Medical technology is a broad field and many of its applications need drive systems, including dental chairs (Fig. 1) with their adjustable headrests, diagnostic equipment and CT scanners (Fig. 2), X-ray and physical therapy equipment, lighting systems for operating rooms, and automated positioning units in operating tables, stair lifts and the like. Such applications often call for compact drives with relatively low power that have to work very reliably and with high positioning accuracy.

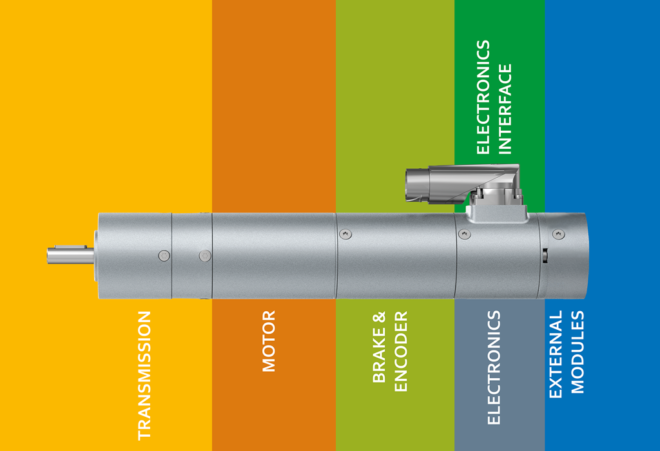

Durability, quiet operation, a wide range of speeds and precise speed control are additional requirements to be met. For such cases, users are well advised to use the configurable ECI-42 drives from drive specialist ebm-papst. The modular system for drives enables customers to put together customized variants by combining various tested and validated modules such as brakes, encoders, etc. (Fig. 3).

42 mm motor, transmission, brake and encoder

Figure 1: Medical equipment often needs compact and relatively low-powered drives, for example for various adjustments on dental chairs.

A great deal of application expertise is involved in the development of compact, electronically commutated, brushless internal rotor motors. This makes them perfect for use in medical equipment, and their users benefit from complete drive solutions from a single source. High power density makes the drives very compact, which is helpful when designing equipment as it often enables more compact dimensions.

At the heart of all the configurations is a brushless, electronically commutated internal rotor motor with a diameter of 42 mm and stator lengths of 20 or 40 mm. It achieves output levels of around 45 or 90 watts at a nominal torque of 110 or 220 mNm and a nominal speed of 4,000 rpm. Its efficiency rating is up to 80%. The motors come in standard designs of 24 and 48 VDC safety extra-low voltage. Hall sensors for rotor position detection are integrated, and the motor is actuated by an external, closed-loop controller. Integrated electronics modules with functionality such as speed or position control with optional bus interface are already in development.

Transmission and brake modules for various requirements

Figure 2: CT scanners need reliable and quiet drives to minimize noise emissions.

Various transmission modules are available to reduce the high speed of the internal rotor drives and bring the drive torque to an appropriate level for the application. Along with planetary and spur gears with various reduction ratios, space-saving EtaCrown crown gearheads based on innovative crown-gear technology can also be supplied, for example. The NoiselessPlus 42 planetary gearhead guarantees ultra-quiet operation and with the Optimax 42 transmission (Fig. 4), there is now an extremely rugged, overload-proof one- or two-stage planetary gearhead with IP50 or even IP54 degree of protection that also works with the small 42 mm drives.

If the application in question demands holding or safety brakes for quick emergency stop or, for example, to safely maintain the position of lifting equipment in the event of a power supply failure, modules with permanent-magnet or spring-operated brakes can be added to the drive unit, ruling out risks for the patient. In this way, positions can also be held precisely and securely over longer periods for X-rays.

Measuring positions with high-resolution encoders

An encoder module can be integrated in the drive unit for precise position measurement. Its magnetic incremental encoder works with a resolution of 12 bits, which increases depending on the selected transmission solution so that a precision of up to 0.08 degrees can be achieved at the output shaft. Optional lower resolutions are also possible.

Figure 3: The ECI-42 modular system for drives enables customers to put together customized variants by combining various tested and validated modules.

In the next stage of development, there will be an absolute multi-turn module (up to 17-bit resolution in the single-turn and up to 32-bit in the multi-turn range). The rotation counter works without batteries, instead using an energy-harvesting system based on the Wiegand effect so that the energy needed to store the rotation information is generated from a rotating magnetic field. That makes backup batteries, transmissions and related maintenance work unnecessary.

Practical connectors

Figure 4: With the Optimax 42, there is now an extremely rugged, overload-proof one- or two-stage planetary gearhead with IP50 or even IP54 degree of protection that also works with the small 42 mm drives.

Customized 42 mm drives put together using ebm-papst’s modular system for drives meet the requirements for IP50 or IP54 degree of protection and provide a variety of options for electrical hookup. These include industry-standard connectors, in which the radial angled plug with bayonet connector can rotate and engages automatically. An axial plug is available for space-critical applications; an alternative, preassembled cable connection is also possible.

The industrial-grade drives are ideal for practically all medical equipment applications that require energy-efficient small drives. Thanks to defined preferred types, selected drive configurations can be delivered within 48 hours, which means that sampling, for example, can be done very quickly. The drives can be configured and ordered via the online portal idt-config.ebmpapst.com.

Leave a comment