When it comes to centralized units for home ventilation, the market trends towards backward-curved centrifugal fans. There is a good reason for this: The RadiCal centrifugal fans in the aerodynamically optimized scroll housing from ebm-papst have been specially developed for use in home ventilation units (Fig. 1).

Figure 1: RadiCal centrifugal fans in a scroll housing optimized for aerodynamics are available for use in central residential ventilation units, here with an additional FlowGrid air-inlet grille on the intake side.

This achieves an energy efficiency improvement of more than 30% in comparison to forward-curved fans, which are still widely used in ventilation units.

The improved energy efficiency is based on the combination of RadiCal fans with a scroll housing optimized for aerodynamics. The extremely efficient GreenTech EC motors also contribute towards energy efficiency.

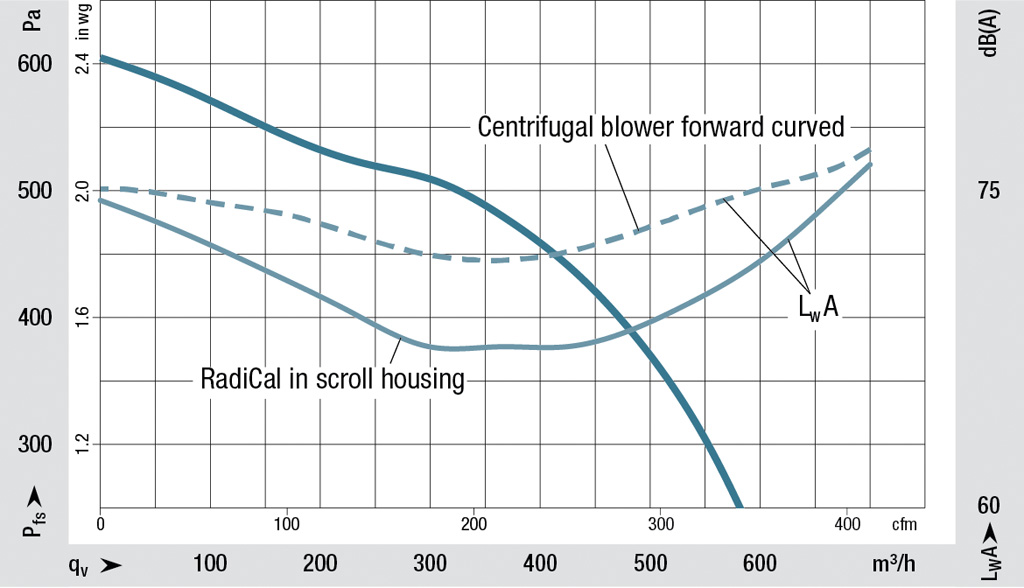

The round outlet of the new scroll housing fits directly onto the pipes that distribute the air. This reduces airflow losses in the pipe system. The noise level is also reduced by up to 3.5 dB(A) when compared to a centrifugal blower, as has been confirmed in numerous tests (Fig. 2).

The disturbing tonal noise of a backward-curved impeller in a living environment has been significantly minimized through the combination with the optimized scroll housing. The tonal proportion in the disruptive frequency range is reduced by up to 20 dB in comparison to conventional installation conditions.

Figure 2: The noise comparison shows that the RadiCal in the scroll housing (continuous line) is quieter than a centrifugal blower fan (broken line) by 3.5 dB(A).

Furthermore, the fan can be mounted very easily in the ventilation unit via the discharge flange and even combined with the FlowGrid air-inlet grille, which can be mounted on the intake side. This reduces the turbulence caused by fittings in the unit, thus further minimizing the noise emissions.

Integrated volume constancy control

Figure 3: Plug & Play – solution: The blower optimized for aerodynamics includes a control electronics system as well as sensors to detect the air volume, temperature, and humidity.

Due to physical factors, the volume flow control in backward-curved centrifugal fans is more costly than in forward-curved fans.

However, ebm‑papst has a ready-to-install plug & play solution for this: An impeller manometer positioned in the outlet of the scroll housing (Fig. 3) continuously records the actual air flow and transmits the data to the integrated central electronics system of the fan.

This central electronics system adapts the speed of the EC motor to the desired setpoint value, thus regulating the air volume (Fig. 4). Thanks to the impeller manometer (patent pending), the air flow can be regulated with an accuracy of +/‑1 % (to the end value) in an air performance range from 50 m³/h to 500 m³/h (Fig. 5). This is significantly more accurate than the systems currently available on the market.

Figure 4: The central control electronics of the fan regulate the air volume depending on the ACTUAL air flow recorded using an impeller manometer positioned in the air flow.

In this application, a significant advantage of EC fans is that they retain their high efficiency and control accuracy even in partial-load operation.

The integrated volume constancy control enables effective home ventilation without an overpressure or underpressure occurring in the living space. This prevents humidity in the walls and unwanted cold air supply from outside.

The additional impeller does not result in any air performance losses or disruptive noise, meaning that the overall performance of the fan remains unchanged. Even contamination is not a problem, as has been demonstrated in tests under extreme conditions with dust and increased air humidity.

Comprehensive sensor system and communication via MODBUS-RTU

The central electronics integrated in the blower offer even more options in addition to the motor control and volume flow control. Through the integration of a sensor in the blower outlet, it is possible to directly record the humidity and temperature of the supplied air. Furthermore, three additional external sensors can be optionally connected (Fig. 6). There are two analog inputs and one digital input (I2C) available for this. Another 0‑10 V input enables the connection of CO2 or VOC sensors to record air quality, for example.

With this wide range of options for recording air quality, the ventilation in living spaces can be optimally controlled to provide a pleasant interior climate. Alongside the values detected by the sensors, it is also possible to record the operating data of the motor via the central fan electronics. This enables recording of the running time of the blower in order to determine when the filter needs to be changed, for example. All information can be communicated conveniently via the MODBUS-RTU interface. Alternatively, a 0-10 V interface is also available, which the user can use to control the fan speed as desired.

The fan is the intelligent “heart” and central information source of the controlled residential ventilation system. It is therefore much more than just a fan that supplies air.

Figure 5: Examples of volume constancy control stages. Thanks to the impeller manometer (patent pending), the air flow can be regulated with an accuracy of +/-1 percent (broken line) in an air performance range from 50 m³/h up to 500 m³/h.

Perfectly equipped for the EU Ecodesign Directive

Figure 6: The central control electronics process the signals of the connected sensors, control the motor, and communicate all data via the MODBUS-RTU interface with the device control of the residential ventilation system.

The RadiCal centrifugal fans in scroll housings are offered in size 190 with various output levels up to 170 W depending on the rated air performance of the ventilation units. The series is being expanded to include further sizes and versions. In addition to the EC versions, an AC version without sensors is also available for applications that require less energy.

However, in most cases it may make sense to use the energy-efficient EC technology that can be regulated as required. This is necessary if the intention is to achieve the highest possible energy rating label for the end device.

Since January 2016, the EU Ecodesign Directive has stipulated that ventilation units with heat recovery must save as much primary energy as they consume, and must bear the corresponding energy label. The requirements in this regard are set to tighten further in 2018 and 2020.

Leave a comment