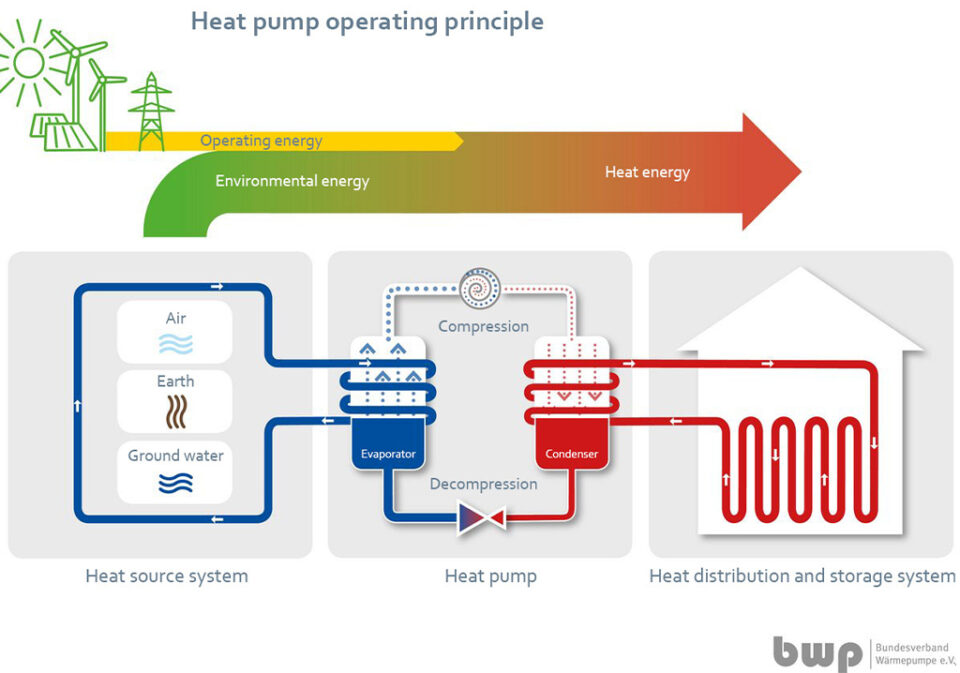

Today’s heating systems demand concepts based on renewable energies. Therefore, heat pumps are becoming ever more popular in both new buildings and renovations and are subsidized by funding in many cases. They are becoming an important pillar in creating more sustainable heat generation. Today more than half of new construction projects are equipped with this. Air-to-water heat pumps are widely used here due to their efficiency and their simple installation and set-up. They use heat energy from the ambient air and transfer it to the hot water circuit via an intermediate circuit with refrigerant (Fig. 1).

Fig. 1 | Air-to-water heat pumps use the heat potential from the ambient air and transfer this to the hot water circuit via an intermediate circuit with refrigerant (creator: Bundesverband Wärmepumpe e.V.)

What fan options are there?

However, the step-by-step plan of the F-Gas Regulation (Regulation (EU) No. 517/2014) governs the use of partially halogenated hydrofluorocarbons (HFCs) (Fig. 2). So in the long term, there is no way around the natural alternatives. However, these are flammable in most cases.

The reason for this is simple: a low GWP value requires a rapid decomposition of the refrigerant when it enters the atmosphere. This can only be assured if it is chemically reactive, but high reactivity typically goes hand in hand with a high level of flammability. When developing refrigerating systems and air conditioners, household refrigerators and heat pumps, manufacturers must therefore ensure that they only use components that meet the applicable standards for handling flammable refrigerants.

For fans that provide the necessary air flow in heat pumps through the evaporator, this means that their electronics must not become an ignition source, even if a fault occurs. In principle, this can be achieved in various ways. One method, which is very time-consuming, is using restricted-breathing housings that prevent electronics and flammable atmospheres from coming into contact with one another. Another option is using an additional, smaller ATEX fan, which ensures reliable ventilation of the unit. However, this principle of continuous ventilation is only rarely used, e.g. in chillers. Most manufacturers of air-to-water heat pumps prefer to use components that are approved for use with flammable refrigerants.

Fig. 2 | The step-by-step plan of the F-Gas Regulation (Regulation (EU) No. 517/2014) governs the use of partially halogenated hydrofluorocarbons (HFCs). (Graphic | ebm-papst)

Drive design in accordance with EN 60335-2-40

Using ATEX-approved fan motors is always possible but they are often oversized and expensive. Motor and fan specialist ebm-papst therefore offers an alternative specially designed for use in air-to-water heat pumps. For selected fan drives in sizes 55, 74 and 84, the electronics circuits have been modified to comply with EN 60335-2-40 for heat pumps with flammable refrigerants, i.e. the maximum surface temperature must be at least 100 kelvin below the ignition temperature of the refrigerant used in the event of a fault.

Propane, which is very well suited to new buildings and building renovations due to its good heat transfer capacity and its low GWP value, has an ignition temperature of 470 °C. The electronic assemblies, which have been tested and certified accordingly, ensure that their maximum surface temperature always remains below 370 °C, even if a fault occurs, and as a result they do not become an ignition source.

The fans approved for use with A3 refrigerants in accordance with EN 60335-2-40 with maximum fill quantities of up to 1 kg or 5 kg (depending on the installation site) are available in many axial and centrifugal variants, covering the widest variety of applications for air-to-water heat pumps for outdoor use and for indoor use.

High energy efficiency and low noise emissions

Energy efficiency and noise characteristics are also important aspects when selecting fans for heat pumps. Modern EC motors are the driving force behind the fans. Users benefit from GreenTech EC technology in several ways: One of them is thanks to its energy efficiency. When generating the desired heat output, heat pumps should consume as little primary energy as possible. The compressor consumes much more power than the fan, but it still pays to have the fan work at the highest possible efficiency. That is why there is no alternative to EC technology here too (Fig. 3).

Fig. 3 | When providing the desired heat output, heat pumps should consume as little primary energy as possible. It pays off if the fan operates at the highest possible efficiency (green characteristic curve ‘RadiCal’ with GreenTech EC technology, red characteristic curve for conventional centrifugal fan with AC technology: P1=Power consumption, Pfa=Air performance curve) (Graphic | ebm-papst)

Another advantage, the noise characteristics of the EC fans, becomes particularly important at night when the limit values of the applicable legal regulations must be observed inside and, most importantly, outside the building. To keep noise emissions low, large fans should operate in the low speed range as far as possible. It goes without saying that the EC motors used in the fans are easy to control, as the speed can be further reduced at night without a problem.

This means that switching off the heat pump to avoid trouble with the neighbors is not necessary. If the speed of the example fan is reduced by just 100 rpm, the noise can be reduced by more than half (Fig. 4).

Fig. 4 | Dependency of sound pressure on the speed with a centrifugal fan. If the speed of the example fan is reduced by just 100 rpm, the noise can be reduced by more than half. (Graphic | ebm-papst)

Good interplay between fan impellers or blades with the motor and electronics is another key element for quiet fan operation. ebm-papst has optimized its blade and impeller geometry to achieve considerable improvements in aerodynamic efficiency and noise emission. Psychoacoustic aspects were also taken into account to ensure that fan noise comes across as pleasantly as possible. For quiet operation, the fans can usually be combined with guide vanes.

This FlowGrid reduces noise resulting from the conditions of installation. This ensures that the heat pumps operate quietly at all times. The range of fans that meet the applicable standards for flammable refrigerants is being continuously expanded so that a suitable design can be found for each performance class.

Leave a comment