By adopting the Kyoto Protocol, the European Union has undertaken to reduce CO2 emissions by at least 20% by 2020. One measure for achieving this is the EuP directive (Energy-using Products directive) adopted by the EU in 2005, which was renamed the ErP directive (Energy-Related Products directive) in 2009 and is also referred to (in Germany) as the eco-design directive. Within its framework, the savings potential of energy-relevant products are examined and minimum requirements are defined. For example, in the field of lighting, this has already had concrete impact: 100W bulbs are due to disappear from the market. Now, mandatory limits applicable for fans were defined in June 2010.

When the ErP directive becomes effective for fans, fan manufacturers will be required to design their products for the European market to comply with defined efficiency standards to make an important contribution to reducing energy consumption. This will affect all fans in the power range from 125 W to 500 kW, regardless of whether or not they are operated as single units or as integrated components within a system. This concerns all conceivable applications, from refrigeration and air-conditioning technology through to mechanical engineering and IT applications.

Two-stage plan with strict standards

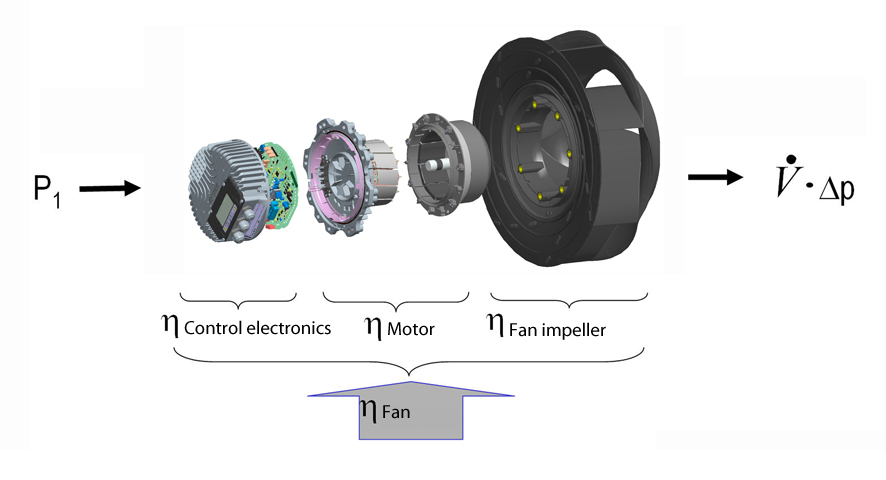

To decide whether a fan satisfies the ErP Directive, the efficiency of the complete fan is assessed, i.e. the unit of control electronics (if fitted), motor and fan impeller

The EU has specified a two-stage plan with strict standards to keep “energy-burners” off of the European market in the future. The first stage will become effective on 1 January 2013. Some 30% of all fans currently on the market will then no longer satisfy European regulations. In the second stage, from 2015, another 20% will be replaced by more efficient products. These will satisfy the specified minimum efficiency levels.

The user can recognise fans that satisfy the requirements of the directive by the CE sign, which will then give energy efficiency the same significance as compliance with the low-voltage and EMC directives. Labelling in the way practiced with washing machines, refrigerators etc. is not planned for fans as the fan manufacturers usually have no influence over the installation conditions.

Challenging limits

To decide whether a fan is compliant with the ErP directive, the efficiency of the complete, ready-to-use fan is assessed, i.e. the unit comprising control electronics (if fitted), motor and fan impeller. The corresponding limits have been set very high. The efficiency cloud illustrates the limits that are set to become valid in 2013 and 2015, shown in the form of black lines. At the same time, the efficiency of conventional centrifugal fans from ebm-papst’s broad product range are entered in the diagram. The “efficiency cloud” shows that not all fans satisfy the future requirements. But it can also be seen that for every fan that will no longer be permitted in the future, there is already an energy-efficient replacement that not only fulfils the specifications of the directive, but actually exceeds them.

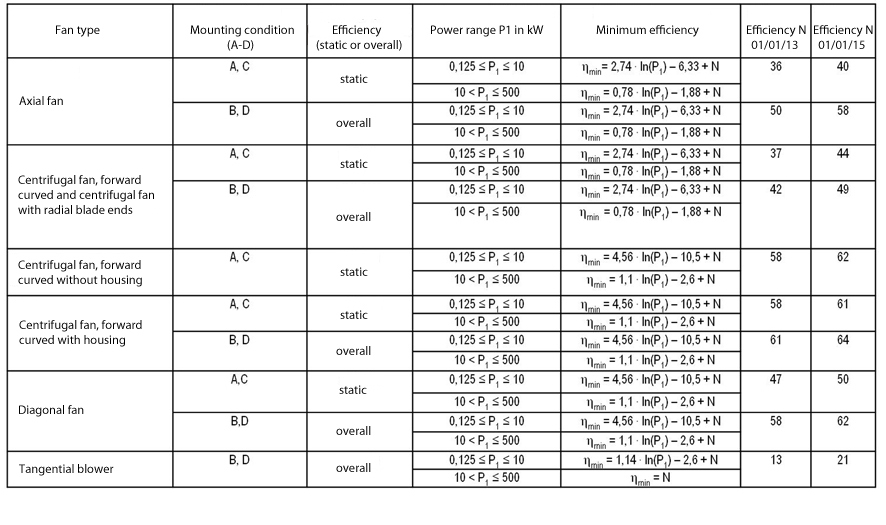

For axial fans, forward and backward curved centrifugal fans, tangential blowers and diagonal fans, the EU has specified the corresponding formulas with which the respective minimum efficiency can be calculated. In the assessment, different power ranges and mounting conditions are taken into account for the measurements. The target efficiency, that is the concrete specification for an axial fan in the power range from 0.125 to 10 kW, can be calculated using the following formula:

