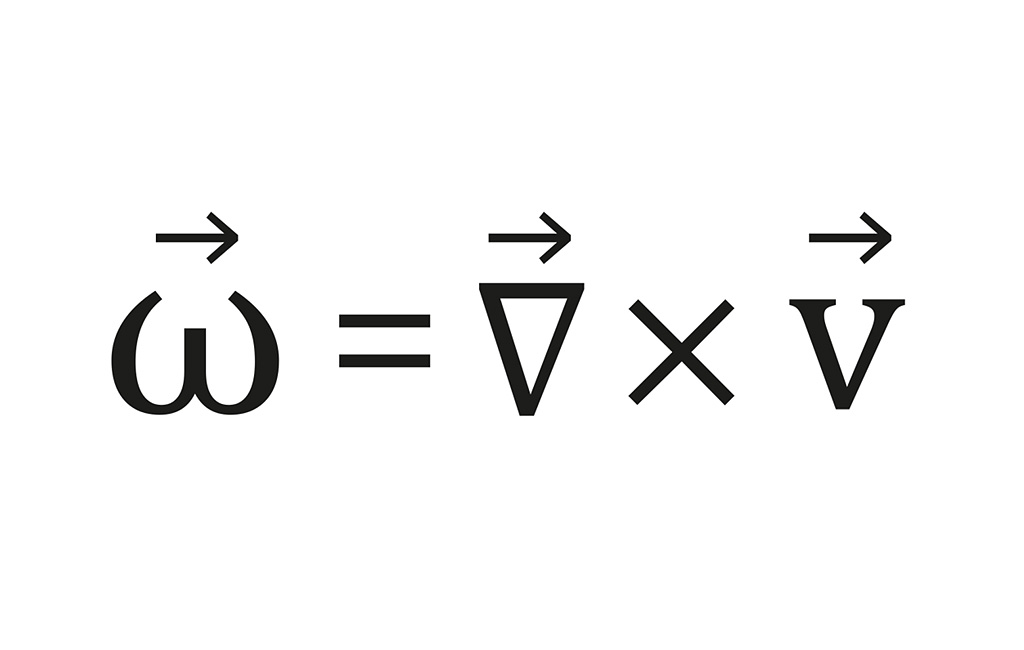

A velocity field’s rotation is given by the cross product of the directional derivative vector (∇) and the velocity vector (v). It specifies how fast or how strongly a vortex in a flow field is rotating around its center. The vorticity can be influenced by making changes in the blade geometry near the gap between the fan and its housing. Noise increases with increasing vorticity.

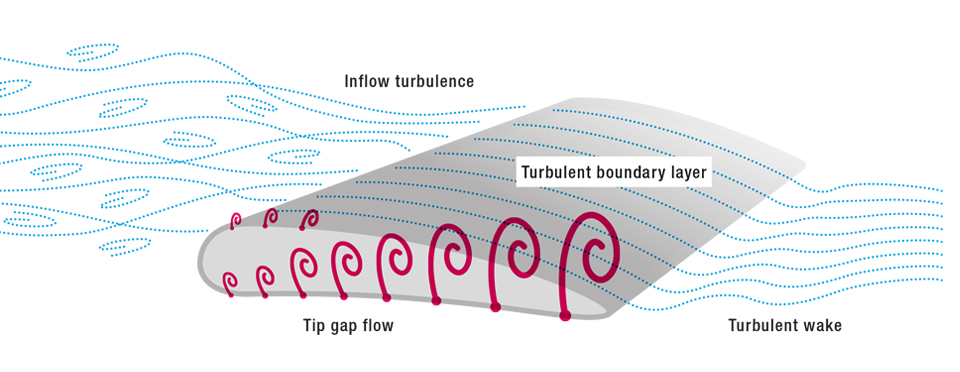

For axial fans, the pressure difference between the intake and outlet sides results in a flow over the fan blades in the vicinity of the housing wall. The flow interacts there with the edges, the blade surface and the surrounding housing wall. Vortices form which can raise the noise level by up to 10 dB.

The gap between the blade tip and the fan housing has a major impact on the noise level, with the noise decreasing as the size of the gap is reduced.

Winglets can influence the vortices with different geometries. One possibility is to reduce the velocity vector v of the vortices. So-called T-winglets increase the flow resistance in the gap area, thus reducing the vorticity (ω = ∇ × v) and consequently the noise generated when the vortices strike solid surfaces.

The other possibility is to reduce the vorticityωby changing the blade contours: The blade is rounded off in the gap area and the edges over which the gap flow streams are removed — similar to the winglets on airplane wings. These blades only have an edge on the outlet side of the gap flow, so vortex formation is significantly reduced — this influences the gradient vector (del operator ∇ = ∂/∂x, ∂/∂y, ∂/∂z) = directional derivative vector).

The flow interacts in the vicinity of the tip gap with the neighboring edges, the blade surface and the surrounding housing wall. The strength of the resulting tip gap vortex depends on the design.

The winglet geometry that is best suited to a particular axial fan is determined by the required separation between the rotating (blade) and stationary (fan housing) components.

The interaction of the two components is crucial and the geometries have to fit in order to achieve optimal results. A good example is provided by the AxiBlade axial fans made of strong, glass-fiber reinforced plastic that enables the winglet shape to be adapted to the interaction with the newly developed housing geometry, reducing the noise generated at the gap.

Leave a comment