What has been discussed in traffic and in factory halls for years is only gradually drawing more attention in other areas: Noise produced by air conditioning or cooling of rooms. For employees in offices, neighbors of supermarkets, hotel guests, or residents of a building with residential ventilation or heat pumps, permanent noise pollution has a negative impact on performance and quality of life. And noise emissions in ventilation and air conditioning systems are not always obvious: If we immediately notice noise levels above a certain level of decibels as unpleasant, for example, low-frequency noises are not always so easily noticeable, but they have equally large effects.

Understanding noises, their causes and effects is therefore extremely important for improving the acoustics of ventilation systems. Responsible manufacturers of systems and components rely on instruments that consist of measurement laboratories, psychoacoustics, and aerodynamic development in order to create ever quieter and more compatible solutions. The fans are aerodynamically – and thus often aeroacoustically – optimized, driven by quiet-running EC motors, as well as guard grills that have a positive effect on the air flow before and after the impeller.

Noise can be subjective.

We take you on a journey into the world of noise. Join us in the acoustics laboratory, learn more about the effects of noise on people and what this has to do with quiet EC fans.

The noise spectrum of a fan

The noise spectrum of a fan generally includes tonal and broadband components. The ways in which these components arise are completely different: The cause of most tonal components is the interaction of the rotating impeller with disturbances in the adjacent air flow. These are caused by struts, guide blades, asymmetric inlets and other on-site components.

A look inside the measurement laboratory

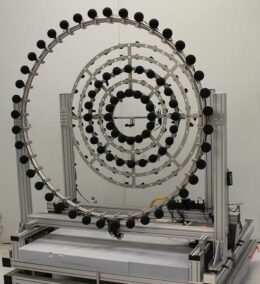

Tracking down sound sources in fans is not an easy task. One example of an experimental method of localizing sound sources on a rotating fan is the so-called beamforming process.

At the heart of this is a circular microphone array with 80 microphones arranged on two levels. The microphone array is used on the intake side of the fan test bench.

There, it measures the runtime differences between the sound waves and the individual microphones. Sophisticated algorithms then evaluate the data.

Their origin thus depends on how the fan impeller is installed. Often, they can be reduced or even prevented by improving the placement of the impeller. In contrast, most broadband noise components are caused by unavoidable turbulence in the inflow and the inherent flow around the blades. The broadband components determine the base level of a fan’s noise spectrum.

The solutions developed by ebm-papst to combat noise generation include aerodynamically optimized impellers, winglets, diffusers and air inlet grills with which the sound power level and noise levels of the fans drop considerably. Aeroacoustic testing has thus proven its worth as a means of optimizing fans.

The RadiPac series for ventilation technology

One example of this is the centrifugal fan in the RadiPac product range, which is specially designed for use in air conditioning and ventilation units. The new generation of centrifugal fans operates at higher efficiency levels and with lower noise levels. Depending on the operating point, the noise level reduction is between 3 and 7 dB(A) compared to the predecessor series.

To bring about this optimization, the impeller plays an important role. It has been developed according to the latest aerodynamic findings with its five geometrically sophisticated impeller blades. A high-strength, glass-fiber reinforced composite material is used here. The complex shape is made possible by the injection molding process used. This blade geometry drastically reduces flow losses.

FlowGrid for additional noise reduction

The FlowGrid acts as a kind of rectifier that reduces noise-generating turbulence in the inflow without changing the air performance and power consumption.

It is also possible to use Flowgrid as a guard grill for the intake side. The fans are then even quieter. Good results can be obtained here in noise-sensitive applications such as heat pumps, residential ventilation units and air purifiers for classrooms.

ebm-papst has not only optimized the geometry and material, but also taken into account the actual installation situation in AHUs. The wide optimum efficiency range of centrifugal fans means that the fans operate at practically every operating point with the lowest possible power consumption, and there are also no unpleasant surprises in terms of noise levels.

How do we perceive fan acoustics?

Learn more about it in this What the Tech?! video.

Reducing noise: Involving experts in planning

Noise development in ventilation systems has a multifaceted effect on the people concerned. However, this problem can be reduced greatly by taking different factors into account. It is crucial to involve component manufacturers in the planning and development of a system. This is particularly true of the fan, which, as a rotating part of the system, can be a central source of noise.

On the one hand, ebm-papst takes into account the wide range of influencing factors in terms of noise development and uses complex measurement technology and the findings of psychoacoustics in order to make every generation of its products even quieter – and thanks to these aerodynamic developments, it is always much more efficient.

Leave a comment