Waste incineration is not exactly something that makes people think of improved air quality. But in the community of Hinwil in the Swiss canton of Zurich, the two aspects are being combined in a project that’s unique worldwide. On the ground, a local waste management authority converts trash to slag by burning; above, Climeworks turns carbon dioxide into plant food. It’s an efficient cycle as the waste incineration provides energy for the CO2 extractors on the roof. They bring the greenhouse gas via a pipeline to a greenhouse 400 meters away, where a nursery uses it to boost the growth of cucumbers and tomatoes. The process turns 900 tons of CO2 from a climate nemesis into a growth booster.

From dream to climate target

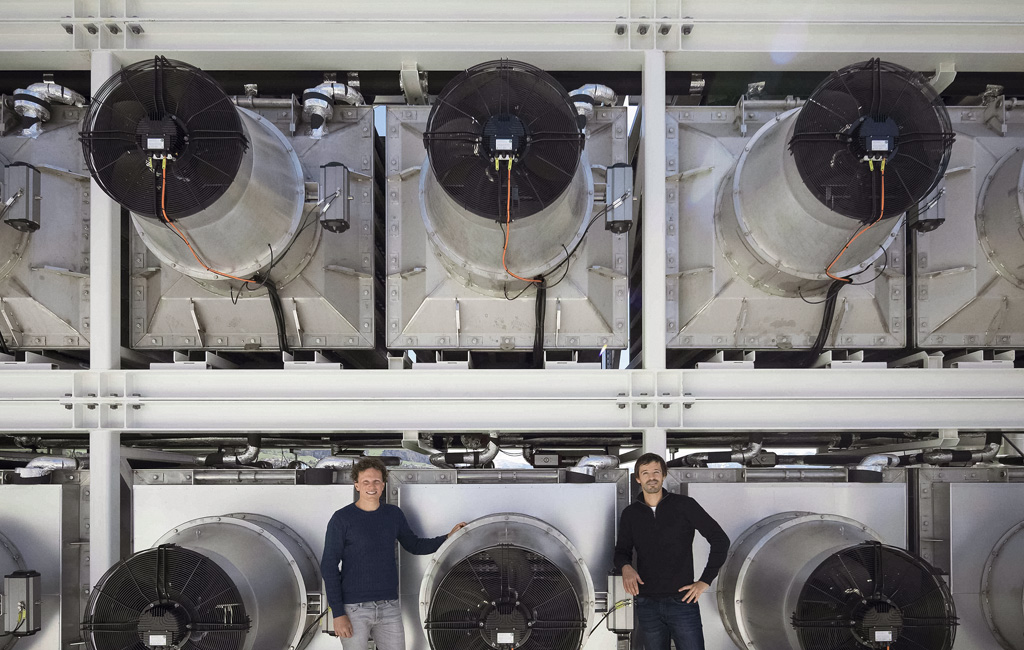

The technology is called direct air capture (DAC) and the plant was developed by Christoph Gebald and Jan Wurzbacher. The two engineers became acquainted early in the millennium during their studies at the Swiss Federal Institute of Technology in Zurich. “We decided on the first day to found a company together,” says Wurzbacher. “That was our big dream.” In 2007 they began research on technologies for extracting carbon dioxide from the air. Just two years later, they founded Climeworks.

The company has set itself some ambitious goals: “Technologies for removing CO2 from the air are indispensable for reaching the two-degree target,” says Valentin Gutknecht, Marketing Manager at Climeworks. The company would like to see one percent of worldwide CO2 emissions being filtered out of the air by 2025. Doing that would take 250,000 plants like the one in Hinwil. It consists of 18 extractor units that are controlled and monitored together. The advantage of its modular design: It needs little space, is easily scalable, and can therefore be used anywhere.

Useful CO2

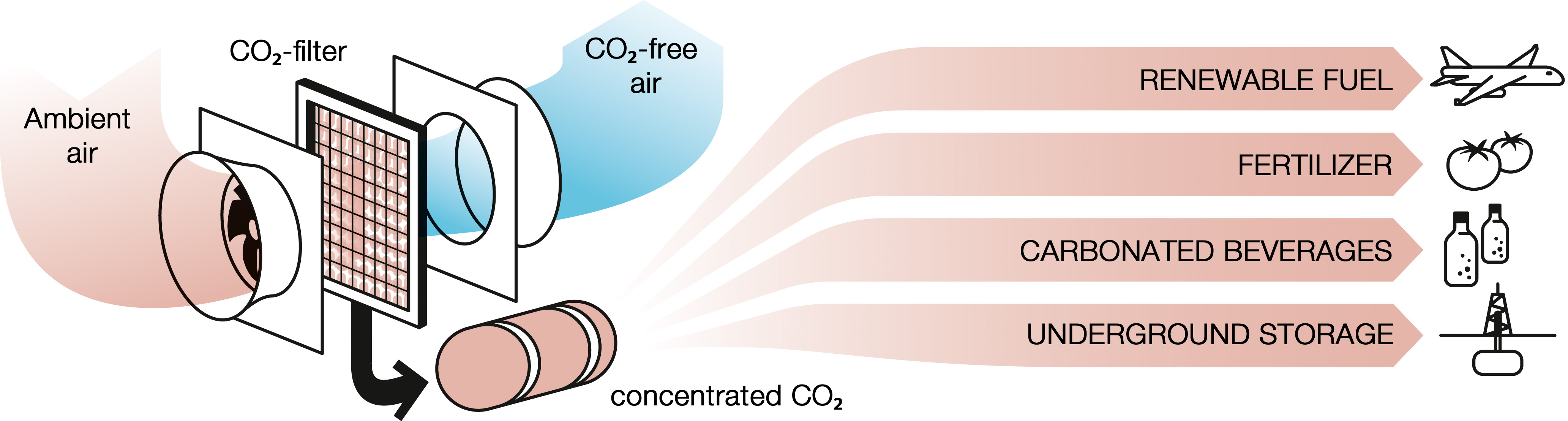

The carbon dioxide filtered out of the air by the direct air capture plant can be used for many things, such as renewable fuel, fertilizer and carbonation in beverages.

The basic principle of the CO2 extractor is actually quite simple. A fan draws in air through a filter that captures the CO₂. When the filter is saturated, the carbon dioxide is separated at 100 degrees Celsius. Of course choosing the right process and components was somewhat more complicated. “Energy efficiency was a very important aspect for us; we had an eye on it from the beginning,” says Wurzbacher. That was a reason for Climeworks to choose large axial fans from ebm-papst. They have to transport very high air flow with low pressure losses and also be very quiet. “We benefited from being able to set up and measure the entire system at ebm-papst in Mulfingen. That helped us to maximize the efficiency.”

“Removing CO2 from the air is indispensable for reaching the two-degree target.” Valentin Gutknecht, Marketing Manager at Climeworks

Climeworks is also working on the efficient use of the carbon dioxide. Growing vegetables as in the initial project in Hinwil is only one of several possibilities. The CO2 harvested in the DAC plant can also be used for the production of carbonated beverages or climate-neutral fuels and materials. The main thing is that it disappears from the atmosphere.

Leave a comment