To determine the efficiency, the EU specifies the relevant formulas that are used to calculate the minimum efficiency for each type of fan

Minimum efficiency ηmin = 2.74 x ln (power input P1 in kW) – 6.33 + N. Where N is a constant defined in the directive. For axial fans, this will have the value 36 from 1 January 2013 and 40 from 1 January 2015. This factor can be looked upon as a kind of political “setting screw” for a further tightening of requirements in the future. For the HyBlade® axial fan illustrated in Figure 4 with a drive output of 0.69 kW at optimal operating point, the formula states that an efficiency of at least 28.65% must be achieved from 2013 and at least 32.65% from 2015, based on the static pressure increase. The curve indicates 40% efficiency, which is already substantially higher than the minimum requirement for 2015. This fan thus already satisfies the future specifications.

The future belongs to EC technology

HyBlade® axial fan in EC technology, which not only fulfils the strict energy efficiency requirements, but actually substantially exceeds them

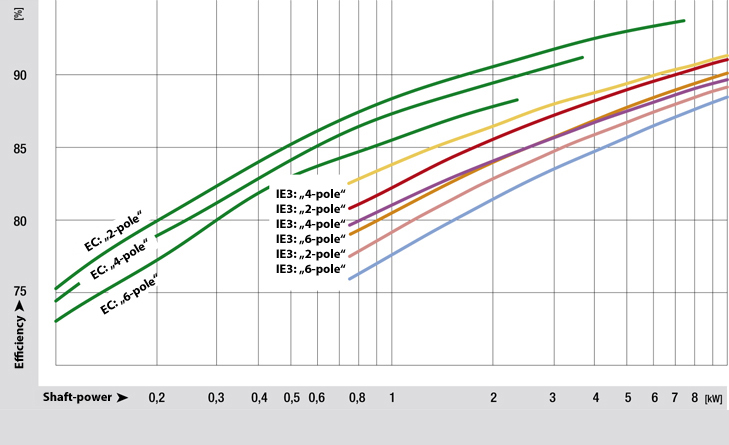

The efficiency cloud shows examples of just how demanding the limits specified by the ERP directive are. Against this background, the EC technology developed some years ago by ebm-papst is the first choice for electrically powered fans. Compared to conventional fans with asynchronous motors (AC technology), EC motors achieve an efficiency of more than 90%. That means energy consumption up to 50% lower compared to AC solutions. Moreover, the speed of EC fans can be controlled so that the air volume can be adapted to suit the specific requirements, which also results in further substantial energy savings.

The efficiency cloud shows examples of just how demanding the limits specified by the ERP directive are. Against this background, the EC technology developed some years ago by ebm-papst is the first choice for electrically powered fans. Compared to conventional fans with asynchronous motors (AC technology), EC motors achieve an efficiency of more than 90%. That means energy consumption up to 50% lower compared to AC solutions. Moreover, the speed of EC fans can be controlled so that the air volume can be adapted to suit the specific requirements, which also results in further substantial energy savings.

Thanks to the successful interaction of motor, electronics and aerodynamics, ebm-papst’s EC fans do not just convince with respect to their energy efficiency. They also work extremely quietly thanks to their optimised commutation techniques and the aerodynamic configuration of the impellers. And on top of everything, they also convince with their reliability and durability.

Directive for motors

EC motors (green) substantially exceed the efficiency level required by the directive for AC motors (other colours)

What applies to fans also applies in principle to electric motors. In this context there is often a lack of clarity leading to misunderstandings. The fact is that electric motors are required to achieve at least efficiency class IE2 from June 2011 in accordance with European Union directive no. 2009/640/EC (ERP directive). Only then will these motors be permitted to remain on the market in Europe. However, not all of the standard motors today will be affected by this directive. The directive defines a “motor” as an “electric single speed, three-phase 50 Hz or

50/60 Hz, squirrel cage induction motor that has 2, 4 or 6-poles, a rated voltage of up to 1000 V and a rated output between 0.75 kW and 375 kW”. EC external rotor motors like the ones used to drive energy-efficient fans are therefore not subject to this directive. Nevertheless, their efficiency can still be compared to the values stipulated in the directive. Here, it becomes clear that EC motors already substantially exceed the efficiency levels demanded. This shows that EC motor technology is the better alternative when planning energy-efficient devices and installations.

Leave a comment