The monastery cellar is located in the middle of the old city center in Beutelsbach, Germany. It includes a gym with showers and changing rooms, which are used by the nearby school, a small cinema, and

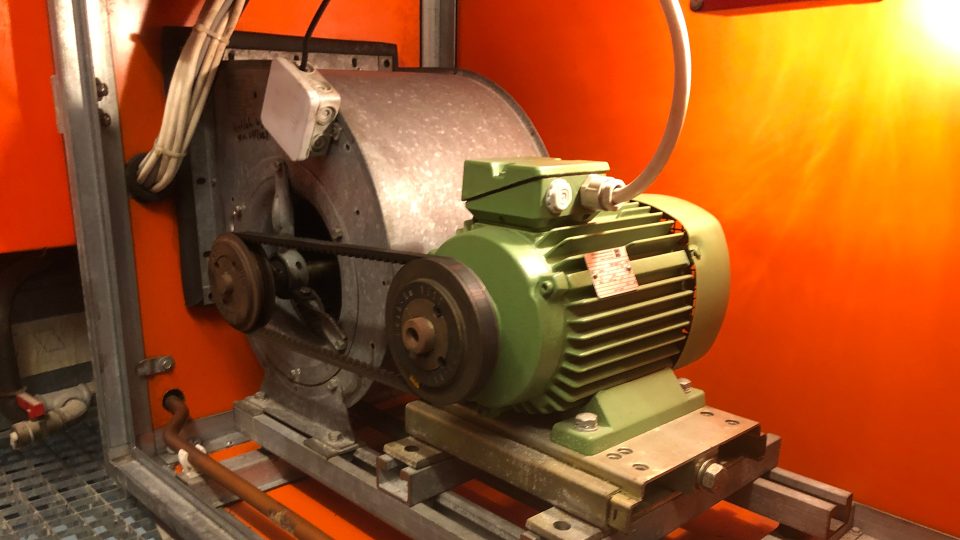

a large vaulted cellar where events take place. These four rooms were supplied with fresh air by a ventilation system located in a narrow cellar room, using belt-driven fans. They could be controlled in just two stages. However, as the rooms were often used to varying extents, for example the cinema room often went from empty to full of people, this is a key area where more efficiency can be gained.

Therefore, the city of Weinstadt commissioned an engineering firm and Pfänder GmbH to find an energy-saving and economical solution (Fig. 1). The city’s wish was initially only to modernize the control system. “That wouldn’t have been a problem either – the system’s control cabinet was in very good condition. However, the energy-saving potential would have been limited due to the old belt-driven fans,” says Lukas Pfänder, Managing Director of Pfänder GmbH.

As Lukas Pfänder had already implemented several successful retrofit projects in cooperation with the ebm-papst Breuell & Hilgenfeldt service center, he also suggested a retrofit for the monastery cellar. The lack of space meant that a plug-and-play solution was the only way to modernize the ventilation system’s intake and exhaust air economically and to reduce the power consumption of the fans.

Retrofit with a focus on air quality

Dieter Hildebrandt, Sales Manager at Breuell & Hilgenfeldt, calculated the required performance and suggested eight RadiFit EC centrifugal fans as a replacement. However, the monastery cellar’s special requirements – the fast change in the level of utilization of the space and the resulting changing demand for fresh air – gave Hildebrandt and Pfänder the idea of equipping the ventilation system with sensors and gateways in order to constantly monitor the requirements and regulate the system to them accordingly (Fig. 2, Fig. 3 in gallery).

Our goal was to reduce the power consumption of the ventilation system by at least 60 percent.

Lukas Pfänder, Managing Director Pfänder GmbH

They approached Ralf Braun, Sales Director Germany and contact person for ebm-papst neo, with this suggestion. The start-up of the fan specialist ebm-papst offers intelligent solutions for data-based buildings. Braun was immediately convinced by the idea, as demand-based, sensor-based closed-loop control would open up more energy-saving potential, alongside the efficient fans.

The RadiFit – the compact solution for ventilation technology

The main aim of the retrofit was to save energy, which is why the RadiFit EC centrifugal fan was chosen, the new system solution for ventilation technology from ebm-papst. Due to its compact dimensions, it was suitable for the installation dimensions of the old fans, enabling space to be saved and the installation to be quick and easy. As it was supplied as a plug-and-play design, it was also easy to connect the electronics.

The RadiFit features a scroll housing and backward-curved blades, which enables a high pressure increase and ensures a high level of efficiency. The RadiFit is also maintenance-free and durable, which further reduces the operational and life cycle costs. The maintenance supervisor and the city benefit from this equally. Thanks to their high efficiency, the retrofit also pays for itself very quickly. Dieter Hildebrandt and Lukas Pfänder estimated energy savings of 60 percent with the eight new RadiFit.

Energy saving thanks to EC motor

This value comes primarily from the RadiFit’s GreenTech EC motor. Such high savings are possible thanks to the efficiency level of over 90 percent alone. Because the old belt-driven AC fans could only be switched on or off, regardless of the actual capacity utilization of the different rooms, the system always ran at too high a power, even if a lower air flow would have been sufficient for the actual fresh air requirement.

We have tailored the control system perfectly to the requirements of the monastery cellar to save even more energy.

Lukas Pfänder, Managing Director Pfänder GmbH

The new, communication-capable EC fan, on the other hand, is infinitely variable between 0 and 100 percent. This means that the new RadiFit can accept any speed as required and operate with the lowest possible power consumption at any operating point. The savings target of 60 percent was already achieved by replacing the fans – but there was still room for improvement.

Demand-based control with sensors

The second part of the retrofit involved reworking the control system. After all, it becomes even more efficient if the demand for fresh air is precisely determined and controlled automatically accordingly. The changing conditions of the monastery cellar provided the perfect case for this.

“The gym is not used for half of the day. However, if a school class has a sports class, the CO2 content rises and the ventilation system has to supply more fresh air. After the lesson, the showers and changing rooms are used, which suddenly increases the temperature and humidity there,” explains Pfänder.

For this reason, sensors for CO2 content, humidity, temperature and fine dust concentration have been installed in the monastery cellar. The measured values are sent to the IntelliGate Air Gateways from ebm-papst neo, which forward them to the ventilation system’s control system. The closed-loop control has been individually adapted and programmed for the monastery cellar. Specially defined limit values now specify when the system increases its power by how much and when it reduces the power once again, with infinite variations and efficiently. Individual functions such as a warning e-mail to the caretaker, have also been set up if a certain value is exceeded (Fig. 6).

The interaction between sensors and systems is reliable and economical. This will enable more than the planned and achieved energy savings of 60 percent. The city not only saves on costs but can also guarantee high air quality for all visitors at large events, festivals or concerts.

Ensuring air quality with the multi-IAQ sensor

With the Multi-IAQ sensor from ebm-papst neo, there is a simple and efficient way of ensuring consistently high air quality in event rooms. The sensor measures a total of five values, namely temperature, humidity, VOC (volatile, organic compounds that are harmful to health), CO2 and fine dust in the air. The viral index is calculated using the five measured values and a complex mathematical equation. This indicates the quality of the air and the risk of virus transmission and can be read off from the freely accessible IAQ Connect app. The multi-IAQ sensor can be installed in flush-mounted sockets similar to a light switch.

Leave a comment